The car was involved in a mishap. I purchased an HO scale welding team that will be working on fixing the railing. It’s going to look awesome.

Excellent, keep us posted.

Rich

Looks like my questions of the contracted layout in the silo, personal layout, and outcome of the custom painting of the loco are being ignored…

I think you missed his response to your question about 4 posts up. It happens, I read Jeffreys Diner regularly and I swear new posts seem to appear in the middle of old posts.

Uh oh, maybe Scratch is being monitored. [(-D]

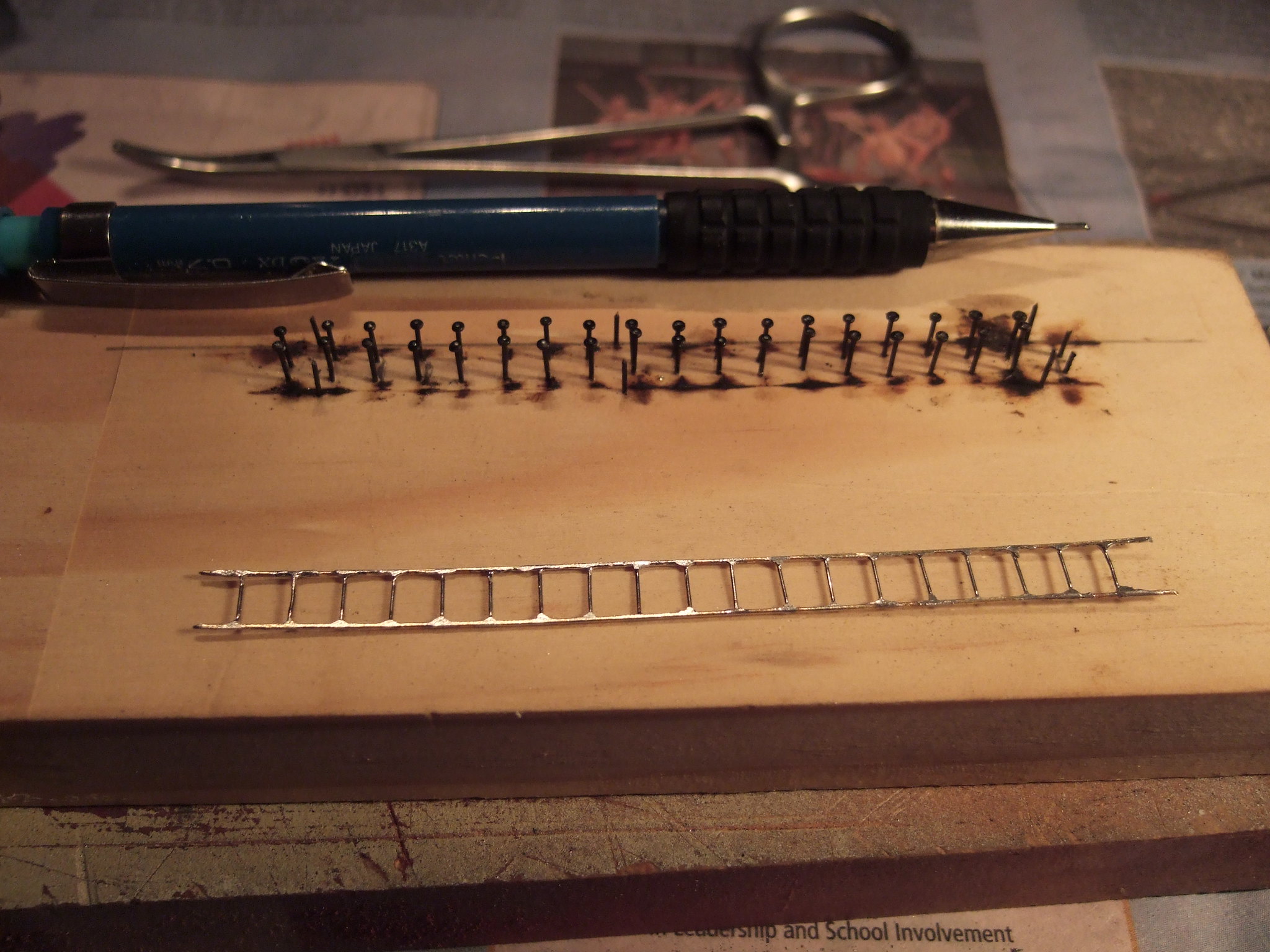

You’ve probably finished the railings, but if not, I would suggest a small jig might help. Here’s my HO scale ladder jig.

Cheers, the Bear.[:)]

I was just thinking about how to do this! Nice job, I’ll do the same! DJ

Ha, I need to revert to my Chicago educated directness in my communications…

To rephrase my oblique questions:

-

What is the status of the contracted layout to be built in/at the “silo”?

-

How is your personal layout coming along (i.e. design, benchwork, etc.)?

-

What has stalled the loco painting? I don’t understand why - unless the results were less than satisfactory and not up to supposed “forum expectations”…

This thread is about a hopper car. Got something useful to contribute like the Bear?

Ooops, I guess my questions struck a nerve.

They are legitimate questions, harmless in intent, and they seemed OK to post them here, rather than going back to the original threads…

What could possibly be wrong with that?

Put a quick jig together as per your idea. Excellent advice. I’ll modify the jig later today to get the dimensions closer to the ladders on other HO cars. Thank you. DJ

On my way home had a new idea for a jig. This HO ladder fits perfectly onto a breadboard so this will be my new jig. DJ

Working on ‘downgrading’ one end of the car. Real coal from the mine in Springhill, Nova Scotia was sprinkled onto the end of the car from above as though it was being loaded. Note that a ladder is now in place on this end of the car. Lots more to do on the ends and sides.

Once the cement spray dries, the excess coal dust will be brushed off the end of the car - there will not be loose bituminous coal falling onto the track (just if you are wondering). DJ

The inside of the hopper looks pristine. You better dirty it up.

All components installed on the car. Coal dust applied and adhesive spray drying. After drying I’ll clean up loose coal then put the trucks and couplers back on. Finally, a load will be added and then onto the track. DJ

Who made those Ortner car models originally? Walthers, or someone else?

Thanks

if you go to eBay and search ‘ho scale ortner’ you’ll see Walthers cars so I assume Walthers for this particular car. DJ

Yes, definitely Walthers.

Two last pictures to wrap up this thread. First hopper loaded with bituminous coal from the mine at Springhill, Nova Scotia is ready to roll. In total I will do the same with six hoppers, so the second one will be broken down this evening. After that I will move on to barite and manganese ore Ortner hoppers. DJ