Thank you.

A few more facts, maybe obvious, maybe not.

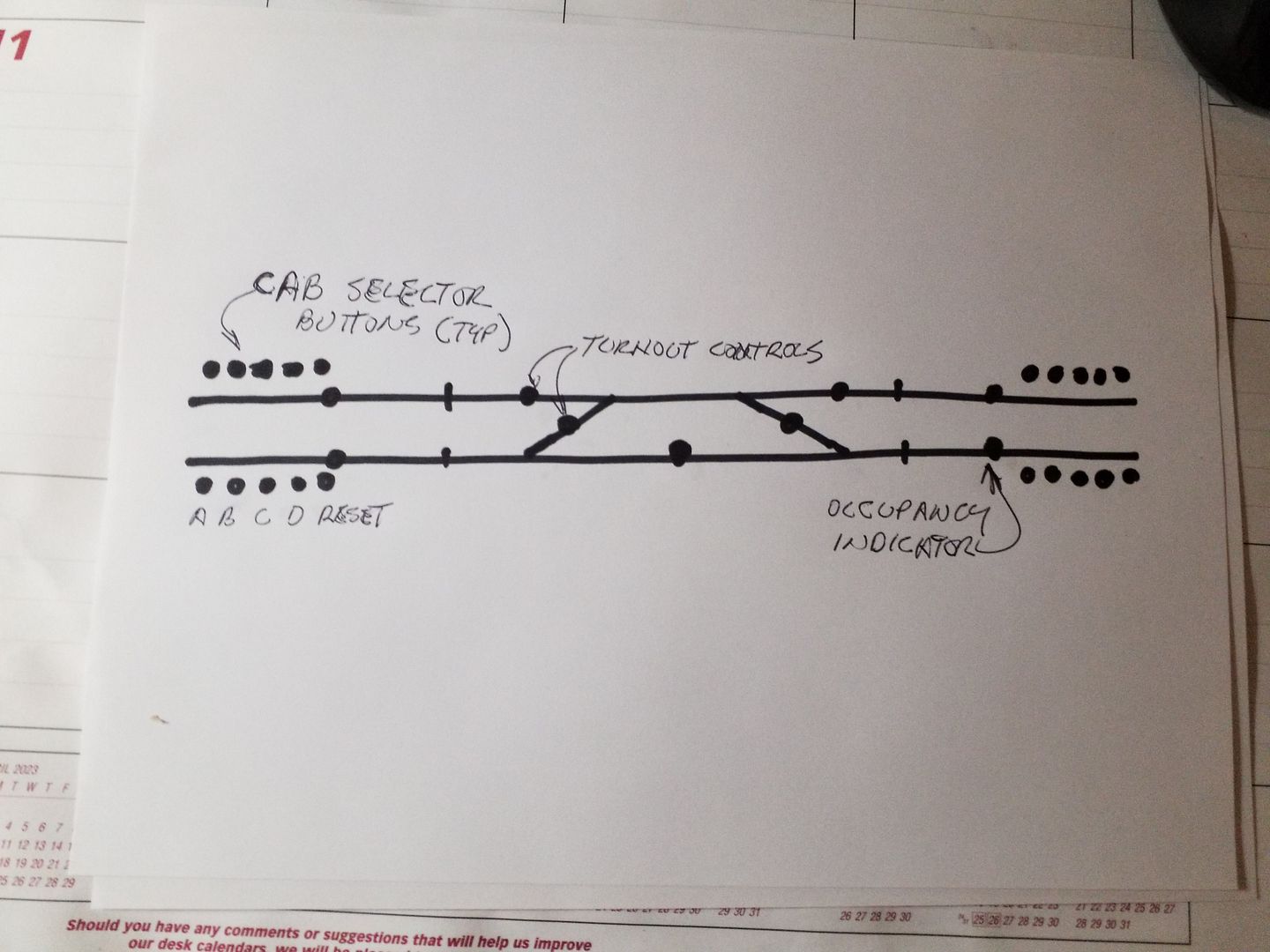

If a block is assigned to a cab, and you push a button to assign it to a different cab, it switches directly to the newly requested cab. So, you do have the personal responsibility to make sure the block is available. That is why there is occupancy indication on each tower panel and the dispatchers panel. But again, with a dispatcher, that is his job, not the engineer.

But this feature allows operators to not be concerned with turning off blocks as they leave them. The dispatcher will reassign them or turn them off as needed, or without a dispatcher the next operator can take the block when the occupancy is clear.

The reset button disconnects the selected cab, leaving the block completely dead.

On system startup no cabs are assigned and all turnouts reset to their default “normal”.

I am considering additional wiring that would lock out the turnout controls if a train is in the interlocking territory - just like the prototype.

Signals that are hard to see will be repeated on the tower panels or overhead occupancy panels as needed. But just like a real dispatchers panel, there will not be repeaters of the signal aspects there. Dispatchers only care where the trains are, how the route is set and who they gave permission to. Their panel tells them all that with a minimum number of lights.

All signals are “Absolute” or “Control point” signals - BUT, there will be approach signals half way thru each block that will give the appearance of permissive bock signals.

Not all signal aspects will be modeled, so in some places there will be a yellow aspect that you will never see lit. Or in the case of those approach signals you will never see the red lit. When their home signal is red, they show yellow, when their home signal is green, they show green.

Interlockings will be speed signaled with multiple heads typical to eastern practices.

There is no att