Maxman, I use Google Chrome to convert between English and Japanese. Are you also unavailable?

Relative to problems with coupler pockets, I feel that MDC/Roundhouse had the best pocket of the high volume shake the box kit makers, with the factory screw on cover.

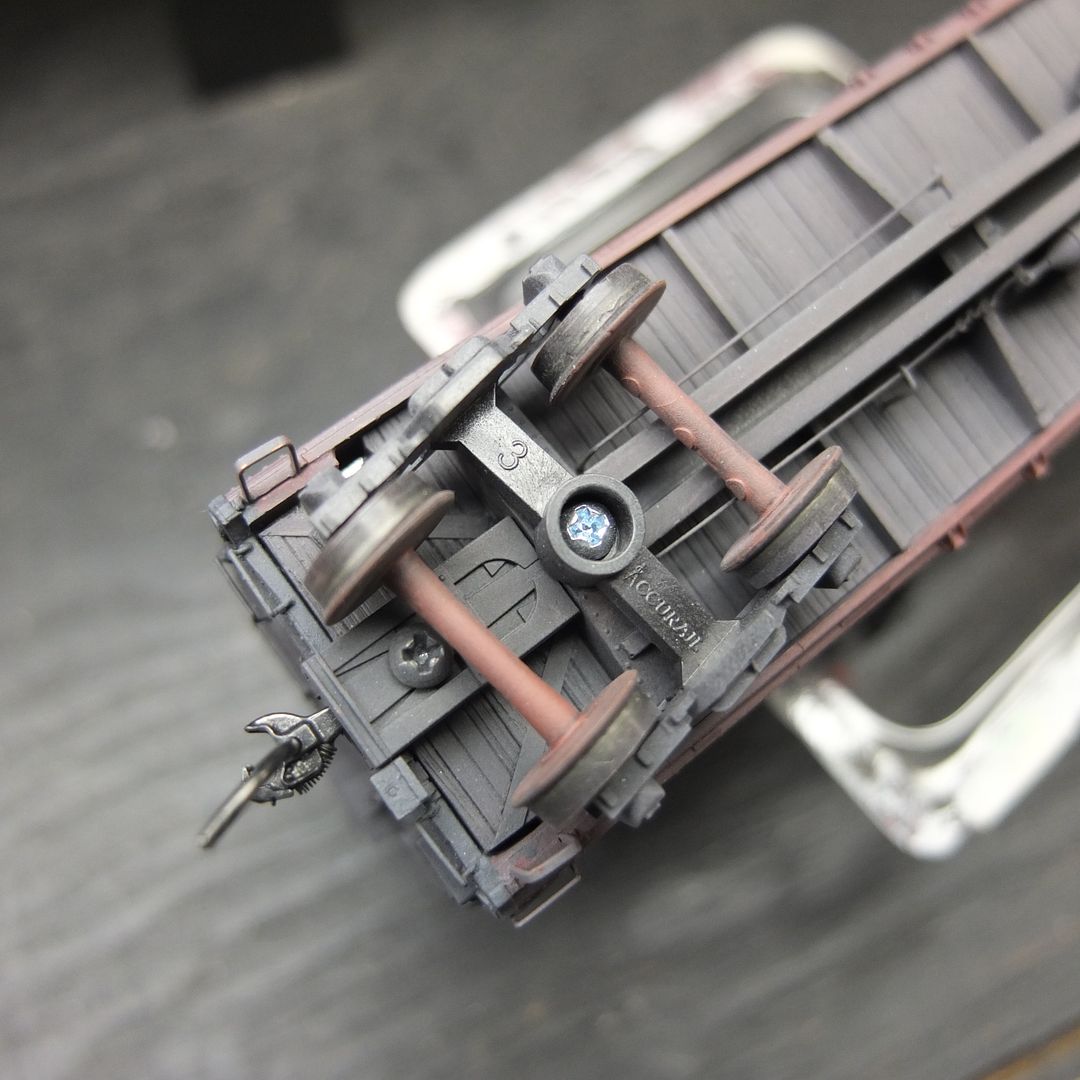

Accurail had the friction pins, Athearn had the hard steel clips (that could shave off the nubbies holding them on if you removed the clips more than twice), and DW apparently has this above issue (which I never noticed, but I only had a few of their cars).

It seems in total, DW isn’t any better or worse than the others. I like the separately applied ladders.

I have Firefox. I don’t know if that has translation capability. I was primarily interested in the coupler box modification with the screw in from the top.

Douglas, Have you experienced the droopy couplers on DW boxcars as described by BN7150? I agree, the MDC coupler boxes are great. Thanks!

I use both chrome and firefox. When you are on the page to be translated, right-click your mouse. In chrome, one of the options is to translate to English. Unfortunately, it does not bring up the translation option in Firefox and I could not find any way to translate in Firefox.

I wouldn’t consider that a major flaw. I simply installed the bronze spring upside down and everything worked fine.

Yes, I know the up-side-down spring prevents the Kadee “delay” feature from working but I don’t use that, and my understanding is that few do.

Never noticed that on the examples I had. I installed the coupler and put everything together and am good. I wouldn’t call it a major flaw either.

The coupler hanging down or being too low is a major flaw with many of the kit models I’ve dealt with including Athearn and MDC.

I’ve used the typical methods of dealing with it, such as shimming the coupler. Also, with the bronze spring on the bottom, that acts a bit like a shim too. Adding a Kadee fiber washer to between the truck and the bolster.

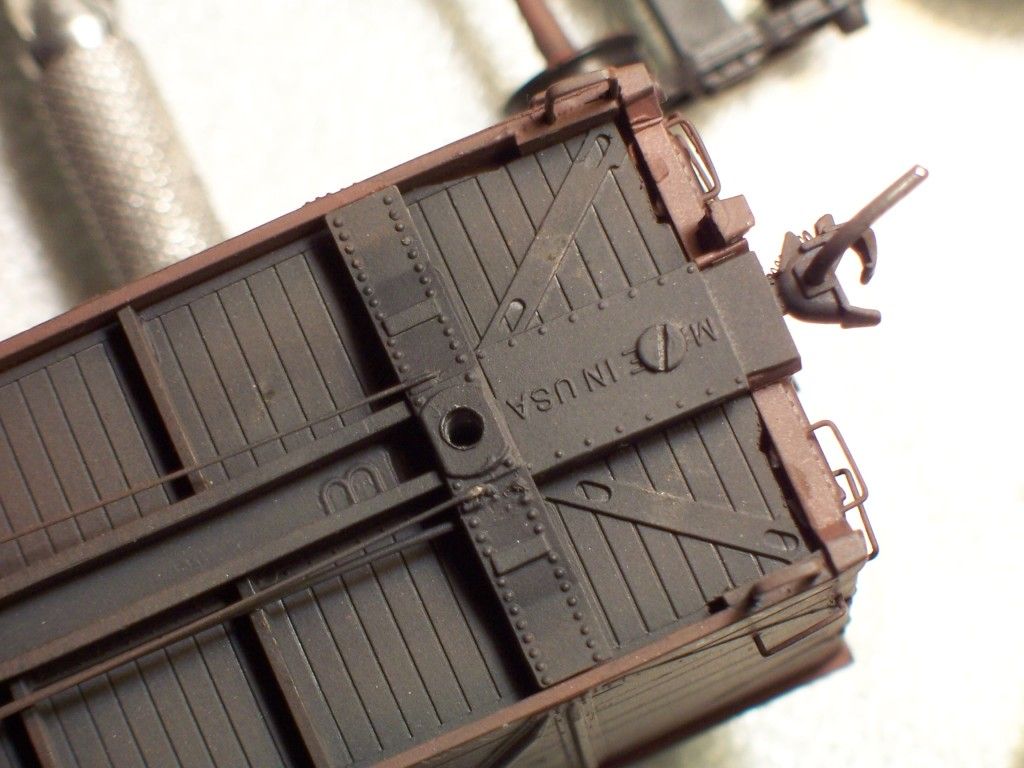

Maxman, I recommend “ultra low head screws.” They are sold at Japanese hardware stores, but one is expensive at $0.20, also should be available in your country. The small screws in the next picture are all M2 x 4 mm, the bottom one is that. The thickness of the head is 0.3 mm (0.012 inch). In order to sink the screw head, you have to counterbore a bit.

Jim,That has always been a pain but,light years better then the old wooden kits of the 50s.

Modelers should recall building a BB car kit took time and lots of tweaking to get the coupler at its correct height the frame was the usual suspect because some was slightly warp enough to cause the droop.Of course the coupler clip had to click into place if the catch on the side of the coupler box wasn’t deformed or in some cases to small to hold the fool clip!!! [banghead] A 2-56 was the answer for troublesome boxes.

I never had much of a issue while building a Roundhouse kit exception being the kits with the metal frame and some filing was needed to remove the flash and some times redrilling the coupler or truck screw hole.[banghead]

Today all we need to do with some brands of cars is simply remove the junk coupler and install the KD coupler of choice. [yeah][tup]

Okay, thanks, I’ll search for those.

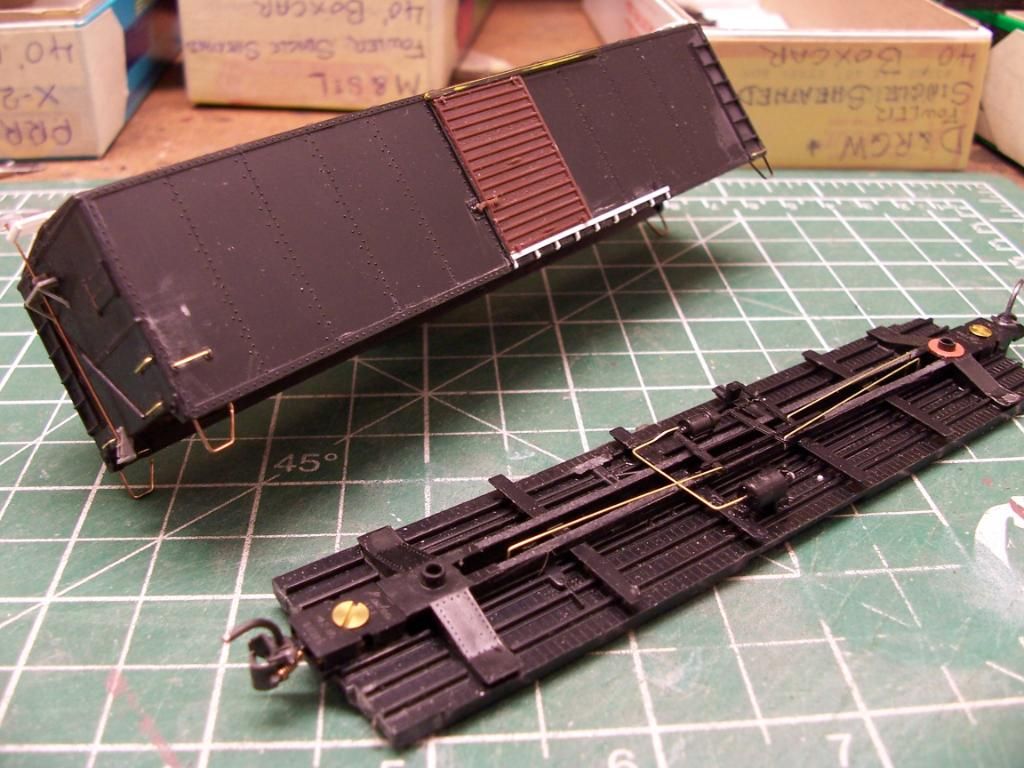

Looking at the pictures in you blog, I can see that you drilled through the coupler box cover, which is a tongue on the end of the floor. And then tapped the pin on the underframe piece for the screw.

Unless I am missing something this doesn’t eliminate the issue of the flat spring being mounted upside down. Also in order to get at the coupler one would need to separate the underframe from the floor. Is that correct?

Note that I’m not being critical. I’m just trying to understand the assembly. Did you consider cutting the tongue away from the floor so that you could end up with a removeable cover, or is there some consideration that I’m missing?

ありがとうございました

Maxman, thank you for reading my blog post.

The coupler is assumed to use a whisker type. The flat spring type does not work well.

The reason for not separating the coupler lid from the underfloor is because there is a gap of about 0.5 mm (0.020 inch) between the lid and the rotating shaft. Therefore, since the screw tends to loosen, leave an incomplete thread by tapping. Furthermore, in order to hold the lid in a stable manner, it remains integral with the underfloor. Look at the following cross section.

I don’t recall ever having problems with the couplers on Details West boxcars, nor with the clip-on covers from Athearn.

For Accurail, I simply drill through the peg on the box lid, then counter-bore to partially recess the screw head…

Train Miniature cars had a press-on lid as an integral part of the underframe, but it was easy enough to remove both the lid and the box, which was cast as part of the underbody, then replace them with screwed-on Kadees in Kadee boxes…

Tichy press-in covers are easily drilled to removed the peg, and like Accurail, can be partially counter-bored to recess the screwhead…

Wayne

I sold them along with my Athearn BB and most MDCs when I switched my shortline switching layout over to more high fidelity stuff. But they all performed well and were rock solid and free rolling.

I don’t recall them having droopy couplers, but I used to use the 2 piece Accurail Accumate knuckle couplers typically found in Atlas products in all of my cars of that type, and not Kadees, and those coupler shanks seemed a bit thicker.

I still have two a UP and Thomasville fruniture industries.

Received the DW car painted for Boise Cascade yesterday. Three undecorated due today. Very nice model, definite step up in quality from BB Athearn and Roundhouse! Interesting that DW provides a set of 8 ladders colored for Boise Cascade and another 8 unpainted white ladders. Wow, those modeler applied ladders are very thin and flimsy… I don’t have staging on my small layout and cars get handled a lot so I’m a bit concerned about breakage. Is there a wire upgrade for the ladders and is it worth the cost for reducing breakage?

Looking forward to building these boxcars!

Hi Russel - you wouldn’t happen to be interested in selling the Thomasville Furniture Industries Boxcar?

Scott

Will have to think about it.