there’s no issue using a smaller gauge wire, it’s what the command station manual (pg 2-1) specifies “(22 AWG or heavier)”

Ignoring the rest of the sentence that I did not quote, why is it a bad idea? You have a fat wire that needs to go into a skinny hole. A Western Union splice between a 12 ga and 22 ga wire doesn’t sound like much fun to my arthritic hands and what happens is the smaller guage wire wraps around the larger guage wire, which doesn’t move much at all.

Choosing either of those techniques, or side to side soldering of pieces of wire, or suitcase type connectors, is there any difference electrically?

I think I’m glad I asked the question, but I’m sorry it morphed into what I didn’t think was a thing to generate these disputes.

Good news is that most of the posts gave me the answer. Better news is that iv solve the problem by modifications to a 9 screw terminal strip.

If anyone else has a similar problem I’ll explain what I did.

Mike

Hello All,

You should feel confident in asking questions on these forums.

You should not feel responsible for the negativity generated by others.

Unfortunately- -as with other aspects of modern life- -readers need to “filter out the noise” from the negative sources.

Yes, there are bad actors on these forums.

There are many more that truly want to help enlighten.

Over time you will come to recognize the sincere sources.

Personally, I don’t give credence to several participants in these forums in regards to their responses. And, I’m sure there are those that feel the same about me.

That being said…

Congratulations on finding a solution!

I too am a big fan of terminal strips (barrier blocks, etc.).

On my pike I am unable to run traditional bus wires.

From the NCE command station/booster a pair of 16 AWG wires run to a 12-pole terminal strip in the center of the pike.

The wires are tinned at the CS/B end. For the terminal strip ends I use spade connectors or tinned ends, depending on the receptacle.

Every other pole is ganged together with short sections of 22 AWG wire with spade connectors or tinned ends.

This gives 6-pairs from the booster to tap into while reducing the wire gauge from 16 to 22 AWG.

I have five (5) power districts total: four (4) protected by single NCE EB1circuit breakers, and an NCE AR10 (auto-reversing unit with a circuit breaker) used for the wye.

The circuit breakers tie into the terminal strip from the command station/booster “downstream” or “output” of the terminal strip.

Glad to hear you found a solution to your particular solution (see my signa

I also am a fan of terminal strips. I found these that have all the screws connected. I can connect one screw on each strip to the power, and branch off all the other screws from there. The top left screw on each strip is input power. All the other screws are output.

This is for some LEDs in my layout’s town.

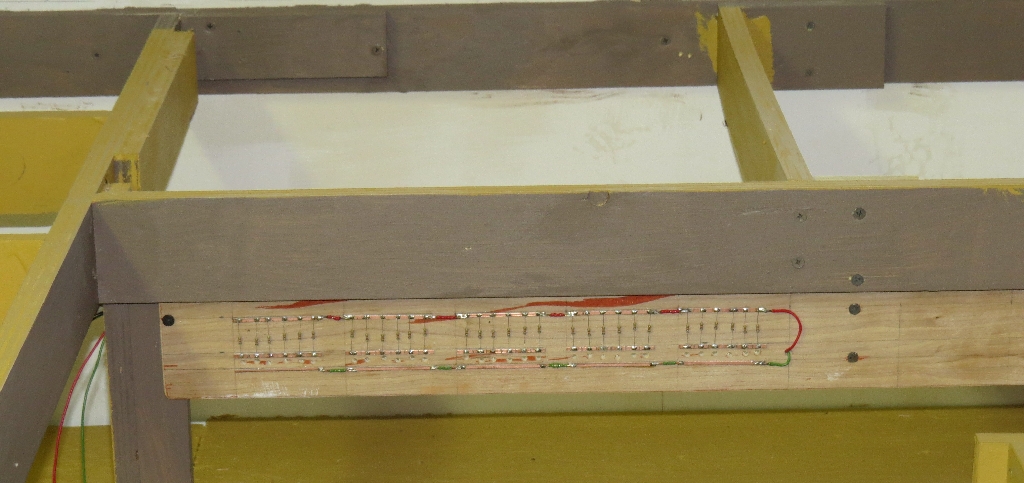

I did something similar with tie strips. I pre-placed the resistors so all I have to do is pull the wires through and solder them to the two lower strips.

The bus work is just inside the rim joist on cup hooks. They can be dropped down below the framework and feeders can be soldered from a chair in the isle.

Nice work!

I had already completed quite a bit of the wiring for my layout by crawling under the table and working over my head – not good!

Lion posted a picture of his wiring that was all right behind the fascia. That’s when I changed how I was doing things, and it was the best thing I did. Just like you, I can now sit in a chair and do all the wiring connections.

Terminal barrier strips and terminal blocks/bus bars are very handy if you need to change wiring. Or if you need to be able to break your layout benchwork into sections.

Continuous bus wires have the advantage of no risk of bad connectors but bus wiring using sections of wire screwed to connector strips have a number of advantages over continuous wiring.

It never occurred to me to plumb terminal strips in the middle of 12ga feeders, or mount them to hang on cuphooks for easy access. It was worth all the consternation just for these insights!

I have a MRC Prodigy Advance² Control Station and it uses a green Phoenix 1757035 Pluggable Terminal Block, wire size #12 AWG to #24AWG.

I use #18AWG stranded wire between the controller and my power buss.

Mel

My Model Railroad

http://melvineperry.blogspot.com/

Bakersfield, California

Turned 84 in July, aging is definitely not for wimps.

LOL!

Well, wrap me in dough and call me a Twinkie.