I assume you are talking about a plastic ‘H-type’ joint cover?

They are too proud (not flush enough), and usually to short in width to mask the 1"-2" wide joint I wish to hide.

I assume you are talking about a plastic ‘H-type’ joint cover?

They are too proud (not flush enough), and usually to short in width to mask the 1"-2" wide joint I wish to hide.

I was real careful such that my vertical wall seams are almost perfectly mated.

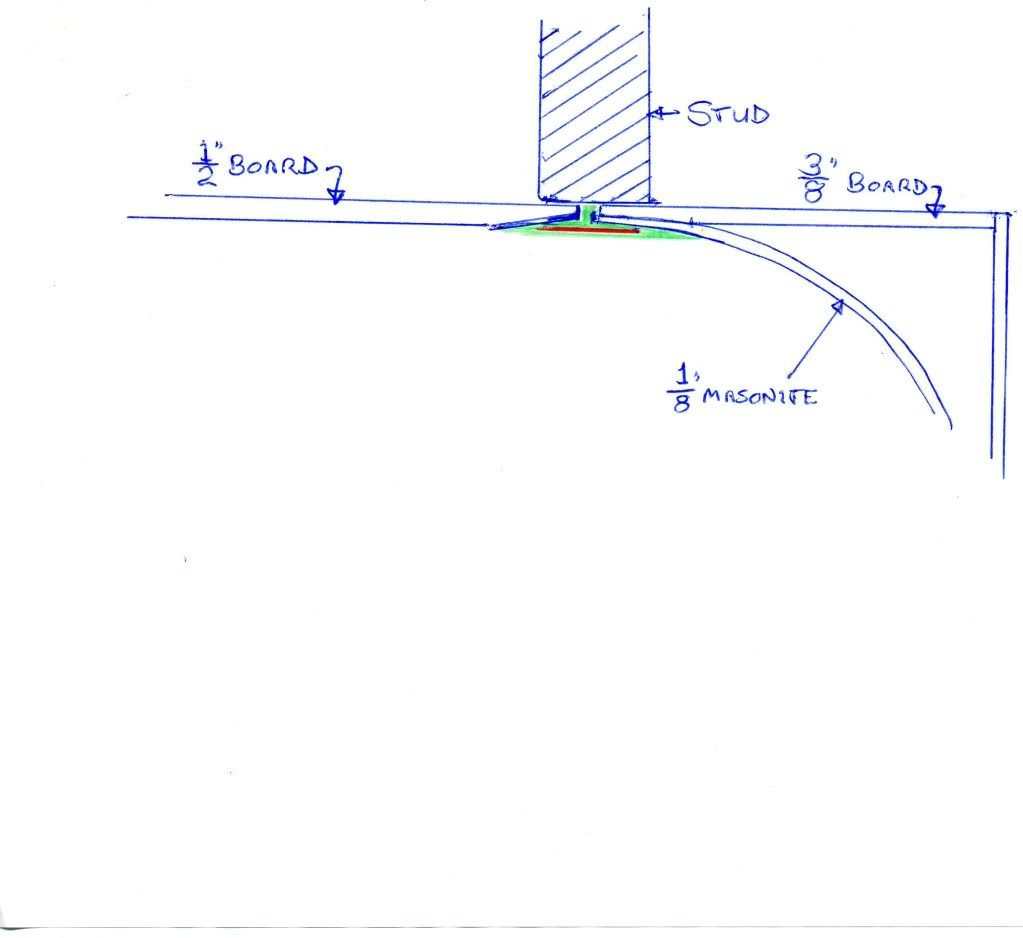

My ceiling to wall joints are an unusual angle so molding will probably not be a viable solution. But here again I cut very good fit that can likely just be caulked in.

Wondering what adhesives (tape and caulk) are most suitable/compatible with Masonite??

BTW, I intend to glue a double layer of this tempered hardboard (Masonite) together to build the roadbed for my helix.

I’d think that just about any tape would stick to Masonite, but how long it would hold is a different concern. While caulk does stick to things, I wouldn’t consider it to be a very good adhesive, particularly for construction uses. Better choices would be yellow carpenter’s glue, or LePage’s PL Premium - I used the latter to splice my upper level fascia together into that 50’ long section. C-clamps held things together until the PL cured. Another good choice would be contact cement, but be sure to follow the instructions on the can.

Many people mistake the “tempered” adjective to mean that that variety of Masonite is more flexible, but my local lumberyard has assured me that the term refers only to the hardness of the finished surface. It’s no more or less flexible than the regular stuff.

I use it on the tops of my work benches, but won’t waste money on it for layout fascia or coved corners on the backdrop.

Wayne

Use spackle, the pink stuff that turns white when dry.

The only problem with putting tape over the joints with the staples is now you will have the opposite problem - the tape will stick out relative to the rest of the surface. It works with drywall tape because tehn you cover it with mud and feather it out so there isn’t a bump just at the joint, it gradually bulges such that (with a good job) you don’t realize it. If the visible parts will be covered with printed backdrops eventually, I don’t know that I’d worry about it, especially if the full panel width gaps are pretty tight. The printed backdrops will cover any divots where the staples are. I’m not sure how well drywall mud will stick to masonite, compared to actual drywall, the masonite is very smooth. Perhaps if you rough up the masonite first. But not to go nuts and tape the joint then attempt to feather it all in, more along the lines of using some spackle like filling a hole in a wall left after removing a picture. Again, if it will end up covered by something anyway, it won’t have to be perfect.

–Randy

When I did the coved corners on my backdrop, I use sandpaper to scuff-up the Masonite on the face of the vertical edges, and the drywall mud sticks to it like…never mind. [:-^]

It’s been in place since the layout room was built, about 25 years, I’d guess, and no cracks or bulges whatsoever.

Randy’s right, no need to be concerned if you’re later going to cover it anyway.

Wayne

BTW, untreated masonite warps badly with humidity swings. For those who are expecting a smooth finish using masonite in an unconditioned space, the first humid summer will be an experience.

I have a stack of it (two full sheets cut into strips 4 feet long, less the 2 pieces I had installed on the old layout) standing in my unconditioned basement (it’s finished, and has heat, but that just makes the low humidity in winter even worse - in summer with no dehumidifier it’s rather damp) for almost 4 years now, and other than being a little bowed from standing on edge, it’s not in the least bit warped.

–Randy

I think since its unattached and resting it has unrestricted freedom to move with the changes in humidity.

When its attached to the walls like a backdrop or sheething, the humidity caused mine to expand and contract differently than the substance it was attached to. Once I removed my untreated hardboard and primed it on both sides and all 4 edges, I was able to reinstall it without gaps and it never warped.

Per this spec sheet:

http://www.justtimberandpanels.info/Brochures%20in%20pdf/Masonite%20Standard_PDS.pdf

The humity expansion is 0.25% from 50 to 90% relative humidity. So an 8 foot long piece will expand by .24" if the humity goes from 50 to 90%. Not a whole lot.

–Randy

I have 1/4’’ wood paneling in My finished garage and use Vinyl Wall panel connectors. Looks a lot better than any other thing that has been mentioned aside from Dave H, this I believe is what He meant: Comes in different colors or paint Your color.

Take Care! [:D]

Frank

I suspect that I am going to try spackle. Mostly because I want the fascia to be removable and respackling is not as much of a pain as some of the other suggestions, which, I might add, were all good.

It probably makes a difference how many attach points are used. I went with untreated masonite attached every 16 inches to 1 x pine and got waves in between attachment points during the summers. Maybe if I screwed it down more frequently that would’ve probably helped it from buckling away.

Wow, Randy I wish you hadn’t posted that one…ha…ha

1/4" may not seem like much, but the humidity change is just about what we get in FL, and I have very carefully butted up my joints doing this low humidity ‘winter weather’ here in Florida.

I had (have) planned on giving the whole surface two good coats of an oil based paint (first Kiltz, then exterior grade), to help stabilize it. But I was not going (did not) coat the backside that is against the considerable insulation job I did.

Here are a few photos,…

Pretty good seaming if I say so myself. I figured I could ‘caulk’ some of these with a flexible type cauking that would resist getting hard and brittle, and subsequently cracking?

But then look at these close-up photos of some of the ‘divots’ that the stapling created, both proud ones and craters…

That was the circumstance under which my masonite buckled. This was in a basement in the Midwest where there may be more difference in humidity swings between winter and summer depending upon if the polar or tropical air masses are prevailing. I assume FL is fairly humid year round.

I also noticed you have an air conditioner, which dehumidifies the air and can atleast keep the inside a more consistant level.

You may be fine.

You people may not know it but there are different spects for masonite. The stuff I used back east could be used as underlayment, the stuff on the west coast is a no go. You will not have proublems with butted seams with masonite if you do the butt mid board like my 1x4 framed modules. Also if you can get a comercial carpet stapler, use that for attaching the masonite instead of screws, works great.

Maybe crazy, but I’m thinking large-head dent hammer could even out the staples and divots that stand proud of the board, making them all level with the surface or slightly depressed.

–Randy

That’s the first thing I thought of. Only possible issue with dry wall mud is any surface that flexes it would crack and chip away.

Riogrande…I have a 1/8" hardboard backdrop and it definitely flexes as the seasons change. I assume that the 1/4" will also flex.

Not near as humid in the winter (northern FL) as it is in the summer (very humid)

It was not intended that the AC unit would be running often enough to ‘maintain’ a house like enviroment,…but certainly while I was out there playng with trains.

I did a good job of insulating the shed, and foruntunetly I have the whole shed under the carport. That reduces the solar gain SUBSTANTIALLY.