I don’t have a super small set of them, but what you want is what’s called a JIS screwdriver. They are phillips type, but are made to the “Japanese industrial standard” Although they don’t LOOK much different, they don’t cam out when force is applied. They are useful for taking apart most any item that is made overseas.

I’m with Tom on this issue. The Wiha Tools are excellent. A bit pricy but the best screwdrivers I’ve ever owned. They also have nut drivers in both metric and SAE, great for model railroading.

Mel

Modeling the early to mid 1950s SP in HO scale since 1951

Look at Micro Mark’s site, Ken. They sell small tools, including those better precision nut drivers and many other better choices, for modelers in all hobbies and for crafts and small item repairs.

https://www.micromark.com/mini-hand-tools

I can’t be sure, but the nut driver sets, in both units, look a lot like the Wiha kind mentioned by several people.

The JIS screwdrivers are also known as crosspoint, different from a standard phillips head. And most JIS heads are shorter then the phillips. Might help to type crosspoint screwdriver on web and look at images. You will see a differant X pattern and also notice the shallow length of the tip

Hope this helps the explaining the differance in JIS vice Phillips

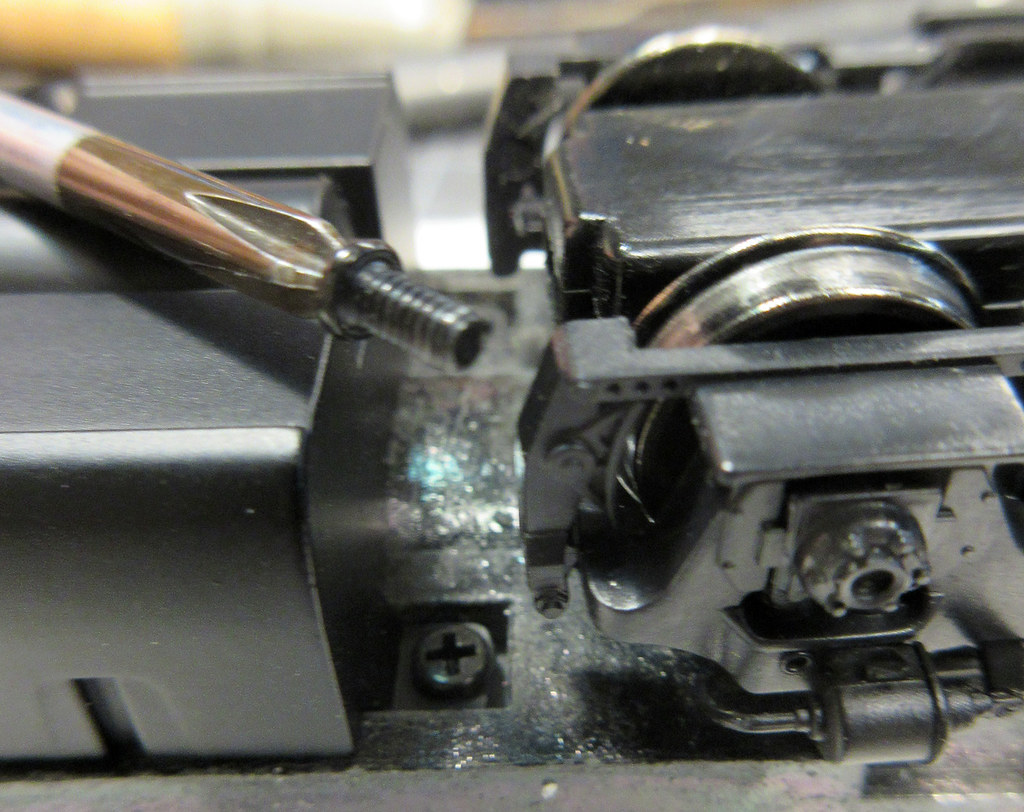

Curiosity got the better of me so I grabbed an identical BLI F7 to check the screw size.

BLI_F7_fuel2 by Edmund, on Flickr

BLI_F7_fuel2 by Edmund, on Flickr

A Wiha #0 x 50mm (261) driver fits the head nice and snug. No question of the fit. All four screws holding the fuel tank spun right out without any complaints or resistance.

BLI_F7_fuel by Edmund, on Flickr

BLI_F7_fuel by Edmund, on Flickr

Again, I still recommend the Wiha which I mentioned in my earlier post.

https://en.wikipedia.org/wiki/List_of_screw_drives

JIS B 1012 Heads are usually identifiable by a single dot or an “X” to one side of the cross slot.

Thank you all,

It will be good to hear from Ken after all this discussion [:-^]

Regards, Ed

Well thanks for all the tips and links folk’s!

7j43k I am a old wrech and used that trick many time. In this case it was a very bad indea! [sigh] BLI engine I am talking about had strange rubbing sound that sounded like drive train or fly wheel rubbing I knew about when I got it. For all most a year no strange rubbing sound. Few months ago sound was back. When I tried to get the fuel tank off I was tapping the screw driver with a set of needle nose’s. I will be danged, the pot metal chassis broke in half! [banghead]

Brent aka Batman. Wonder what the wife will think when she finds a BLI F7a in the frezzer Saturday. [:-^] Trying to get the motor out to be used in a driffrent project.

Rick I owe you a Root Beer Float. I will check at lowes.

Thanks again folks for all the links and help! [:D]

Ken

I have nothing new to add, but you can put my name on the list of people recommending WIHA brand miniature screwdrivers. They are great.

.

-Kevin

.

I hope I’m not repeating anything that was answered on this thread. If I did, I do apologize. I did not read it in its entirety. With that said I can tell you this.

Nothing is made here anymore. Neither screws or bits, you name it… Nothing mates anymore.

There was a time when there was only three four types of screws and three four types of drivers. Now there is about 60-70.

I have a hard time finding drivers that mate with the fasteners that I use in construction. When I do find that mate, it’s a crying shame the screws that are available are so full of pot metal they don’t even work, but they sure charge you a pretty penny for them.

This could be your problem. Whether it is or not it certainly is my problem.

Sometimes I have time to mate screws with drivers. When I do and I get all my Hardware in a group… I sure am a happy man.

Respectfully Track Fiddler

As a former auto mechanic, I used to remove small stubborn screws with a pair of side cutter pliers if the screw was not recessed. A small pair of pliers gets under the head grips the screw. And in some cases on a recessed screw, I would try by using a pair of minature side cutters and try to get into the area between the two pieces the screw was holding together and grip the screw with minimal damage. Of course there were times of drilling and tapping IF your drill bit was stronger than the fastener you were drilling.