I forget the brand name but,it looks like little rocks and it makes very good rip rap rocks around bridge abutments,shore lines and other areas.

Just remember to remove from the bag–not the box. [swg]

I forget the brand name but,it looks like little rocks and it makes very good rip rap rocks around bridge abutments,shore lines and other areas.

Just remember to remove from the bag–not the box. [swg]

My thoughts exactly, Larry.

If you’re using Woodland Scenics’ ballast and it’s floating, you’re not using enough wetting agent: the “wet” water needs to be of sufficient quantity to wet the ballast right down to the roadbed.

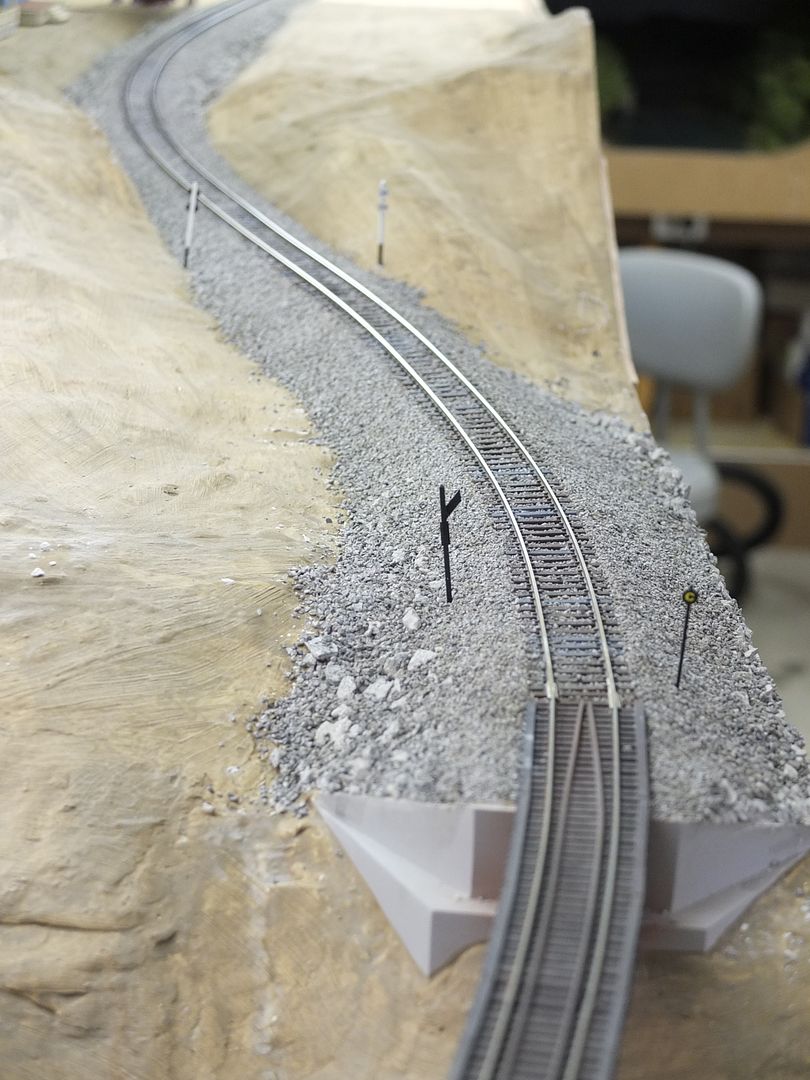

I used WS ballast on all of my original layout, but when I began work on the upper level, I used some ballast given to me by a friend. He bought several tons of it for his driveway (limestone screenings) then used various seives to obtain enough scale-sized stuff for his rather large layout. I’ve used-up most of what he gave me, and then bought a couple of bags of the same material from a local building supply place. It’s a slightly different colour, a condition often seen on the prototype when the ballast comes from a different quarry.

While there’s little chance of real rock floating on our layouts, the ballast still needs to be thoroughly wetted so that all of it will accept the diluted glue mixture, bonding it securely to the roadbed rather than simply forming a hardened crust on top.

I found the WS ballast easier to spread, as the real rock seems to interlock together (much like real ballast) enough that it reqires more brushwork to distribute it evenly along the right-of-way, but I can’t say that I favour one type over the other.

Wayne

Ah, the age old time v. money debate. I would suggest buying commercial ballast over homemade. There is a TON of variety of ballast and you can get quite a lot from a shaker bottle.

The amount of coverage you need varies it depends on how much you apply. I would always err on the side of putting a bit more since the ballast shifts.

Arm and Hammer brand works well, looks best if larger particles are sifted out (in my opinion), can be dropped on the bottom of the grade.

Keep in mind it is clay and may contain traces of iron. I used it on a layout and did not have any problems but kept the ballast off the track.

If memory serves, I recall they used to clean F100 (the plane) compressor / turbine blades by running crushed walnut shells through a running engine on the test pad.

Yes, that is it. The self clumping kind is much smaller and needs little or no sifting. LION does not glue ballast, for that makes a mess when you try to move a track. Gravity works for the BNSF and it also works on the Route of the LION.

Another option is sand blasting medium. Looin in a contractor’s supply company for the stuff, it comes in various colors and grades and is also very cheap, compares with the price of cat litter.

ROAR

Utah, Idaho, Oregon and California have provided gray sand ballast for my layout. Colors vary depending on the local source from brownish to nearly black.

I’ve encountered commercial play and tube sand, as well as paver base sand, that have also been gray.

There’s a fine line with the stuff. Too little wetting agent and it won’t glue properly, but too much and it washes out easily. Getting it just right seems to be challenge for a lot of modelers. You seem to get great results from it.

I recall from prior discussions that humidity can have an impact. I live in a dry climate where static wreaks havoc with Woodland Scenics ballast. While being brushed into place it can fly around and land where it’s least wanted, a problem I don’t have at all with real rock.

Cat litter, really!

Too much dust, mostly to big to use as ballast, yes it is cheap but after spending allot of money on your trains, buildings, scenery materials your going to cheap out and use a product that is used for a animals to defecate in. Give me a break.

Use a product that is made for the purpose

If there is an abrasive manufacturer near you, try asking them for any rejected material. I work at one, and have all the ballast I need, along with you-name-it minerals for steel mill, hopper cars, beach, earth, etc.

Mike

Of course care should be taken when introducing genuine abrasives to the layout as it needs to be kept away from locomotive and rolling stock bearings, gears, open frame motors, and other sensitive areas. Particularly if it is magnetic. Well secured ballast should not be a problem. Loose open loads could be a problem long term. Of course nearly anything can be abrasive - any powder. Crushed corn cobs are used these days to “sand blast” old brick buildings after all.

I have used finely sifted fireplace ash both for cinder ballast and as a weathering powder and was advised by one modeler that it might be introducing too much abrasive into the modeling area. Our 18th century ancestors used fireplace ash to polish silver!

The advantage of crushed walnut shells for reptile glass cages, I gather, is that it is NOT abrasive as stone is and thus does not mar the glass.

Dave Nelson

Dave,I agree the kitty litter is to big for ballast but,the kitty litter I mention is good for rip rap rock found around abutments,shore lines,dams ect.

There is no dust problem since you glue it down by using your favorite method…