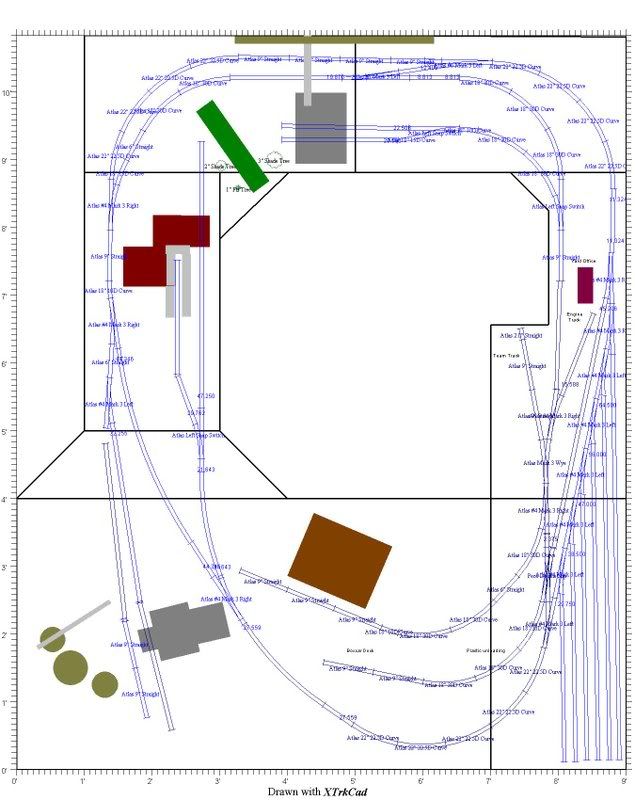

Here’s a triple post and a revised full layout plan.

Changes: Industry placing, track work, narrowed the duckunder

Any comments or advice?

Here’s a triple post and a revised full layout plan.

Changes: Industry placing, track work, narrowed the duckunder

Any comments or advice?

You may still have some challenges with reach from the operator pit for pretty much everything along the lower part of the layout - from your gravel spur to your yard tracks - benchwork is about 4 feet wide in this area.

I don’t see any staging track(s) ?

Your main track has only one passing siding

Trains has to be moving clockwise to drive into the yard. They come out of the yard driving counterclockwise. Are you planning to back trains out of the yard, back trains into the yard, or to run the engine around after moving out on the main or before moving in from the main ?

You still have only about 12" of space in front of the cupboards in the upper left hand corner - hopefully the doors and the person getting stuff from those cupboards once in a while are both pretty narrow, or you may experience trouble opening the doors and/or getting stuff from the cupboards.

Stein, temporarily relocated from N to MN, wondering what time zone my body is in now [:D]

Finally had some time to try to figure out XtrkCad, and to mess around with the plan.

Changed a few things.

Had the main come into the yard ladder, to make life a little easier. Did need a double slip switch, though.

Moved the engine track.

Condensed two tracks into one, in the bottom. Many industries share a track.

I’m sure there are other tweaks that could be made, but experience will tell where they need to be made.

I really like what you’ve done with my plan- yard layout is still a crippling weakness of mine. I think now I’ll turn that runaround in the top left corner into a staging. It’ll go under the layout and level out near the south edge of the operating pit. I’ll get a picture of that soon.

Would probably still need the runaround to service the gravel/cement unloader, unless trains would come out of the yard to make it a trailing point move. The yard should work better. If the plastic/boxcar track isn’t needed, could use a normal switch instead of a double-slip. One of the yard tracks could be designated as an interchange track, when the foreign road comes to pickup/deliver they would use that track, unless it all doesn’t fit.

Using the CAD is sometimes harder than just laying track. I tried using #6 switches for the first two in the ladder, then #4 the rest of the way (larger radius “S” curves, better reliability). Using flextrack, the extra curves to get to the straight yard tracks isn’t a problem. The CAD didn’t like it.

The track past the gravel loadout on the top could be a foreign line. Have it start dropping down, could go behind/under the scrapyard. They could switch out the gravel loadout, then disappear with their other interchange traffic. The UP and ICE interchange jobs in Janesville run with 4-axle power, the ICE drops away.

Many other options are available. Flop down some track and run trains, see what works, what doesn’t, and what you actually like to do. DCC makes it a bit easier, can have multiple trains running in this small space.

The downside to just playing with it is that I’m going to be stuck in the planning stage for some time, it seems. I think I forgot to mention, though, that all my local locos are 4 axle while my only foreign interchange loco is a 6 axle.