Go look at the thread on Mallard speed records, there are pictures and more discussion.

See Doug Self’s site for the low-down on all the motor locomotives.

19 1001 has four 90-degree V-2 motors, two each side, each driving one independent axle. Gottwaldt’s book has some information Self doesn’t. This was imho a better approach in principle to the problems with high-speed drive than Besler’s, but YMMV.

W-1 was the Besler locomotive – not a 4-8-4 but a 4-2’2’2’2-4. As mentioned, one of the motors was built and tested, and I’m trying to see what information on the project has survived in Besler’s papers. Not mentioned so far: the boiler for this locomotive was built and finished, but was never actually used (diesels giving a better perception of what B&O needed by 1941).

The French approach has some interesting details, notably the attempt at conjugating the engines to make their rather amazing high-speed-slip proclivity less… I suspect the conjugated-throttles approach would not have worked completely in practice, but that’s because I’ve modeled the situation in a different context.

Have fun over on Self’s site – he has done tthe work for us all.

RME

I have had the 4-10-4 wheel arrangement stuck in my head for a long time. I was thinking of 72" drivers, 300psi, and a coal burning Gas Producing firebox for more efficient burning of the coal. Coupled with light weight rods and roller bearings would at least in my mind a cool locomotive. Also one of my favorite locomotive wheel arrangement is the 2-10-2. I was thinking take the 1920’s loco and update it to a modern one. Cast integral engine bed, 68" BOX-POX drivers, light weight rods and roller bearings. At least 250psi boiler pressure and a big boiler to power it. This one to would have a coal burning Gas Producer firebox. A more powerful and faster locomotive, with the 68" drivers it helps against dynamic augment and it should go at least 60 mph.

Welcome aboard Basta Tim, don’t recall seeing you here before.

And I LIKE the way you think!

Welcome!

(Interesting that this appears to be the original thread that spawned the others-and refuses to die.)

Thank you I am mostly a reader of the forums and not a poster.

Just wanted to add my two cents.

No problem! This is probably the best place to put this. There is just a complex story associated with this thread.

My comments-

Santa Fe had 2-10-4s with 74" drivers. At the speeds that this would be allowed to run, (<80MPH) a four wheel front truck wouldn’t be necessary. Also, where do you think this would have run? Fixed wheelbase on this would be very long, restricting use. I offer this as constructive criticism to help you improve your design.

I trust we can change that – dramatically!

I’d like to apologize, I was much more blunt last night than I intended.

I encourage you to post your ideas and thoughts, because they are good ones. I’ve learned a lot from others here asking questions to try to improve my designs (such as an extreme-drag-freight 2-8-10-6 of questionable usefulness), and was trying to help you. I hope I haven’t scared you off.

I had a similar idea for a 4-10-4 locomotive, but a 4 cylinder design with the cranks set at 120 degrees for smoother running and better balancing. Perhaps even a compound design? Would probably take some work to make it flexible enough to run at decent speeds and make it around curves, though. Blind drivers and lateral motion devices might make it work, though.

I was more a fan of oil firing, though. It seems to me it would be easier to implement one person operation with oil rather than coal firing.

The 2-10-2 is a locomotive that has more space for improvement. With the introduction of the Super Power locomotives the Santa Fe fell out of favor. I was thinking of Cast intergral frame and cylinders and the delta trailing truck. Big boiler and firebox and with a boiler pressure of 240 to 260psi. it will have 68" BOX-POX drivers and roller bearings on all axles and rods. With the 68" drivers and the roller bearings, this locomotive will have a faster top speed and better counter balancing. having 68" drivers will also help with the dynamic augment problems that plagued this type. The firebox will be a coal burning gas producer to combat the efficiency problems inherited with steam locomotives.

What say people on this forum about the effectiveness of “gas producer” coal combustion?

I read over David Wardale’s Red Devil and Other Tales of the Age of Steam, and the main motivation for the GPCS (gas producer combustion system) is to reduce the carry over of carbon particles (“char” and “sparks” and “cinders”) in a coal-burning lump-coal grate-fired locomotive. The idea is that if you can reduce the primary air in the coal bed, you will reduce the tendency of the fire to lift. With reduced primary air and a thick enough bed, you will get the chemical reaction to make combustible gas above the firebed, which will burn in contact with secondary air, introduced through an open fire door or through ports through the firebox.

Red Devil reads to me like a treatise in frustration of Wardale trying to get the GPCS to work up to its promise. By the end of the book, he is resigned to “pulverized coal” as being the only answer to getting complete combustion of coal fuel. But with PC (pulverized coal), you have the handling problems and explosion risk of handling PC on a locomotive, and not only that, all of the fly ash is sent up the stack. With lump-coal-on-grate, you stand a chance of at least keeping half the ash out of the atmosphere and into the ashpan.

Maybe burning coal to do anything is a lost cause, given the new EPA regs to try to take coal-fired power plants out of service. But there are a variety of combustion system besides PC that people have tried and indeed use, and GPCS is only one of them.

The one I find most intriguing is some form of “slag tap” combustion. The idea is that instead of trying to avoid the curse of clinker formation, you embrace it as a way o

Most of you may already know this, If so, sorry for the rant… If you watch coal burn, naturally aspirated, and correctly vented, you’ll see a nice blue flame above it. This is not often seen on a steam engine unless its about to get its fire dumped. This Blue is the actually the oxygen burning up the coal AND coal gasses. The more modern steam engines use Steam, in the smoke box, to help create a “draft” in the firebox. This is why they do not need a tall smoke stack like old wood burners do. This extra “draft” makes large coal burn faster, but much less efficiently. Smaller chunks, closer together can help as it slows down combustion and still makes heat. In Western US, the Bituminous coal is already filthy and dusty and actually seems to burn up better with the extra draft . Starting a Steam engine with Anthracite and making that firebox super efficient would take at least 1 hour, then the calories it takes to boil water would make it necessary to add draft. Better draft control with emissions testing on board may help this “coal gas” and particulate “situation” . Firebox design hasnt been NOT really been gone into in half a Centry or so. Maybe a recirc Smoke gas chamber would be of interest. A guy named Paquin got a patent for this design for wood stoves ( late 70’s? early 80’s? )and Its been used in coal burning as well since. As most of us know, Coal is the Most powerful fuel on earth ( aside from nuclear) IT has the most calories per ton of Any fuel around 22.4 Million BTU per short ton. Burning it more efficiently in a steam engine should be looked into. That said, this current EPA is shutting down coal plants everywhere, One would think this could be overcome with some science and DESIRE.

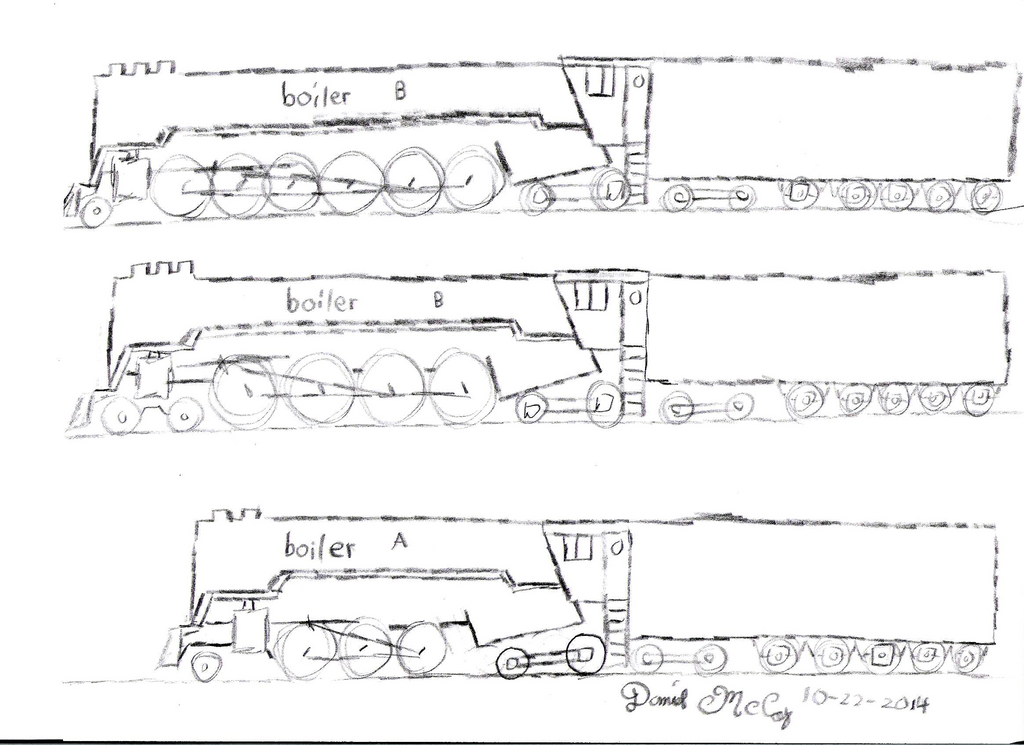

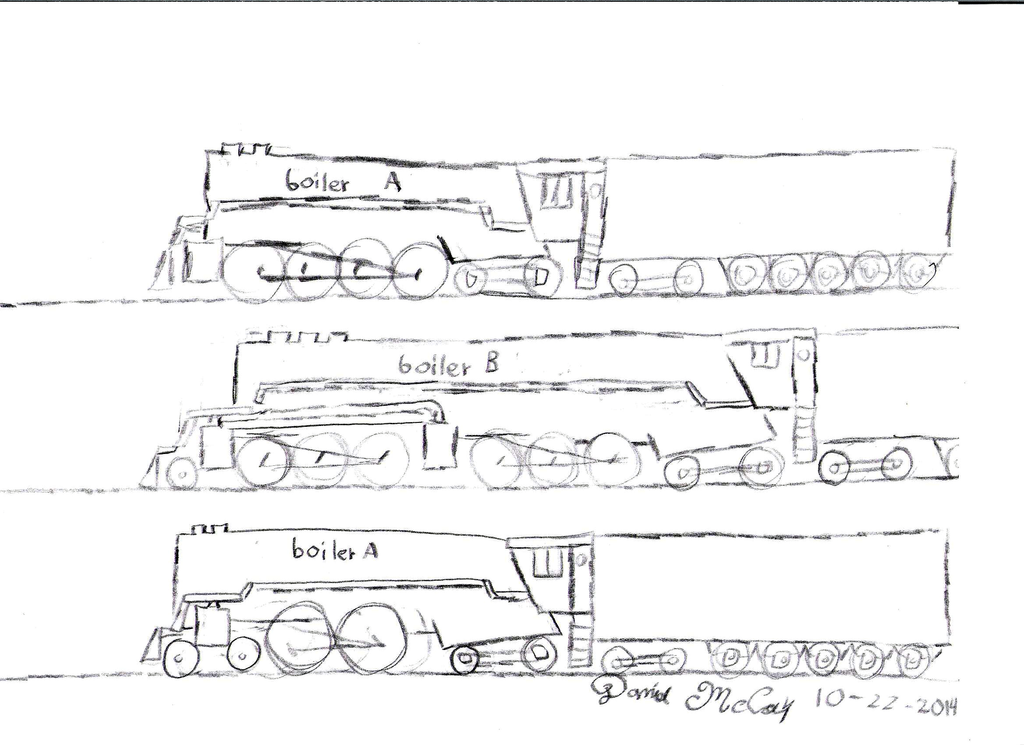

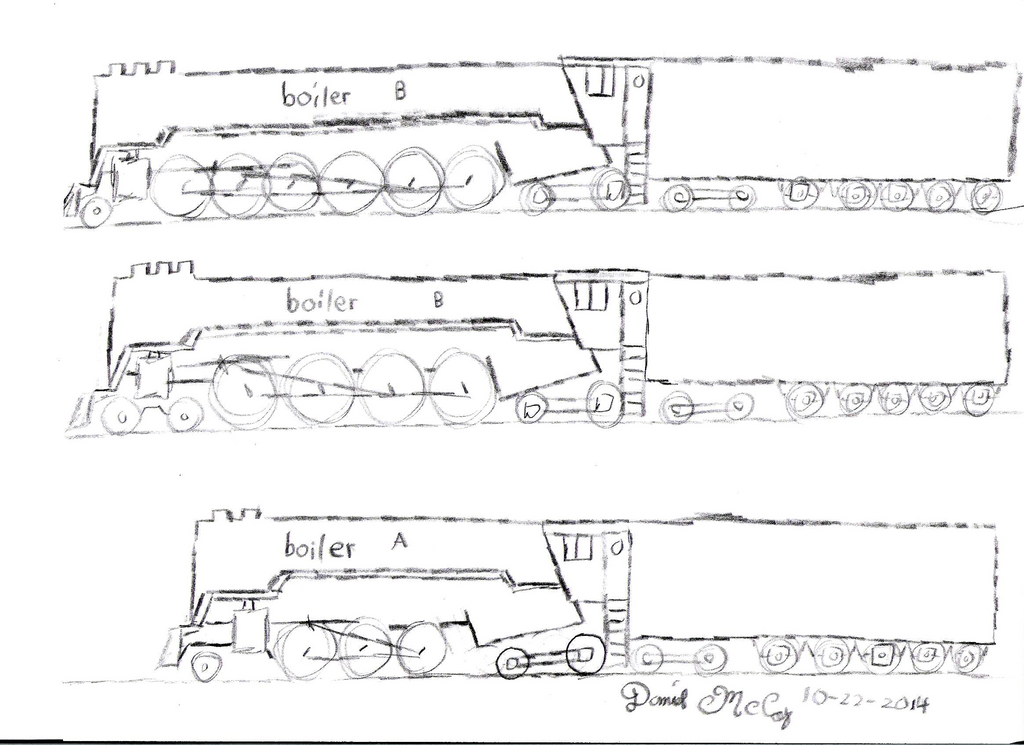

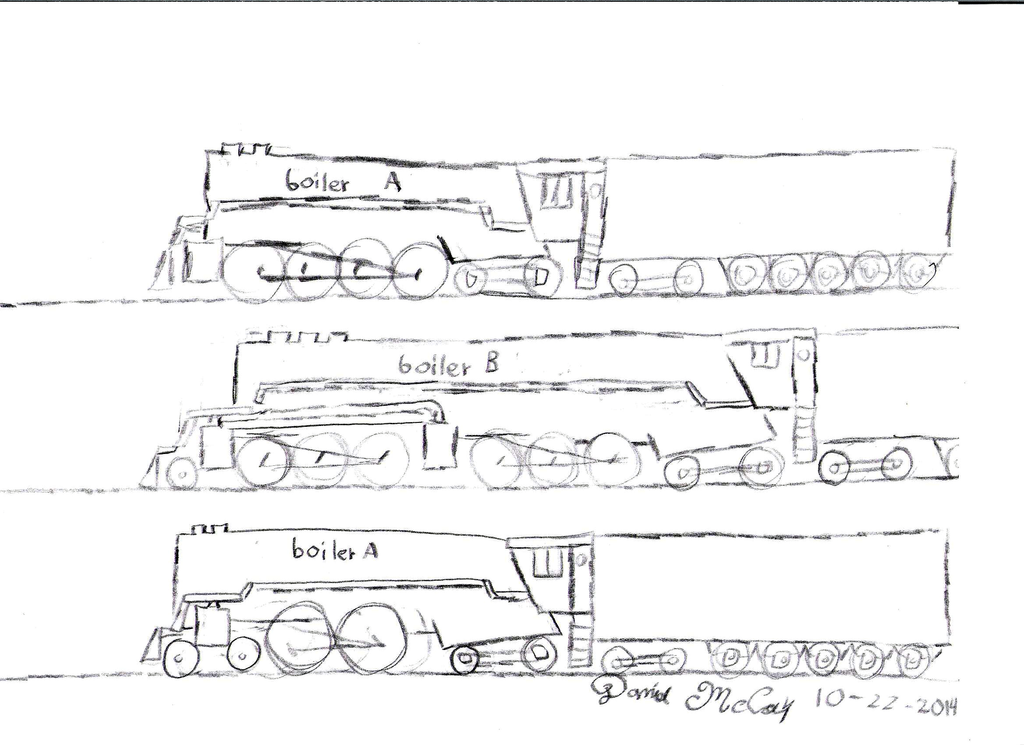

Here are some locomotive consepts.