I usually solder the joints on turnouts. I use code 70, hand laid turnouts. Once they’re ballasted in, there’s no trying to move or save them anyway, so I solder for conductivity.

I usually solder the joints on turnouts. I use code 70, hand laid turnouts. Once they’re ballasted in, there’s no trying to move or save them anyway, so I solder for conductivity. Dan

Nearly all my turnout joiners are soldered as well. I have a few unsoldered joints on some random places for “expansion” but any time I check them (over the past 26 years) the gap, about .020, has remained the same or close to it.

When I’ve decided to remove a turnout I clip or use a cutoff wheel to cut the rail just downstream of the soldered joiner, remove the turnout and then unsolder the joint and clean up the remaining rail.

Chances are if I’m removing a turnout for whatever reason it’s going in the scrap bin anyway.

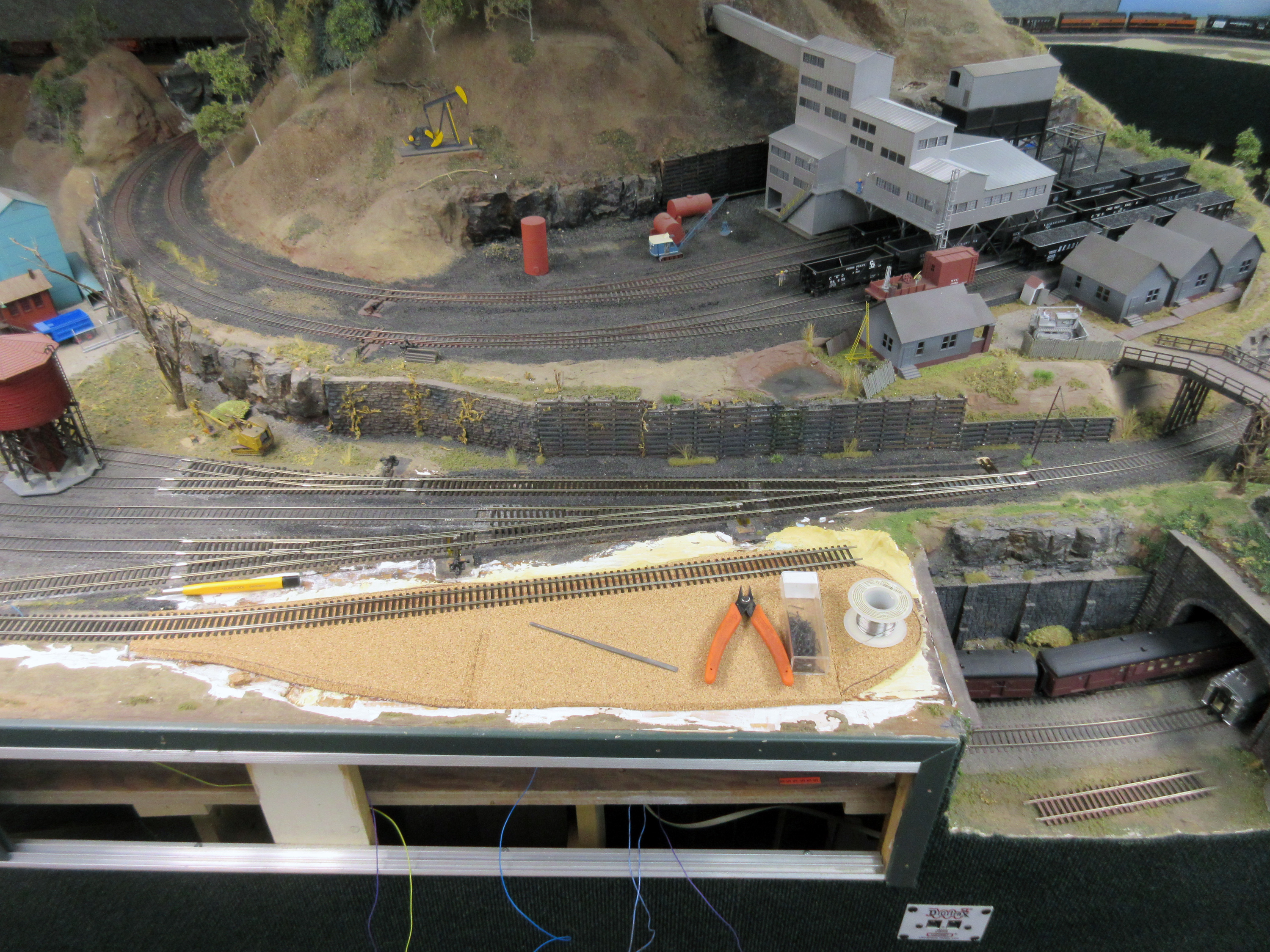

I recently rearranged this yard and the old turnouts were scrapped.

West end yard-a by Edmund, on Flickr

West end yard-a by Edmund, on Flickr

West end yard-painted by Edmund, on Flickr

West end yard-painted by Edmund, on Flickr

Good Luck, Ed

I don’t solder my turnouts either. (I don’t solder anything on my layout.) I’m no good at soldering anyway. My layout area is such that I need the track to be able to move a little as it is in an unheated garage. Have never had a major problem with track kinking with temparture change. Being in a dry climate helps too.

Power feeds are mostly custom made terminal joiners (bought via eBay) with specific wire colors for tracing purposes. There are a few commercial ones.

My oldest son repairs his own guitars (has a band), and had an extra one of these so now I have one too!

For Atlas code 83 track, I use their N scale code 80 joiners. They are a lot smaller than their HO 83/100 joiners. File the end of the rails to chamfer the corners to be able to slide them on, then the code 80 joiners fit snuggly.

Many HO scale joiners are too big and clunky looking. Probably made for sectional track at its root, where no soldering is involved.

both. Use the joiners and then solder the spaces between the rails

I solder and run feeder wires to every other joint. Using 3 foot HO flex track creates a 6 foot section of track wired by the feeders. No section of track relies on the rail joiners to carry the current.

You can solder and run feeders to every joint if you like but to me that is like wearing a belt and suspenders.

:max_bytes(150000):strip_icc()/GettyImages-160869327-57f871694a4a4d69b2503f311cf31fbc.jpg)