Only if so equipped. Few were.

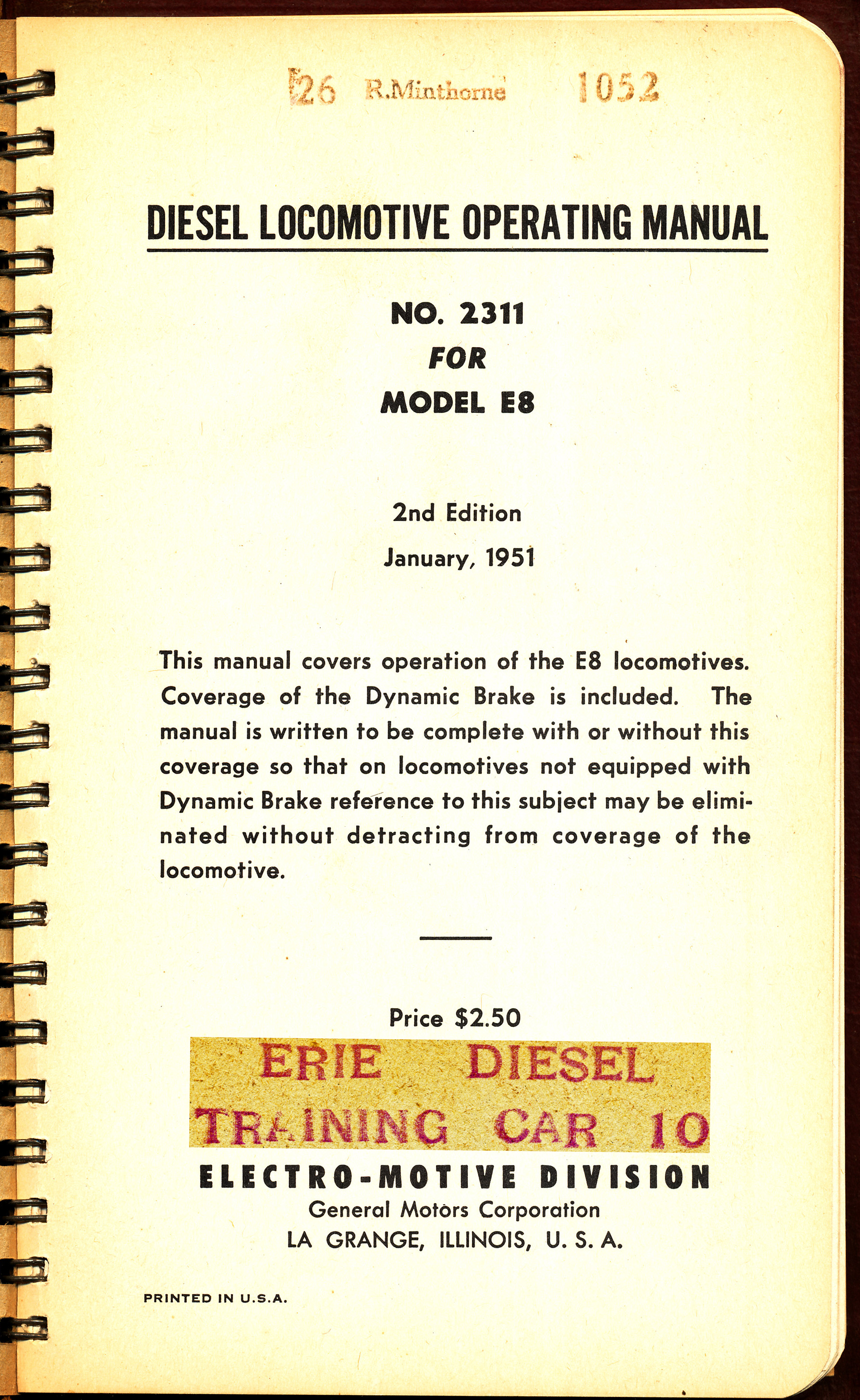

Both the railroads and the locomotive builders invested quite a bit toward instruction of engineers, firemen and mechanics to insure proficient operation of their new investment. Many larger railroads used instruction cars that would travel to division points or other areas where involved employees were centered.

IC (l to r) diesel instruction car and air brake iunstruction car at Central Station, Chicago, IL on June 13, 1968 by Marty Bernard, on Flickr

IC (l to r) diesel instruction car and air brake iunstruction car at Central Station, Chicago, IL on June 13, 1968 by Marty Bernard, on Flickr

Thomas Underwood Coll B&O755 by John W. Barriger III National Railroad Library, on Flickr

Thomas Underwood Coll B&O755 by John W. Barriger III National Railroad Library, on Flickr

One of my E8 instruction books is stamped ‘ERIE Diesel Training car 10’

Erie_EMD-cover by Edmund, on Flickr

Erie_EMD-cover by Edmund, on Flickr

I also have several ‘How to deal with breakdowns on the road’ booklets published by the locomotive builders that the enginemen could carry in their grip.

EMD invested heavily into training.

Click the above image to be taken to the Flickr Album.

I lived near the NYC’s Collinwood (Ohio) shops and there was a permanent training facility here for anyone involved in operating or maintaining diesel locomotives.

Regards, Ed

A few years ago someone posted an old video on the forum about the UP Big Boys. They interviewed about ten former BB engineers, and most of them said they preferred diesels, and only one said he missed steam.

This film from the Canadian Film Board is worth a look. Several railroaders and even some passengers are asked about the passage of steam.

Enjoy, Ed

C&O had “mountain” Geeps and “flatland” Geeps - the flatlanders didn’t have dynamics.

B&O ordered some of their 1st generation units for designated helper service - as such I believe they were geared for a maximum of 50 MPH where as the normal freight gearing was for 65 MPH.

At some point in time it was decided that the ‘low speed’ engines were more trouble than their additional helper tonnage was worth and all were given standard freight gearing.

The usual problem with “low speed” designed helper engines is that the job doesn’t end when the train has been pushed up the mountain. The helper then has to come back down, occupying track capacity while doing so, and if that entails a problem like the Erie 0-8-8-0s, with low-speed augment and nosing so bad they needed costly Flaman speed recorders to detect even slight overspeed… then your operation may need rework.

Utah Rails had a cautionary tale of early dieselization, where switchers were used as helpers and equipped with dynamic brakes to reduce shoe wear on descents. I believe the poor ride characteristics of switcher trucks sank the plan…

In the territory B&O was using the first generation diesel helpers - track speed was 45 MPH for passenger or less. In that territory, diesel helpers restricted to 50 MPH were not an impediment. The problem with the 50 MPH helpers was it kept them from being used in other services as the railroad learned about the overall utility of road diesels in every form of service, as opposed to the specialty uses required of steam locomotives.

As recounted in posts in Classic Trains threads, I learned to operate Third Avenue Transit foot-operated, combination deadman’s pedal, foot-release-brake-right-front-door-opening foot-pedal streetcars on The Bronx’s Bailey Avenue Line, age 15-16 1947-1948,. But I had no problem in transitioning to regular EMD GP-7 controls on the Boston & Maine’s Portsmouth, NH - Somerville Yard freight, 1052-1953, and to running a 4-8-0 steam light-engine move, Pretoria “Engine Shed.” 1986. Lots of time running streetcars, Third Avenue, regular safety cars, and plain straight-air cars, at the Shore Line Trolley Museum. And an IRT Low-V subway train on the “6” Pelham Bay Line once. I could handle a Jerusalem Light Rail train if asked.

Making smooth, safe, and accurate stops, espcially in wet weather, is the real art that must be learned, and it can be transferred to different rasilway types.

That’s why you carried a brick in your big lunch box…

Saying they should have hired new engineers off the street to train them to run diesels is like saying a veteran truck driver used to handling an eighteen wheeler with all it’s gears and such wouldn’t be able to learn how to drive a car with automatic transmission. ![]()

Jim Boyd, former editor of RMC, worked for EMD going out with new diesels in the 1960s and riding along on the first trips to answer any questions and find any bugs in the diesels. He noted the only big change from steam to diesel for an engineer was the fact that the ‘power curve’ as it’s called was different. A steam engine gradually worked up to full power, so an engineer starting a long train put the throttle up to full power right at the start. A diesel has it’s power right at the start, so if you put a consist of diesels into Run 8, you could pull out the draft gear of a car due to taking up the slack so fast.

'Early EMD diesels had what enginemen called kick start, with almost field-coil current applied to the DC generator, but this was modified early on. My Bacholer’s thesis for my S. B. degree at MIT (1953) was on diesel lolcomotive load-pregular control. On most GP-7s,including the B&M’s, t5he engineer had the choice of kick-start for use as a switcher or peddler freightgp-7 with lots od switching or passenger start with reduced generator field current until full run-eight rotational sp;ped was reached. With my redesign, asa student erngineer ast EMD summer 1952, onlynone mode, the fielf current of the generator was adjusted ciontinually with one simple resistor inb the circuit, after the throttle was moved directly from idle to run, so that half the available power at any point was used to bring the diesels RPM up to the run-eight setting and half to move (accelerate) the train. B&M GP-7 1567 and 1568, with a dslightly different scheme, were then used on a Boston - :Portsmith (NH) round-trip, up on passenger, back on freight to Sommerville yard (with a frequent side-trip to the Nlorth Station throat for me to pick-up my Raleigh and go back to a late sleep at ther MIT Old-Senior-House Dorm). This systen was applied to the GP-9 and some subseqent models, to be made obsolete by AC generators,and then the all-AC drive-train.

Most railroads ordered dynamic brakes the holdouts that refused were the flat land running railroads like the MP IC and NYC being the biggest ones. But even the NYC started getting them why they realized that even without steep grades dynamics helped with train handling and lowered maintenance costs. You’re not burning up your brake shoes when slowing down with dynamics and it’s easier to accelerate out of a slow order as you’re not waiting for methe brakes to release all the way down the train.

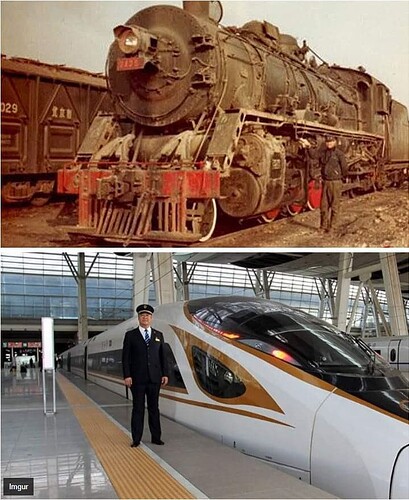

The start of his career, and the end of his career.

Wow! That’s a lot of change. Good for him!

Look at the locomotives corresponding to the beginning and end of Daniel Willard’s tenure on the B&O

Look at the locomotives corresponding to the beginning and end of Daniel Willard’s tenure on the B&O

My Grandfather was born in 1892 and died at age 98. Flying developed from the impossible, to possible but very dangerous, to commonplace for the elite, to commonplace for all. to putting Man on the Moon and returning them safely to the Earth. After my Father retired in 1972, he and my Grandfather flew from Maryland to Florida and return for a vacation.

My Grandfather also worked with Daniel Willard.

Most of the midwest roads didn’t have dynamics. Some started ordering them around the time EMD’s dash two line came out.

Even the Milwaukee with mountainous territory didn’t specify dynamics on some orders.

While dynamics would save on some items, I don’t think it allows accelerating that much better out of slows in most cases.

Before the modern AC locomotives, theres a required 10 second pause going in and out of dynos. Dynos are going to bunch the slack and you can’t just rip on them unless you want to rip the train apart.

Besides, back then they power braked, keeping the slack stretched out. It definitely used more fuel but made it easier to control slack.

Jeff

Adding dynamic braking added to the purchase price and added to the maintenance costs. The latter much more in the days of electromagnetic relays; all of whichbev3entually wore to the point where replacemebnt was necessary.

The steam engineer crossing over to diesel had to learn not to take the slack out to start freight trains. He had to learn what I am sure were a Matterhorn of electrical basics, and specifics about certain repairs out on the road to keep the train moving.

I had a friend years ago who was an engineer on the SP. He told me one time that the horn got stuck. Someone had to go up on top of the engine to turn the air valve off right at the horn. With that thing blaring, he probably lost his hearing that day. He said they then went back and ran the train from the second unit. There must’ve been some surprise at the grade crossings when the lead unit went by with nobody in it.