I did some experiments with a 71 car train (most cars somewhere near the NMRA weight recommendations), using four Athearn switchers, like these…

…and four Bachmann Consolidations…

…with all 8 locomotives having added weight.

I ran the train using the four diesels in various configurations: four on the head end, then two on the front and two on the rear, and all four distributed fairly equal throughout the train. I then repeated the process using the Consolidations, and again using a four-engine mix of steam and diesels.

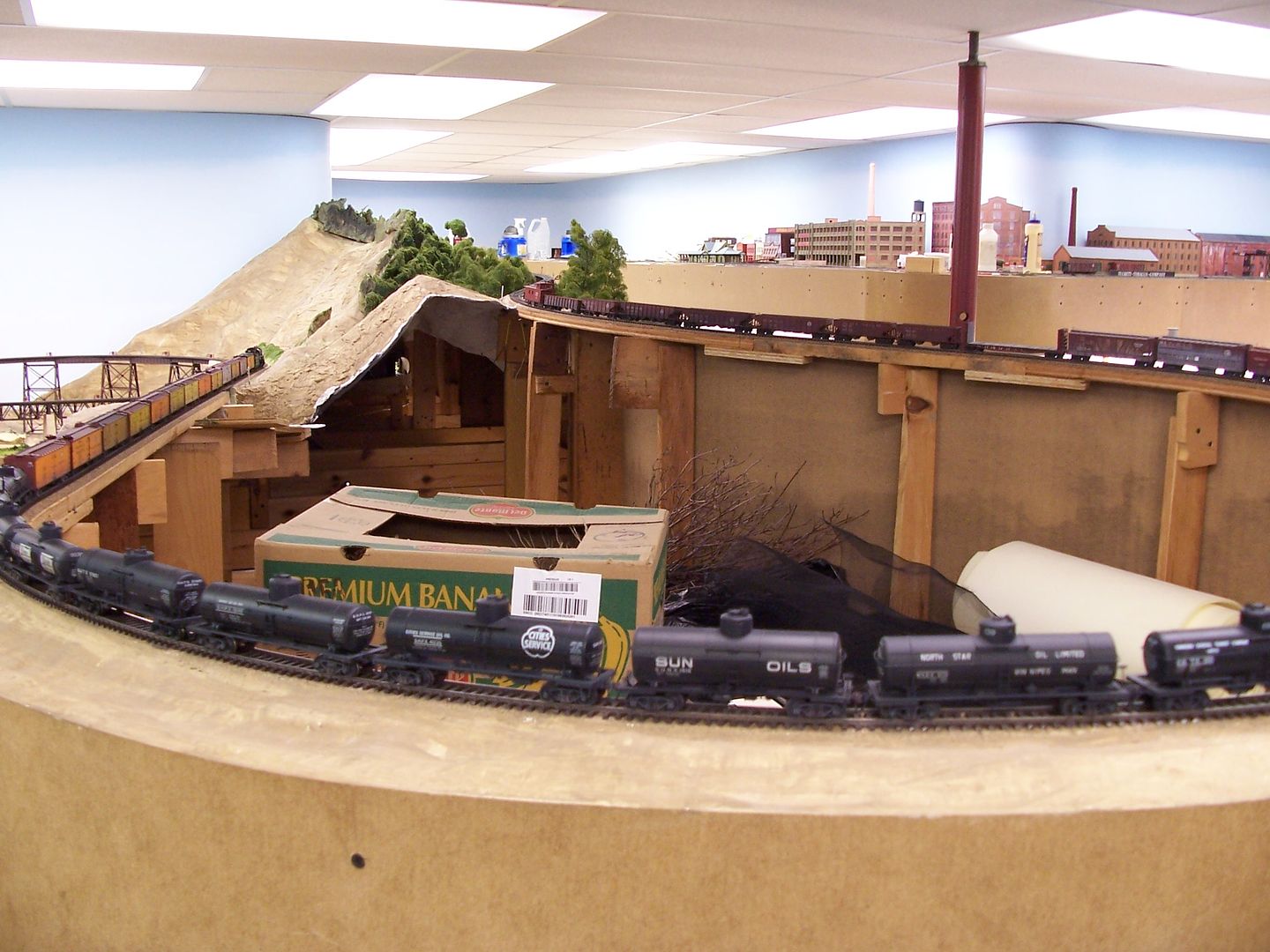

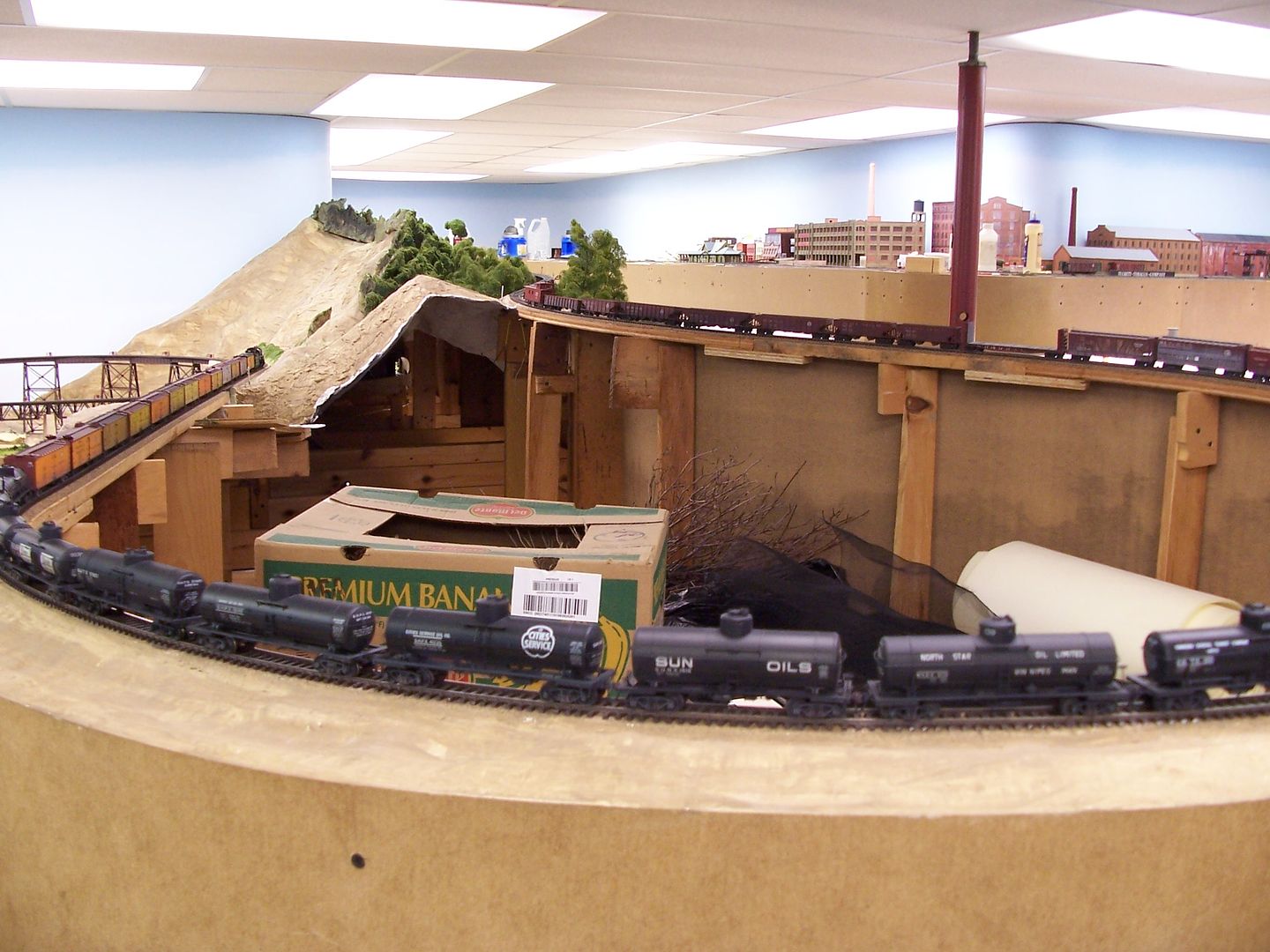

The grade is 2.8%, laid out over two horseshoe curves, followed by a series of “S”-bends, and is about 45’ in length…some of it is shown in the photo below…

…when the track ended at the top of the grade (the partial upper level hadn’t yet been built)

(the train shown is not the test train)

What I found was that the train was moved successfully, regardless of where the locos were placed within the train, or which combination of locos was used.

I also noticed, when running the same train on other parts of the layout, with two locos leading and two pushing on the rear, and also with all four on the front (most of the layout has a varying up-and-down profile) the run-in and run-out of the slack, when first noticed, verged on terrifying to see. Different parts of the train were moving almost like an accordian, although there were no derailments.

All-in-all, I was both surprised and pleased with what I learned. I don’t normally run trains of that length