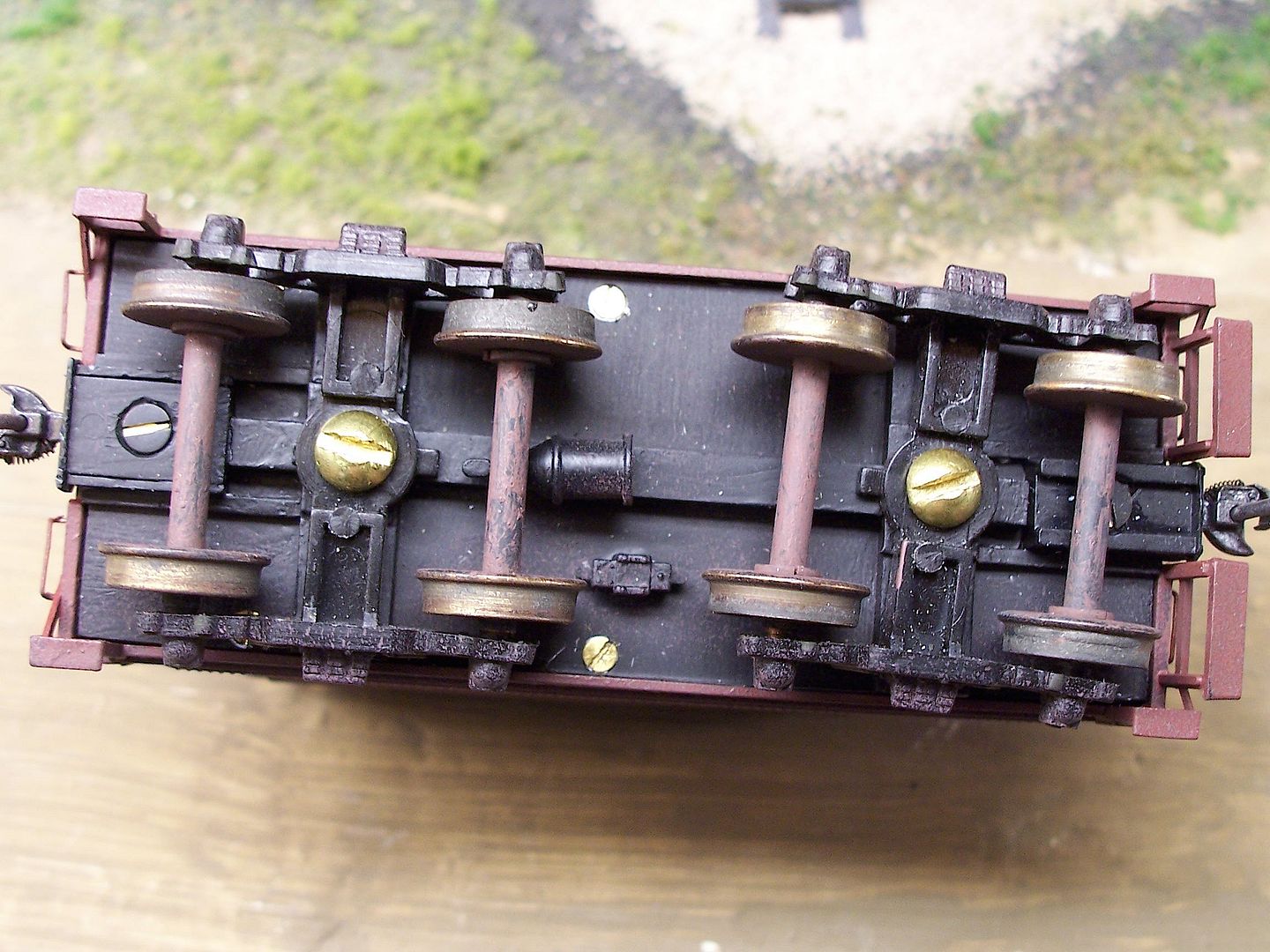

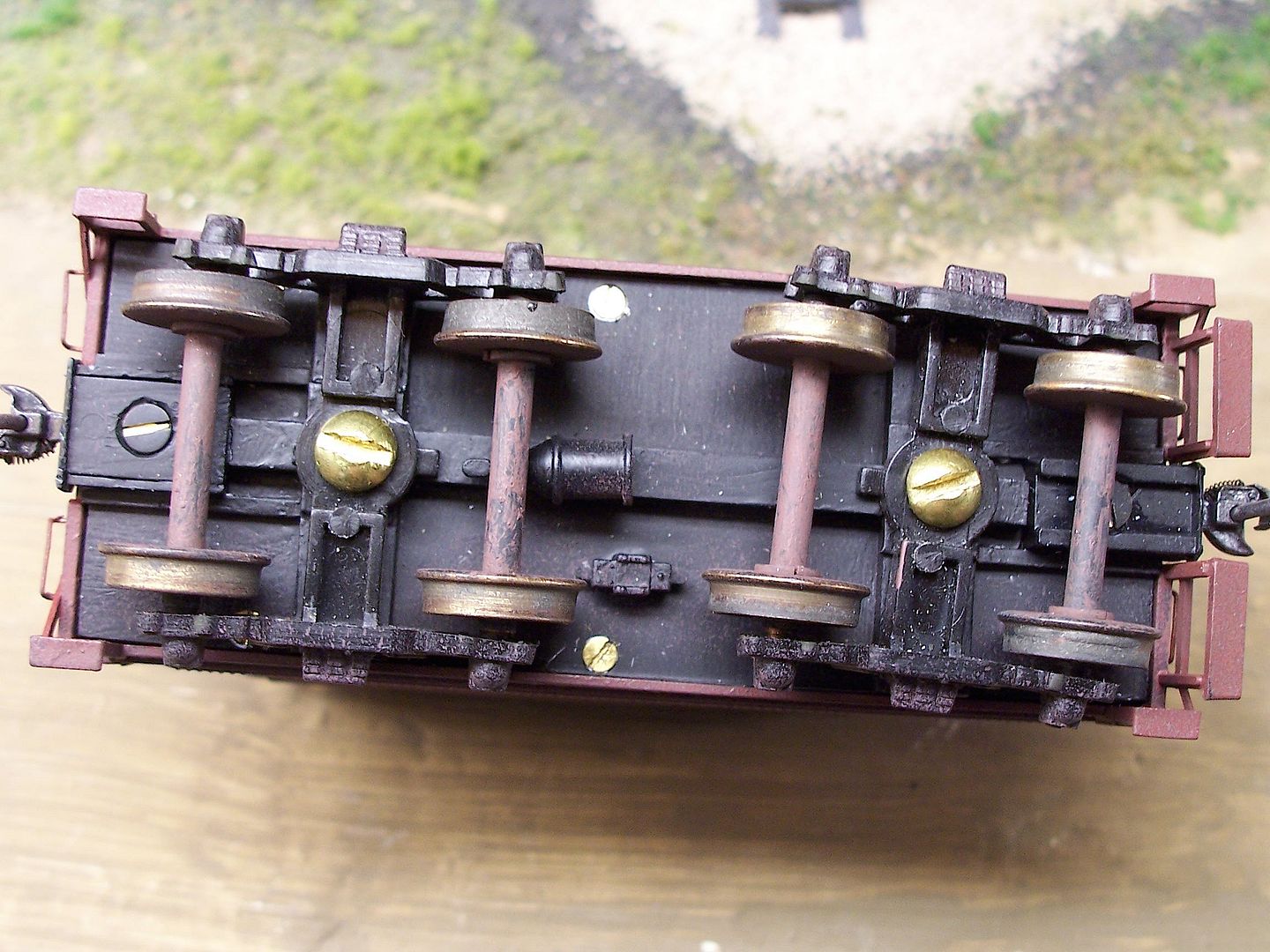

For securing trucks, I use 2-56 screws, rather than the plug-in plastic ones. Many of my older Accurail cars used the push-in plastic coupler covers, too, and in most cases, they work well and stay in place, and can be removed and re-used if a coupler needs to be replaced.

For pretty-well all types and brands of rolling stock, 2-56 screws work well for mounting trucks.

For Athearn cars, the clip-on metal covers for couplers work very well, provided that the sides are at 90º to the face of the cover.

For more recent Accurail (and other) offerings, the coupler covers are screw-mounted, and my more recent ones, regardless of manufacturer, use flat-head 1-72 screws, or, when necessary 2-56 flat-heads.

I use a numbered drill bit which matches the size of the screw’s head, in a pin vise, to create a countersink so that the screws’ heads are not visible when the cars are on-layout.

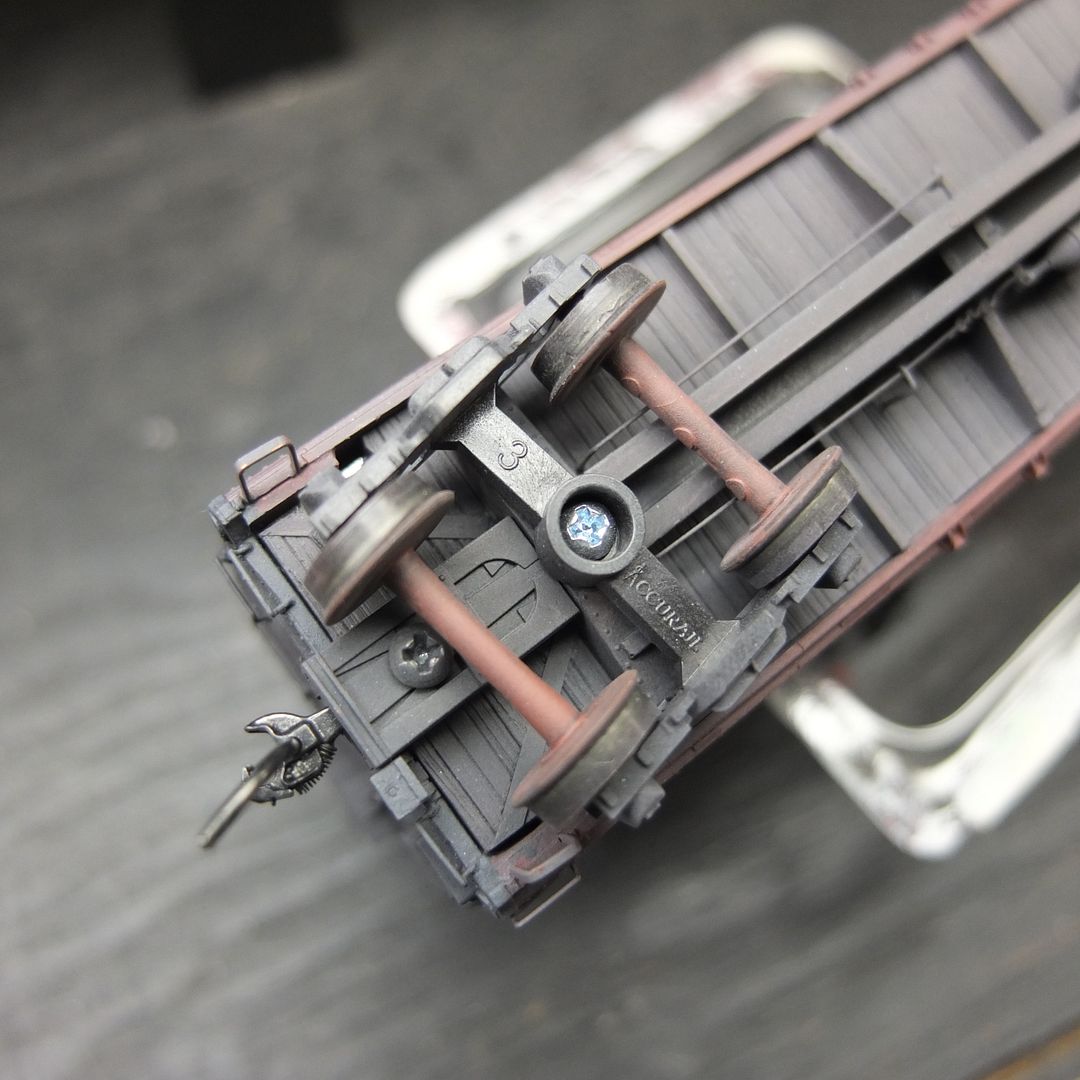

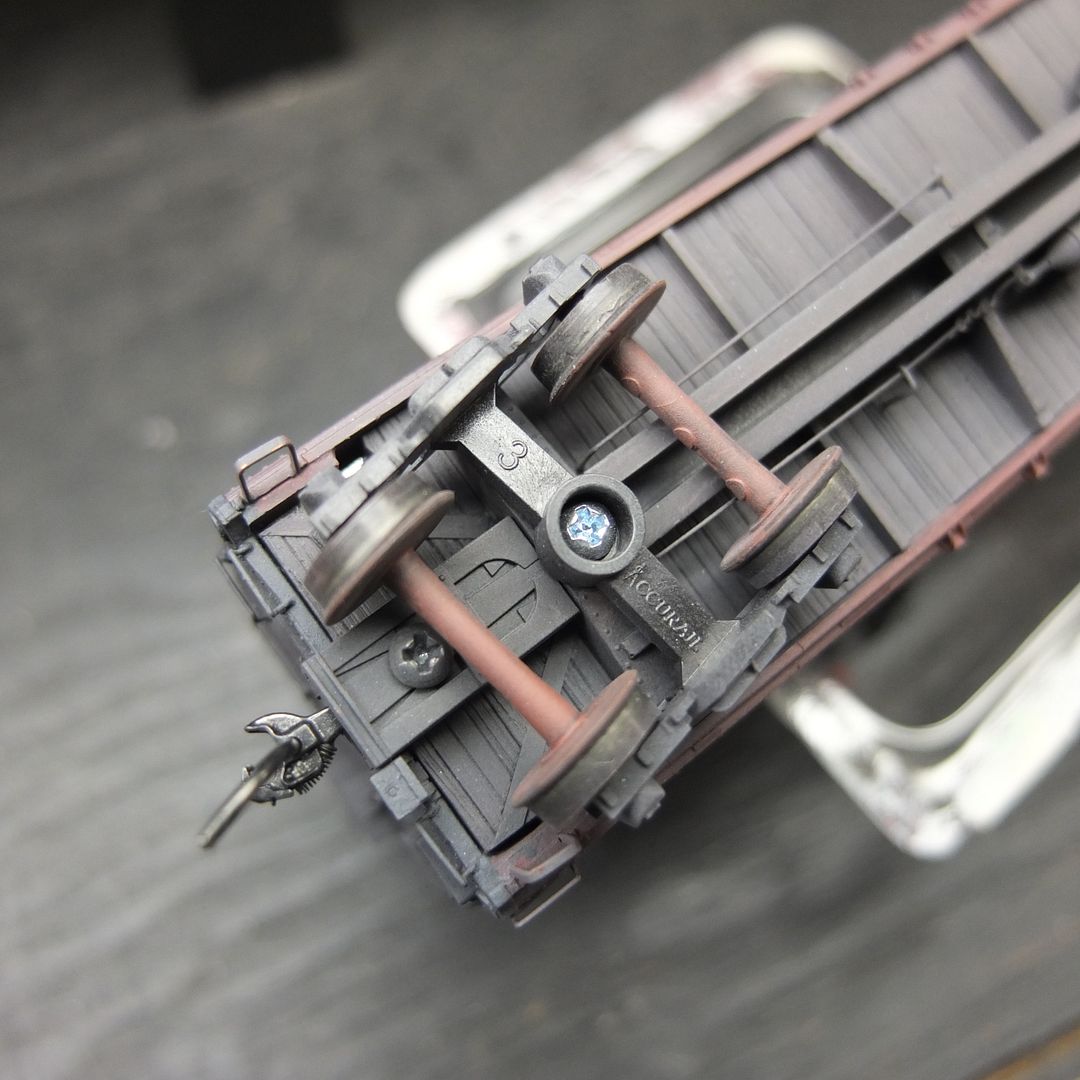

Here’s a Proto stockcar with Kadee couplers in Kadee draught gear boxes, secured with partially counter-sunk flathead screws…

…and an older Accurail car with the press-in coupler cover held in place with a screw…

This little MoW car, an MDC old-time tender…

…uses countersunk flathead screws to hold the car’s body to its underbody, and to hold two different Kadee draught-gear boxes in-place…

If you have screws of a suitable diameter, plus a nut with compatible threads, you can convert the too-long screw into one of a more appropri