I need a relatively small control panel (8 X 10 or 11 X 14) for contolling turnouts in a staging yard. I am thinking of using a cheap frame with acryllic lens. Any experience, thoughts or recommendations on this?

Thanks in advance,

Mark

I need a relatively small control panel (8 X 10 or 11 X 14) for contolling turnouts in a staging yard. I am thinking of using a cheap frame with acryllic lens. Any experience, thoughts or recommendations on this?

Thanks in advance,

Mark

I built a small wood frame, put it on a drawer slider. I then made the panel out of masonite, I then printed out a cover sheet and glued to the masonite and the put a piece of plex over that, I then drilled the holes and wired the stuff. I then made a pic frame for the panel, and put it on the drawer as a hinged cover . I worked well. I also made a small panel out of 1/4 plex. I drilled the holes and wired it all. I glued plex around the edge for a box. This was a protible light panel for my skid row scene which is portible. That also worked well and it was fun to see into the works. I do not have a pic of the all plex box.

Working with Acrylic is not as easy as working with wood or Masonite. Even drilling a simple hole can crack the Acrylic if you are not familiar with working with it. You don’t want to be using an electric drill by hand. A drill press and a new bit is almost required.

Elmer’s right about drilling the acrylic, a drill press and a new bit (metal cutting type) are key. I would add that sandwiching the acrylic sheet between two flat pieces of material, such as MDF, holding all tightly down on the drill press table, would help.

A disadvantage to using picture frame material, is that the protective paper covering you normally see on acrylic sheet is already gone - this paper helps keep the sheet clean and scratch free while cutting and handling. You might try looking for polycarbonate (Lexan) sheet at Lowe’s or HD, this is a little more forgiving than acrylic (Plexiglas). A very thin (1/32 - 1/16") sheet would be all you need.

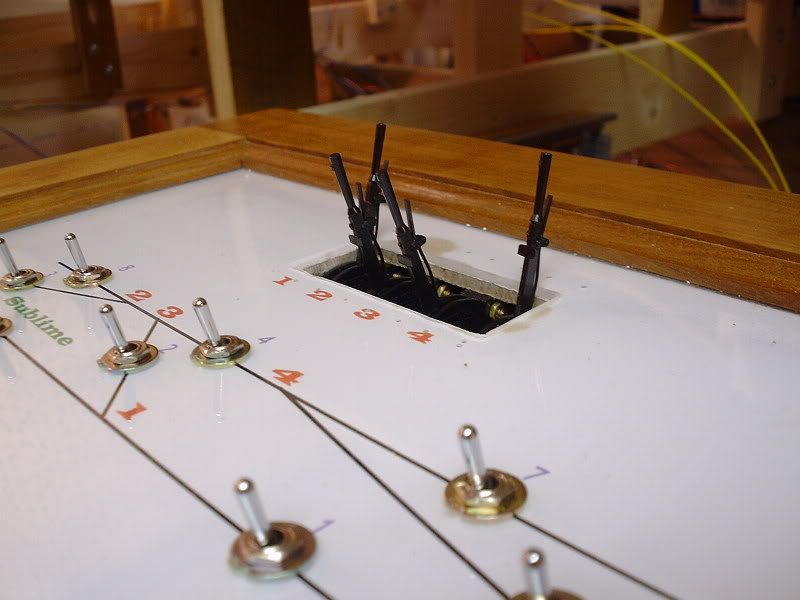

All that said, Arthill’s plexi panel looks nice…

Ed

In my opinion, and in my experience, the replies so far are dead on correct.

First of all, you should definitely consider Lexan rather than acrylic, because as already pointed out, Lexan is more forgiving than acrylic which easily shatters when drilled.

Second of all, as already noted, even Lexan can split when drilled. Here is the way that I drill holes in Lexan to hold toggle switches and LEDs. I need to drill 1/4" holes in Lexan for my control panels. So, I start with a small drill bit, usually 1/16" but no more than 1/8". The smaller drill bits will not crack or split Lexan. Then, I gradually increase the small diameter hole with a slightly larger drill bit. Once the hole is large enough to accept a reamer which will enlarge the hole to 1/4", I finish the hole that way.

Here is the reamer that I use:

http://www.micromark.com/T-Handle-Reamer,6640.html

Rich

Art: nice looking control panel. Isn’t it amazing how many wires wind up behind these panels?

I use Lexan for my panels too. Home Depot has it in different sizes. To hold the panels, since I like them fixed to the front of the layout and slanted upwards, I make a box with triangular sides and route out a lip in the front for the panel to sit in. The bottom is solid but the back comes only part way down leaving a space for the wires to exit. Since my carpentry skills range from abysmal to poor, the boxes aren’t the prettiest things but they do the job.

For drilling holes in the Lexan and in sheet metal, I use a step drill bit. It’s a cone-shaped bit with steps at the standard drill sizes, getting bigger the farther up the bit. I can feel each step as it cuts through and drops to the next largest step. Since it has only one vertical flute for cutting, it doesn’t catch on the material the way a twist drill will. It can start its own hole, but the tip isn’t all that sharp so I prefer to drill a 1/16" hole to give it something to start on. Step drills come in different size ranges and can be found at any good hardware store that sells power tools and accessories.

Here is one of my control panels using Lexan and a reamer to drill the 1/4" holes in the Lexan:

Rich

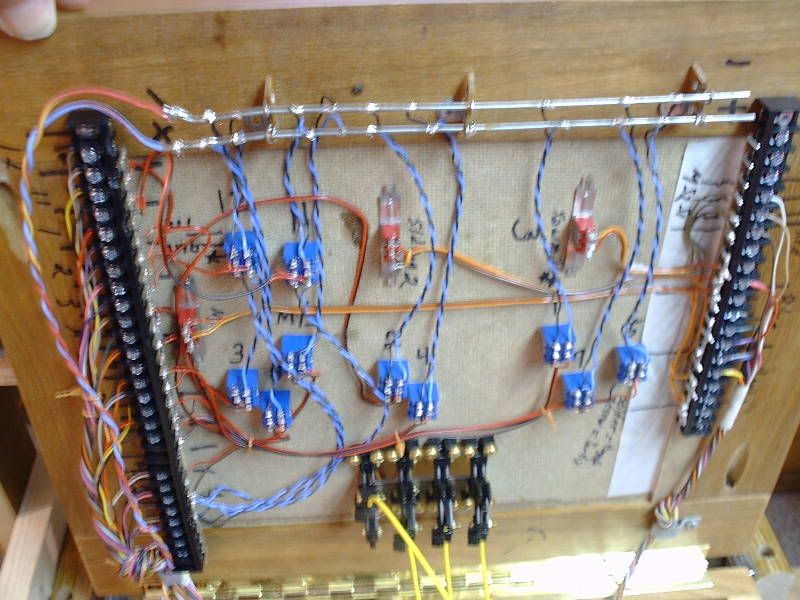

Nice, but LIONS go for BRUTE FORCE control systems: