Hi Guys

I have a cylindrical hopper that seems to derail alot ( especially on turnouts ) I have changed out wheel sets ans still the same thing? I’m starting to think that its underweight. What can I use to add some weight to it?

Thanks

Jeremy

Hi Guys

I have a cylindrical hopper that seems to derail alot ( especially on turnouts ) I have changed out wheel sets ans still the same thing? I’m starting to think that its underweight. What can I use to add some weight to it?

Thanks

Jeremy

Lead. [(-D]

in all seriousness if you can open up the hopper, pine wood derby car weights will work too, just follow the NMRA guidelines and you may not have much of a problem there…

I have had the same problem with a Bachmann covered hopper and added the “correct amount” of weight to the car, but i placed most of the weight close to the trucks… it seemed to help it,

http://www.nmra.org/standards/sandrp/pdf/rp-20_1.pdf

NOW that was just a weight problem, another might be that your wheelsets are out of gauge, to help with this buy, a NMRA Standards Gauge

http://www.handlaidtrack.com/NMRA-Mark-IV-HO-Scale-Standards-Track-Gauge-p/tl-0005.htm

It will help find out many problems you could have like your turnouts might also not be in good standings,

also which direction are you rolling that hopper through the turnout?

Thanks for the lead tips.

I have a NMRA gauge and everything checks out good. So I am just hoping its a weight issue.

Jeremy

If you can’t open it drill a hole in the bottom and pour in weight. I hear lead shot mixed with white glue works. Shake the car to distribute the weight. You can seal the bottom with epoxy. Once the car is right side up no one sees the hole.

Yep, exactly what I was going to suggest. In a car like this, you could get away with not adding glue to the shot that’s going inside, just use it to seal the entry hole. Without the glue added to the shot, you can get away with a smaller entry hole.

If you can not easily remove any of the hatch covers, drilling the hole as JOE323 suggests is probably the best way to go. Another thing to check is if the roofwalk can be removed. If you can not find lead shot, you can use BB shot. WalMart or any store with a sporting goods section would have this.

Many covered hoppers like Athearn have a weight that sits in top of the discharge chutes, so drill a small pilot hole first to see if there is any interference with your planned large hole location. Drill as high as you can on the discharge chute, than add the weight and glue. Let it sit upright so the weights go to the bottom of the chutes to keep the center of gravity of teh car as low as you can. Seal the hole, match the paint the best as you can and weather to cover up any paint mismatch.

Depending on how many cars in your fleet, you may want to considder getting a digital scales. I have found most cars are underweight and need an ounce or more added to get them up to NMRA standard and running better.

I agree with all the above advice but I use my wifes old diet scale for weighing the cars The readout is analog but close enough.

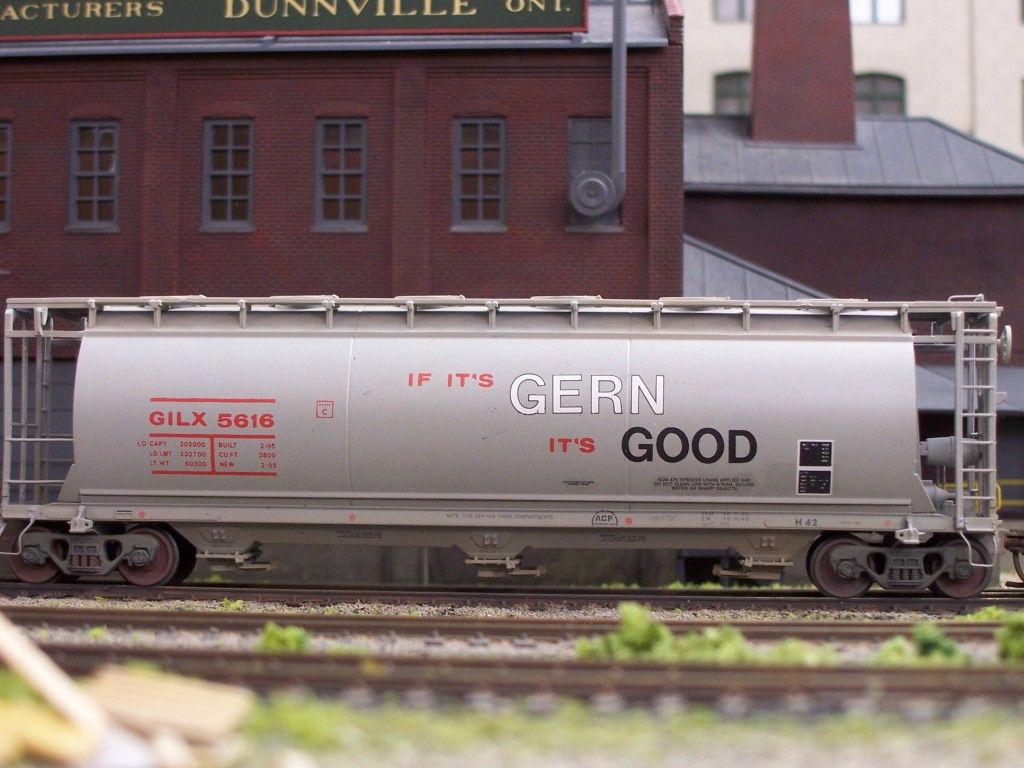

Depending on the car’s manufacturer, it may or may not be easy to open. While the car below, an Atlas r-t-r covered hopper, didn’t need extra weight, I needed to take it apart to strip some of the original lettering and some which had been added by the car’s previous owner. Nothing was glued, it simply snapped together or was held with interlocking joints, and it was just a matter of determining the proper sequence of dis-assembly.

Wayne

I’ll add a vote for BB’s and white glue. You do not need to get the glue on the BB’s before adding, just pour them in. Put the tip of the white glue bottle up to the hole and insert a good shot of glue. Have a piece of sprue or other plug ready to put in place. Make sure there is no white glue residue on the hole, insert and glue in the plug. The plastic glue sets up rather fast, so after a few minutes, gently rock and shake the car to mix the glue and shot together and evenly distrubute it over the length of the car. Then let it sit for some time, because there is no air movement in the cylinder to speed the white glue drying.

To determine the correct amount of shot to use, place a small plastic cup on the scale, then zero it (or note the weight of the cup to be subtracted later.) Place the car on the scale and add shot to the cup until you have enough. You could be a little short as the glue will add some weight. Could even return the car to the scales on its side to see if you need to add more shot or glue before putting in the plug.

Good luck,

Richard