Hello All,

I have a cow & calf set of those same Athearn B.B. locomotives; AKA TR & TR2.

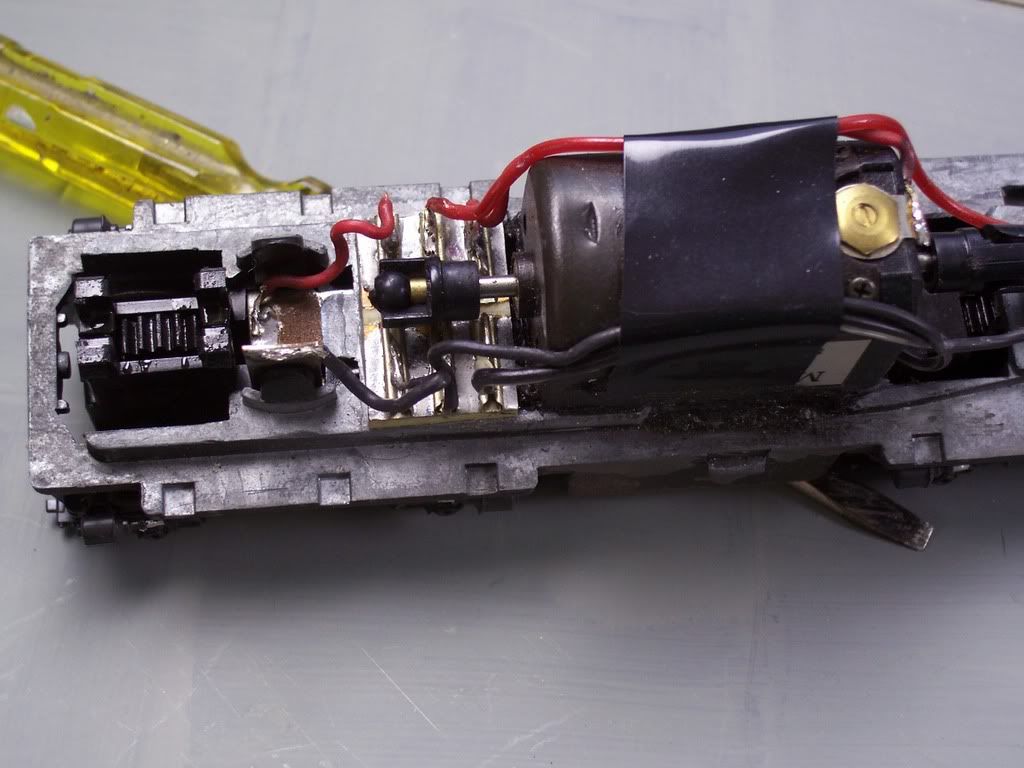

One of the problems with B.B. locos is that they use the frame as an electrical conduit as well as the metal strip on the top for the other electrical path from the rails to the motor.

The motor brushes are held in place by these metal strips and a spring for each brush.

If the spring(s) become compressed the brushes will not make consistent contact between the metal strips and the motors’ armature.

You can carefully remove the metal strips and “pull” the contact springs to elongate them.

When doing this be careful to not lose the brushes. (These aren’t “brushes” with bristles, they are small cylindrical pieces of material that press against the armature. After time they wear down.)

Elongating the springs can compensate for a worn brush(es) but only to a point.

Inspect the brushes, they should be about 1/8-inches long and be concave on one end from contact with the armature. If they are smaller you might need to replace them.

When reinstalling them make sure the concave end is against the armature. This will ensure maximum contact with the flat end of the brush and spring.

The good news is Athearn still sells motor brushes and springs. I recently purchased a pack of replacement springs.

Isolating the motor from the frame will solve a lot of problems even in DC. In DCC this is a MUST.

Check out this thread: Athearn Blue Box motor replacement.

Those old open-frame motors can draw alot of current (amps) and run hot.

Unfortunately, upgrading to a modern can motor will require milling out of a portion of the frame for the new motor to fit.

You can use a rotary tool with a high-quality bit.

I know this because this is one of the projects on my workbench.

Hope this helps.