I bought a number of assembled DPM and Walthers kits (all fairly small structures) at a train show for a very reasonable cost.

Some had been assembled using tube glue, and some using ca, but all were done rather sloppily (glue all over portions of the visible sides and parts incorrectly positioned, causing misalignments all over the place.

Almost all of them were easily taken apart, and the excess glue removed using suitable knives and/or sandpaper.

I’ve reassembled most of them, although a number of them still need to be painted.

I also have quite a few Walthers structures on my layout, but don’t recall too many of them with casting defects or too-small gluing surfaces. I don’t think that I have more than a couple Walthers kits that were built strictly to the kits’ directions, as most are modified or made from multiple kits, either alike or totally different.

If a kit has poorly-formed gluing surfaces, I simply remove the defects with a knife or sandpaper and files, then use sheet or strip styrene to create new gluing points.

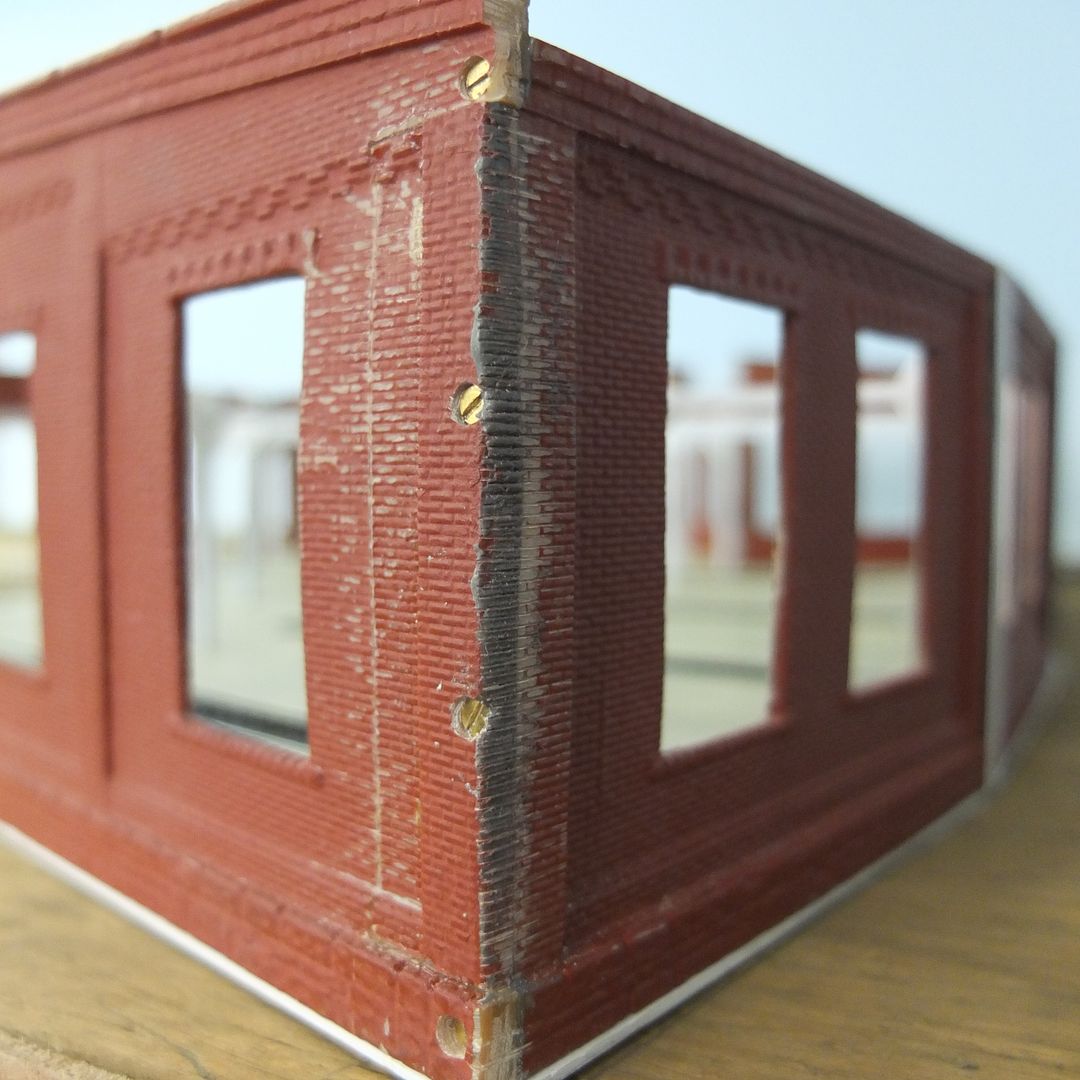

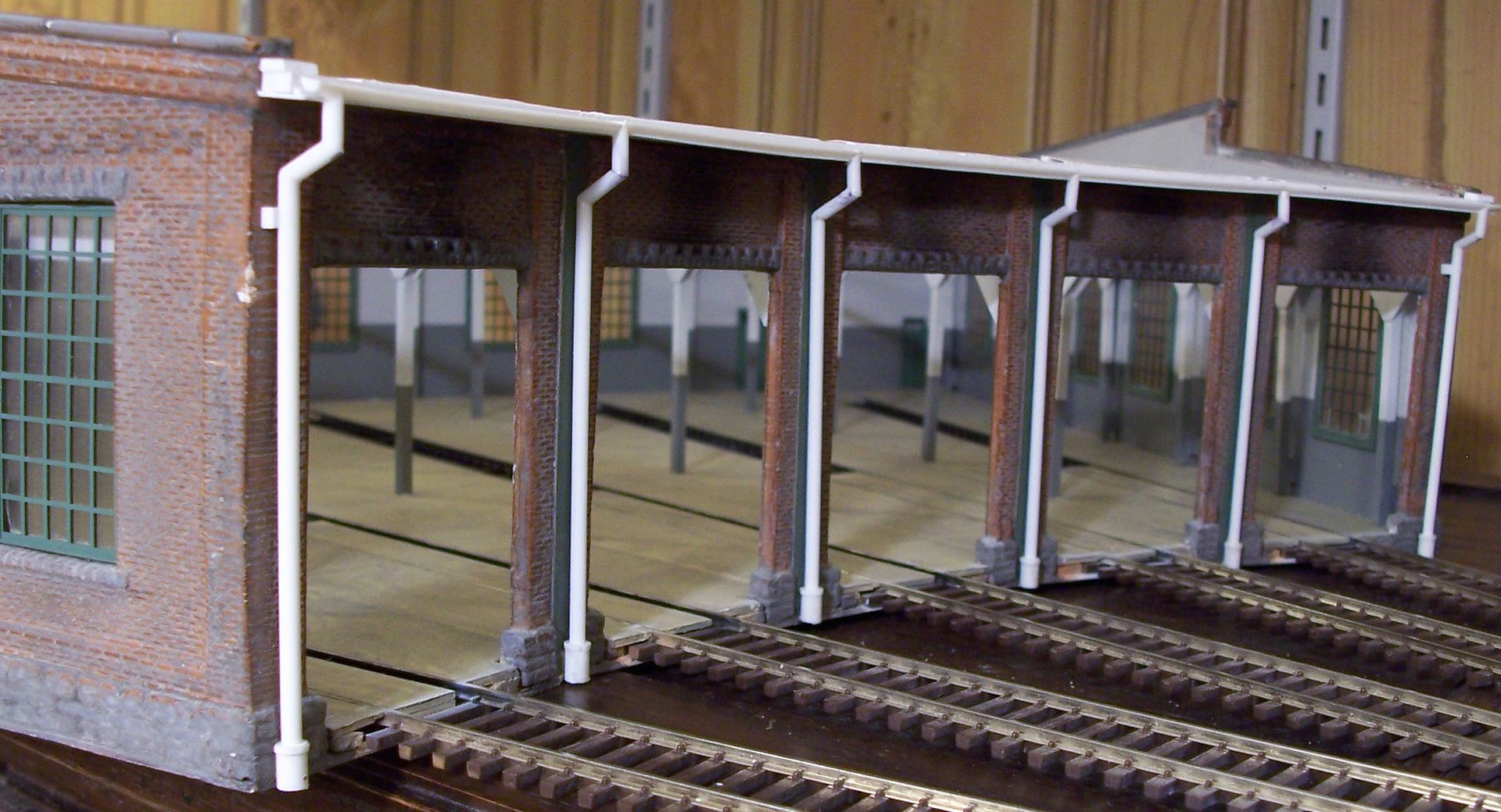

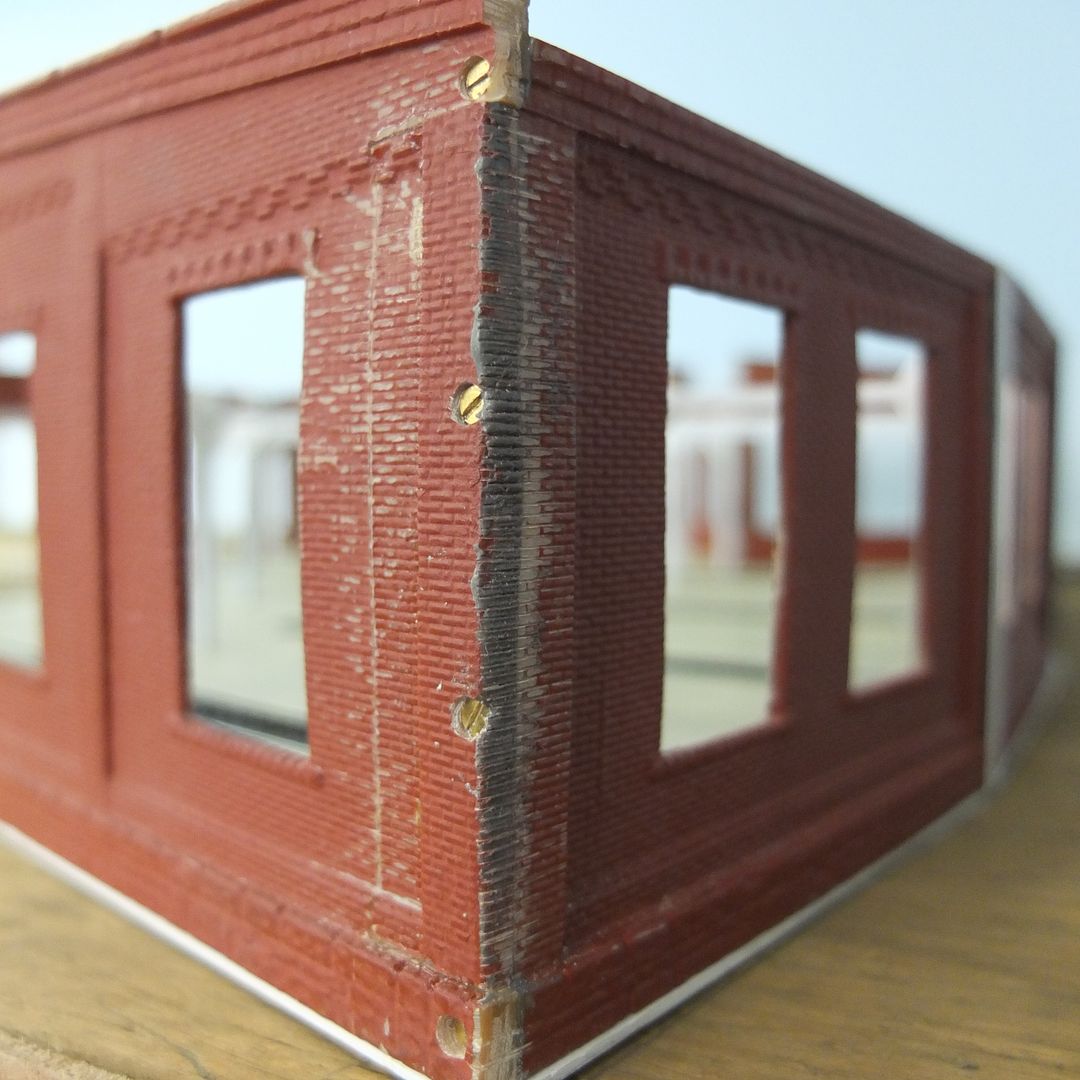

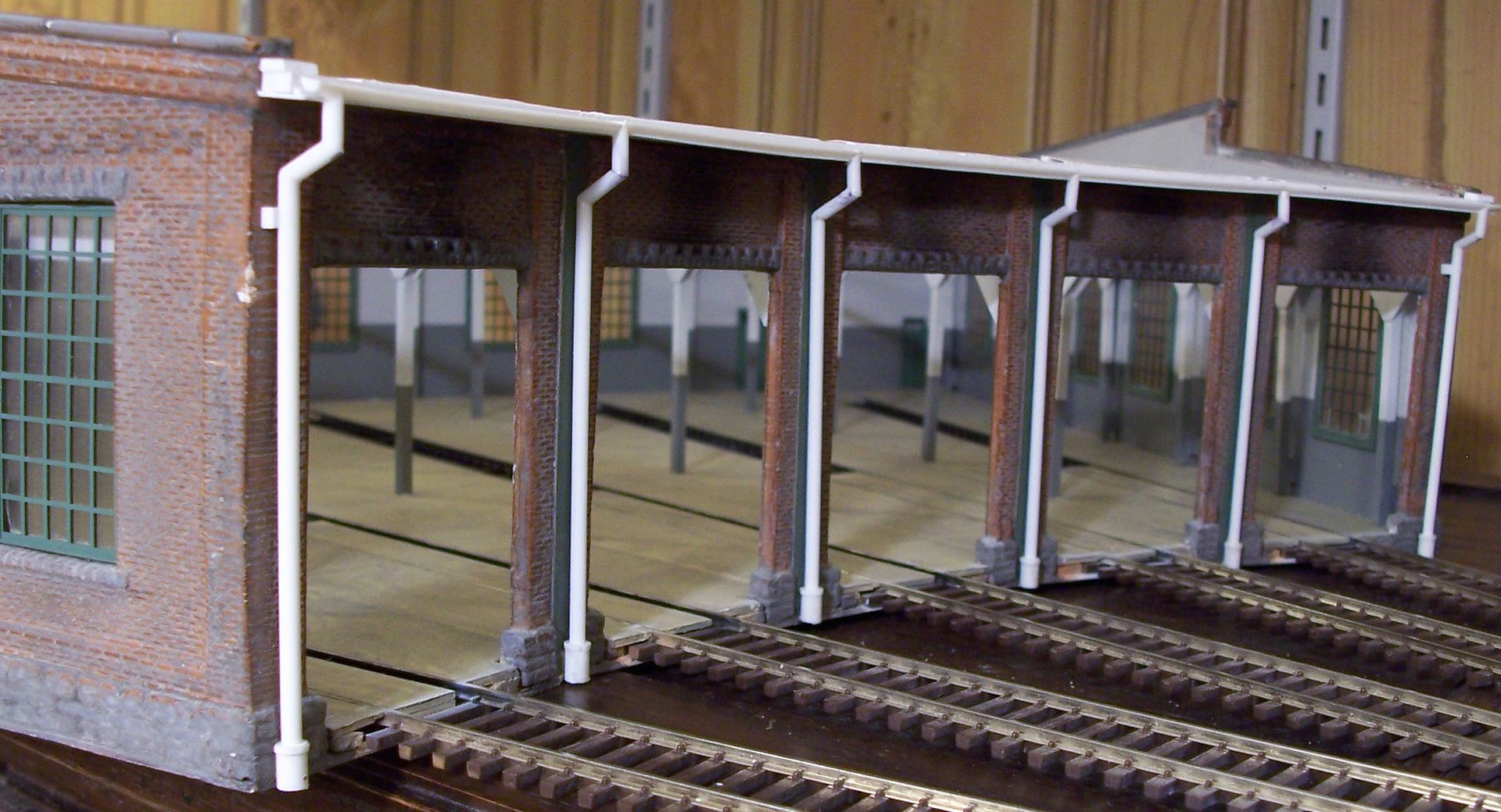

Where necessary, especially with warped parts, I’ll also use the above-mentioned materials, drilling, tapping, and countersinking, using appropriately-sized flathead screws to make strong permanent joints - this is especially useful when the kit being assembled isn’t all made of styrene, like this Korber roundhouse, made with resin castings…

For this kit, solvent-type cement was useless, as was contact cement, ca, and, until I combined it with plastic H-columns, WeldBond epoxy.

The H-columns and Weldbond hold the front wall segments…

…and those of t