The placement and spacing of the blast bores depends on what sized muck you want to clean up after the shot, and where you want to pick it up from. The techniques vary widely depending on whether you are blasting a road cut, a quarry, the live end of an adit or drift, or raising a stope.

The blasts within a single shot are time delayed, to achieve the effect desired. Usually the earliest bores detonated are used to fracture the rock, then lifting charges move the fractured muck out to where it’s easy to haul away.

Another variable is whether you are able to get your drilling equipment up above the face you want to create. If not, or if it’s too expensive to do so, that rock will be face drilled and will show a different pattern of boreholes after the shot, if any boreholes are visible at all.

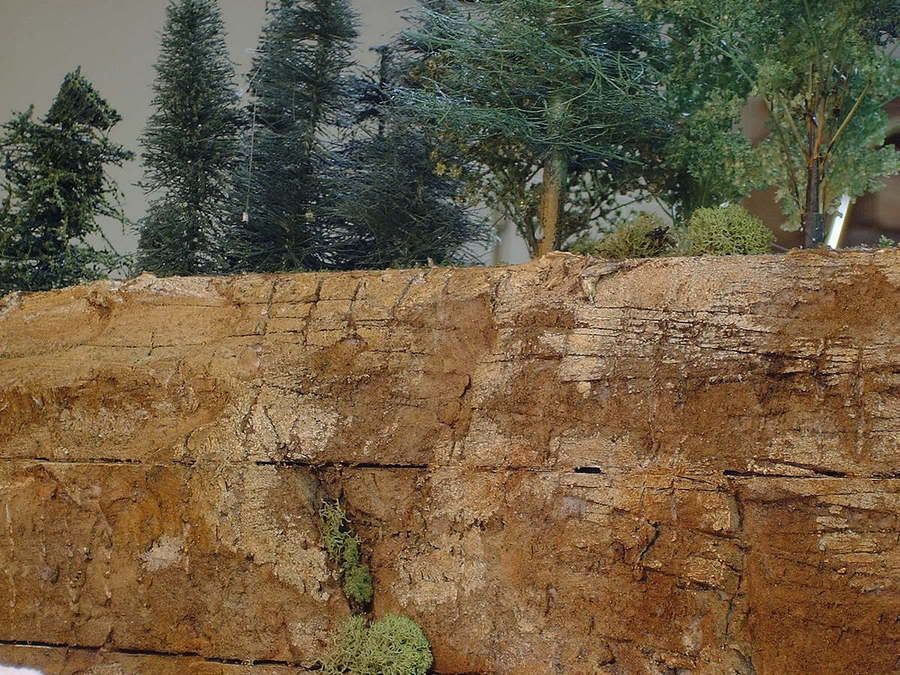

Yet another variable is the nature and quality of the rock being cut. Loose, soft, or friable rock, ash and some sedimentary silts may not show boreholes after the work is done, as the charges themselves obliterate traces of drilling.

In some situations, porous formations allow water to seep down behind the blasted face, and freeze and crack off the original face, obscuring the borehole patterns. Areas like these are often subject to frequent falling rock and steps are taken to reduce the objective danger of same, steel cables, mesh matting etc. During a trip to photograph the Heritage Golf Tournament back in the mid 80’s, a large face fractured and brought a section of rock down on a major NC freeway, near Asheville, if memory serves, several hundred yards long, 150-200 feet tall, and at least 50 feet thick. It closed a major tunnel, and four lanes of freeway traffic were diverted to a single lane dirt fire road which inspired less confidence than many of the 4WD only turn of the century mining roads I jeep on in Colorado. Obviously, no boreholes were left visible on the new road cut face.

In the Red Mountain Mining District of Colorado’s San Juan range, many mines still