I’m thinking about building one, but as far as I know, I’ve never encountered a real one. I’m assuming they were outlawed at some point. How late were wooden truss bridges still in use?

Its been a long time since we’ve been to Durango but the Hermosa Creek Bridge on the Durango Silverton was still in service in the 80s.

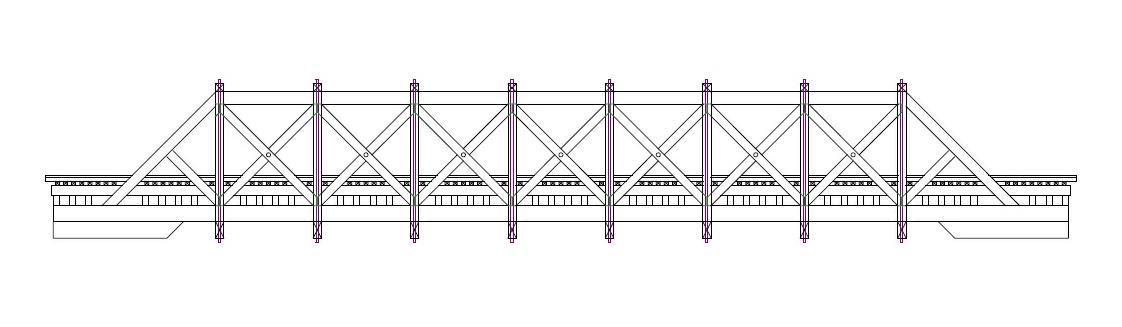

I think this picture was taken in the late 90s.

The Durango Silverton is a great ride, book early. When we did several rides in the mid 80s it was tough to get tickets for early June in January. Take a sweater, it snowed on us at Silverton in June several times.

EDIT:

I don’t see why they would be ‘outlawed’. If the wood, fasteners, supports, and engineering are sufficient for the loads, the railroads would ostensibly use them and continue to make money. If one had to worry about fire, then trestles would have been replaced earlier for the same reasons, but many of them are still in use…and burning. We lost a large one in Alberta a couple of years back.

The fact is that, where it made sense, the railroads’ druther was to fill rather than to bridge. Where filling was possibly going to be iffy, say during spring runoff, they bridged. Where steel trusses made better sense due to increasing loads or local forest fires, then steel was put into service. This happened to the famous arch deck truss Stoney Creek bridge in the Canadian Rockes. The longest trestle in the world is the steel deck one over the Oldman River in southern Alberta, known locally as the High Level Bridge. It was built out of steel from the get-go.

You have to enjoy what you want on your layout. Everything is possible, including lack of funding to rebuild or to replace damaged and aging bridges. Even then, there’s nothing stopping an enterprising railroad from constructing new bridging from materials they only have to acquire in the hillsides adjacent to the right of way.

A wood truss bridge (built 1936) on a coal mine branch in Canada. Bridge still exists. Don’t know when last used by trains.

Paul Mallery’s “Bridge and Trestle Handbook” should be on every modeler’s bookshelf.

In it, he says:

"Modern timber bridges are built from treated timber, some even of redwood, and usually without cover [as in: covered bridge]. Modern timber truss and arch bridges would be found only in areas which presently or recently had good supplies of timber, such as the Pacific Northwest in the U.S. and throughout Canada. The Sioux Narrows bridge in Ontario, built just prior to World War II, has a 210’ (64m) span.’

Timber bridges would be hand-built from local (more or less) timber, while steel bridges would be kits shipped in from factories. Whoever is specifying materials would run the costs and pick the winner. So, building a wood bridge in the middle of a desert would have limited appeal.

The span of 210’ is 30" in HO. THET is a honkin’ big bridge for a model railroad. It is, unfortunately, a highway bridge. Yuk!

There is also the matter of durability. There are steel trusses on the former SP&S mainline that are over 100 years old, and still being used.

Combine this with strength: what would a wood truss bridge capable of handling 100 ton coal gons at speed have looked like? That would have been the equivalent of the above mentioned SP&S bridges.

I also recommend reading (and saving) this discussion of wood and metal trusses:

https://www.tn.gov/assets/entities/tdot/attachments/chapter5.pdf

Ed

We were in Durango 2 years ago, I do not remember that bridge, but there was so much to see it still could be there.

One of the references above said they were still being made of wood as late as 1946, so that would fit into the transitions era. I may try shortening a CV truss bridge. It is what I “grew up with” on the East coast.

THERE’S an adventure. I’ve got a CV bridge project tucked away, myself.

If you’re talking anywhere after WWII, you’ve got some real explaining to have a wood truss bridge. I’m not agin 'em, mind you. I’m just talking reality. They were getting darn rare.

The CV bridge is a fantastic example of a lightly built steel truss bridge. Except that the SP&S bridges I mentioned earlier are almost exactly the same. And those are definitely main line.

I’d be a bit wary of shortening that bridge, though. How ya gonna do it? If you leave out panels, then the proportions might start looking really strange.

If you need a shorter bridge, you might think about a girder bridge. You can’t get more railroady than that.

Ed

As far as I know they weren’t outlawed. They just weren’t built anymore and the old ones …

The Spokane International/ Union Pacific had a Howe Truss bridge crossing the Kootanai River in Bonners Ferry Idaho:

The bridge collapsed under a ballast train on December 6th 1985.

This website has a nice history of the bridge:

http://www.moosecreek.ch/english/history-prototype-railroad.html

The website is translated from German to English.

Regards, Volker

To add a bit to this: a potentially useful reference to wooden trusses is the Government handbook on covered bridges that Alexander Mitchell IV co-authored (the link is recent on RyPN but I can’t access it from here). The ’covering’ in a covered bridge protects underlying wood truss structure from environmental factors. A section in that handbook goes into why it’s unsurprising that even large diesels don’t overload such a bridge … on the other hand a Howe truss is known for proceeding very quickly to catastrophic failure if “too overloaded” rather than gracefully degrading with plenty of warning…

In ‘the old days’ timber, even of great size and reasonable old-growth quality, was inexpensively available. So was even sophisticated joiners’ labor. But iron and fittings were expensive. Along the way these costs reversed, good welding technologies came along for fabrication and good equipment for placement, the ‘good roads’ and construction industries made structural concrete more available … etc. And then comes the whole discussion of permissible preservatives and their likely effect on waterways and other ‘environmental’ areas of concern.

True dat. Quite aside, my father left me a gallon of creosote oil in a metal tin a few years back. When I craft a wooden trestle, I paint its scale timbers with…go ahead…take a guess. [8D] Unfortunately, that unforgettable and so-pleasant smell doesn’t last more than a few days, not for the teaspoon or so that it takes.

I have taken to soaking a paper towel in a few drops and hiding it away somewhere. Or splashing some on the back of a frame member where it won’t be seen.

When the locally famous Kinsol Trestle was restored six or more years back, the stipulation was that the timbers could only be treated with modern preservatives, so they do stand out against the still-pretty-darned-heavily creosoted timbers in its central Howe Truss. With salmon populations under threat in the PNW, we do whatever it takes to ensure they continue to reproduce and to thrive in our streams, of which the Koksilah River is one. (Coke SIGH la)

Selector, creosote has been deemed a “carcinogen” to humans which means it causes cancer! I like your idea though of treating the wood bridges with it but I’d be careful spreading it around the layout just for the smell.

I have no idea. In a recent Cascade Canyon video on MRVP where the constructed bridges from CV parts. Having never built a truss bridge I have no idea where to start with just parts

I drew up my Truss Bridge on my CAD many years ago. I printed out a full size HO template and built with it Northeastern Scale Lumber. I used Acrylic Oak Stain on it with out a sealer. After sitting on my layout for years it has aged very nicely, looks weathered. K&S .020” brass rod worked for the span rods, Acrylic rust takes care of the brass look.

It was a rather easy build using scale basswood. I used Aleene’s Wood Glue so that it wouldn’t show after applying the stain.

Mel

Modeling the early to mid 1950s SP in HO scale since 1951

Here are links to the Central Valley Instructions and building template

Instructions: http://www.cvmw.com/acrobat/1900_acrobat/1902_rev_2.pdf

Template: http://www.cvmw.com/acrobat/1900_acrobat/1902_truss_diag.pdf

Perhaps they help in your decission.

The bridge floor carries all loads with the help of steel strips. The trusses are for show in this model while in the Campbell Howe truss bridge the complete structure is load carrying.

Regards, Volker

Thanks for your thoughtful warning. It happens that I know this and take precautions to avoid contact with my skin assiduously. The odor, itself, is innocuous in the low exposure rate I enjoy…thankfully.

I may have sounded very enthusiastic about making sure I get a strong whiff of the stuff every time I enter my train room. The truth is that I only do this perhaps once a year, and just enough to get that slight sense of it for a couple of days. Then I forget about it until many months later. Also, the trestle I mentioned only gets the treatment each time I position it on a new layout.

Thanks, again, for taking the time to caution me. [:)]

Sure wish I still had my can of creosote, for similar odorous excursions.

In my motorcycling days, I remember reading in the mags where guys would put some Castrol in a frying pan on the stove while they listened to recordings of GP racing. This was a long time ago, before VHS tapes, even. Sometime in the last century. So the fun event was limited to aural and olfactory. It appears. And perhaps yakkin’, if more than one weirdo was involved.

Ed

I have found that the shampoo T Gel has a smell extremely close to that of creosote, so it could be a possible olfactory substitute for the real thing.

Thanks, they also have a collection of Youtube videos, which I have not had time to review.

Edit The written instructions use monofilament line for cross braces. The Youtube video I looked at uses brass rod. [:S]

I’m in long-term midbuild of a modified Central Valley bridge. The thing that bothers me about so many of the builds of this bridge that I’ve seen is that the tension rods aren’t straight. Which they are, in reality.

I suppose the monofilament would end up being straight, but I would worry about the tension twisting the bridge. My thought was to use piano wire (being as it is quite good at staying straight) and glueing it only at one end of the rod. The other end would be in a slip fit hole. That would negate length change problems caused by temperature change.

Easy for me to say,as I haven’t really done it.

Ed

The design of the bridge comes to your aid. With the bridge floor as the models exclusive load bearing subassembly you can take for the rods what you like best.

I personally prefer a straight wire. Monofilament has to be kept under tension to stay streight. Plastics tend to creep (deflections grow under constant tension) with the result that the monofilament might not stay straight.

Regards, Volker