Actually, they are completely useful on sidings and otherwise. You see, the system you are thinking about has a transformer for each track block. However, many modelers prefer to have only a few transformers (say, two or three) and then use a control panel to route power to the desired blocks. “Transition blocks” aren’t really needed with this system, as you simply make sure to flip the switch before the train enters the block. As an example, here’s my control panel.

It can control if there is power from either my Type V or my 1033 transformers (the system is actually much, much more complex, but now is not the time for that lecture!). If, for example, I set the slide switch to “off” and the green (WSRR) rotary switch to “Yard”, then I am controlling the yard with the 1033 and everything else with the Type V. However, if I want to run an engine out of the yard using the 1033 and onto the other trackage in Menardsville, then I need to turn the slide switch to “on” (the blue L&M rotary switch is already in the right spot). Then, the 1033 is controlling both the yard and the Menardsville trackage and the locomotive can proceed happily between them. The Type V will still control all other blocks. If that makes perfect sense, I must have explained something incorrectly!

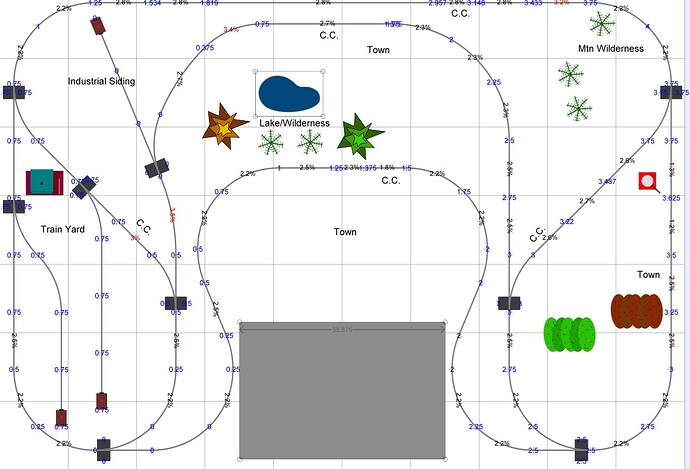

Okay, so if you simply want two or three blocks then it would be silly to design a control panel like this to control them. Simply hook up a transformer to each block and, as a train comes near the joint, try to throttle both transformers to the same approximate position. There will almost certainly be a difference, but probably not enough to cause an issue. However, except for very simple layouts, this would probably be too constraining. As such, I recommend that, if you have one, you post a track plan.

Additionally, on the topic of transition blocks, it might be difficult to wire them if you do decide to go with them. If you simply rely on power carried by the train, it will probably stall frequently. If you want to control it with the transformer, you’re gonna have a fun rat’s nest!

And, to answer your question, the train may or may not carry the connection a great length. If you insulate

all the rails, then it will simply be carried the length of the locomotive (really, just the pickup rollers). Secondly, if you have any lighted cars or really anything else that has pickup rollers, it will also carry the current.