I’m building this Walthers overhead crane.

http://www.walthers.com/exec/productinfo/933-3102

I’m having trouble stringing the hook lines. I’ve used waxed thread and that lycra sewing thread, but the hooks don’t have enough weight to hold the lines taunt. I’m almost ready to try an .006 guitar string. (no local source for brass wire) Any thoughts on using this or any other ideas??

I’ve got a couple of those on my “to do” list. How about attaching a weight to the hook to hold the line straight, maybe a little glue on the string to keep it straight once it has dried. Just a thought.

Good luck,

Is the hook large enough that you could drill out some of it and hide a fishing weight in it? Have you thought about replacing the hook all together with a metal hook?

As for riging I don’t know of anything that would work better than the threads. [%-)]

One hook is metal and the other’s plastic. Both are too small too add weight to. I found some smooth thread that hangs straight, but it’s so thin you can hardly see it. I can’t make my lines very long or they tend to twist up. (one hook requires 4 lines run to it.) Guess I’ll spend $2 and try a guitar string tomorrow and see how that works.

My kingdom for a decent LHS!!

Could you tie a piece of thread onto a small nut, hook the loop of thread over the hook to hold it down?

Good luck,

piano wire maybe

How about… always have something suspended from the crane! [:-^][swg]

There was an article in Mainline Modeler where the author did a mobile crane conversion. He used 0.030 brass wire instead of thread. The effect was very good, except that I thought the wire looked heavier than what I thought would be prototypical. Looking up 0.030 on a conversion chart I found on line, this diameter would equate to 2.61 inch. You mentioned 0.006 diameter wire. This equates to about 1/2 inch diameter. I think you could get away with 0.012 wire, which is about 1 inch in HO. The article author indicated that he had glued the wire to the pulleys, but I couldn’t tell if he used a continuous piece of wire, or used segments and went pulley to pulley.

Thinking about alternate methods (using thread for the cables), graphitehemi above suggested always having something hanging from the hook. Expanding on this a bit, you could make some detachable (unhookable?) loads out of some suitable small steel object. If you have the hook hanging over, say, a scrap pile, you could bury a small magnet in the scrap. The magnet would attract the object on the hook and keep tension on the cables, keeping the thread straight. If you have magnets buried at various places under the crane, you could move the crane from place to place to vary the scene.

Just an idea.

Now I’ll go re-light whatever it was I was smoking when this idea hit me.

Try hair-spray.

Weight your hook down on the finished model, cover around the back side of the string to prevent overspray from getting on the other portions, and spray it. It’ll give it a brittle but stiff finish.

I tried some .008 guitar string but it was to springy and wouldn’t hang straight. Kind of bowed out too much. I think brass would work OK, but I don’t have a local source for it. Gonna try string and maybe starch or hair spray next.

Try using thin copper wire which you get a reasonable length of and put one end in a vice and putting the other end in a power drill and spin it until the wire is nearly at break point. This will work harden it.

You will find that the wire can be kept straight and looked at closely could represent the twisted lines of cable strands and bent around small wheels ( for the pulleys) should help you and yet keep fairly straight… sorry you won’t be able to operate it but I presume that is not an issue for you!

Hope this helps

Trevor www.xdford.digitalzones.com

COPPER! [tup] Didn’t even think about that![D)] I have plenty of types laying around to try. Thanks!

On my operating clam shell bucket (scratch built in HO) I finally found some braided fly fishing line of braided construction that takes acrylic paint and was limp enough for operation and more importantly did not twist. Of course the bucket weighs more than a hook. In addition to the suggestions above you might make the hook out of lead and/or crimp a split shot lead fishing weight just above the hook just like the prototype hook ball. The fly fishing line is quite expensive for the minimum amount. If you wish to e-mail me with your snail mail address I’ll send you some. Gudenuph@gmail.com

FWIW, Geohan

With regard to coloring the fishing line, I should have said “India ink” instead of acrylic paint. Sorry, Geohan

Thanks. I finally got some brand of black thread I had laying around to work. I weighted a long strand of it and hit it with some spray starch. It has more fuzzys on it than I like, but you can’t see them unless your 3" away. I just need to hit the lines with some weathering chalk and I’ll post some pics of it.

Thanks for all the ideas![:)]

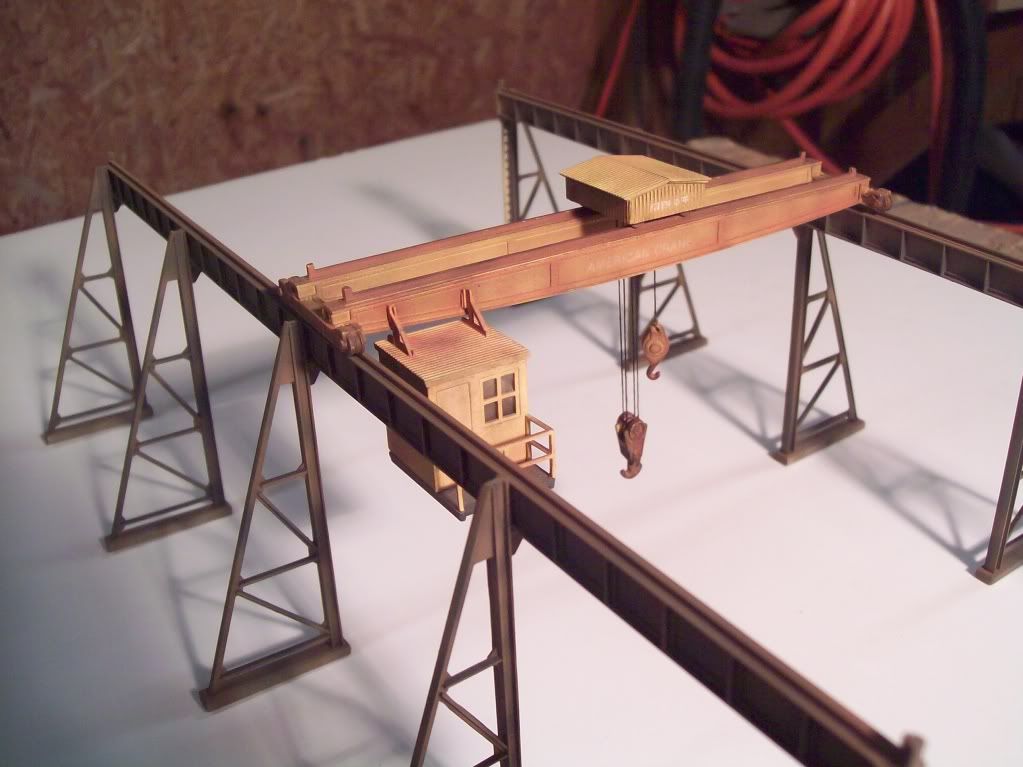

Finally got to take some pictures of the finished crane and lines.

I don’t think it turned out too bad.

Looks good. The fuzzies on the thrread could be burnt off with a candle by carefully moving the thread over the flame, but this is best done before rigging. A lighter may work now that it is done but is risky. The fuzzies don’t appear bad now, but what about dust accumulation?

Looks great! I have thought about building something like that for a team track area I have. Well done, great weathering. Looks like it was well worth the effort.

I thought about trying to hit them with a lighter. I might try that if I get brave enough.

canazar -It’s a pretty EZ kit. Beware though, it got a big foot print! 12"x9". It barely fits where I want to put it.

Excellent.