I’ve had a couple such mishaps.

This one, a Bachmann Reading Consolidation, with a pancake motor, dropped about 5’ to the floor, on a former layout…

Despite its current appearance, it sustained no apparent damage, and is still a decent runner, although it’s not currently in use.

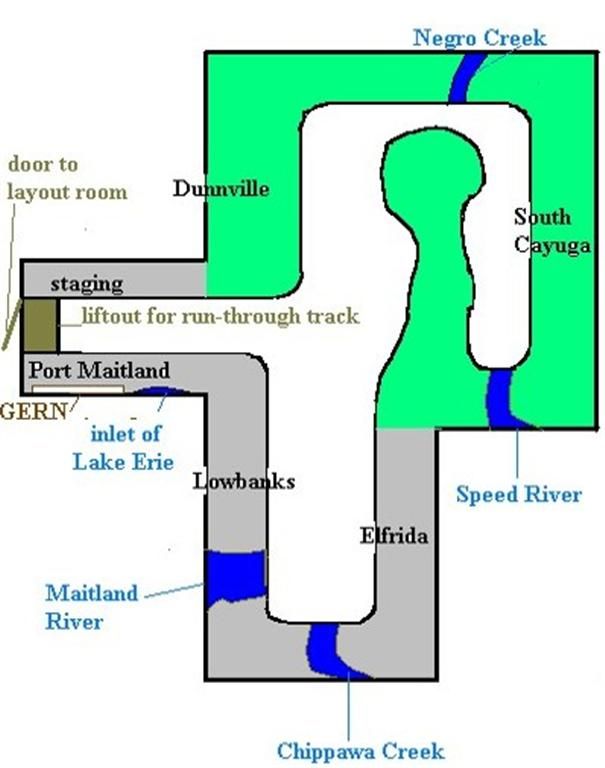

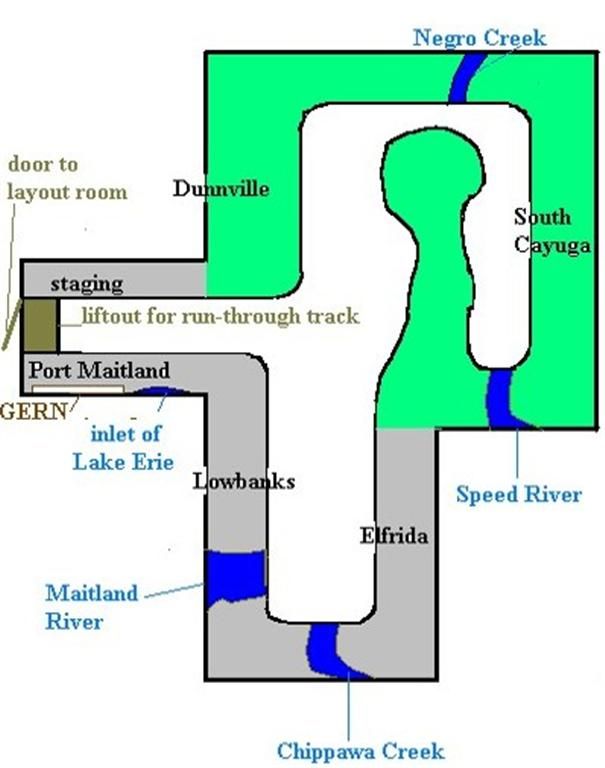

On my current layout, I was doing a little switching in South Cayuga (see drawing below), but thought that I heard another locomotive running somewhere else…

I can’t see the whole layout from that location, so I walked around the peninsula to check that all other tracks had their power switched off (straight DC operation, with all fascia-mounted toggle switches in the “OFF” position).

I returned to my switching, spotting and picking up cars, the locomotive shuttling back and forth as required. I thought that I could still hear another locomotive moving, but because that wasn’t possible, dismissed the thought.

After a while, it was time for the train to move on to the next town. As it trundled out of town, I thought that I heard another locomotive running and a few seconds later, heard something hit the concrete floor.

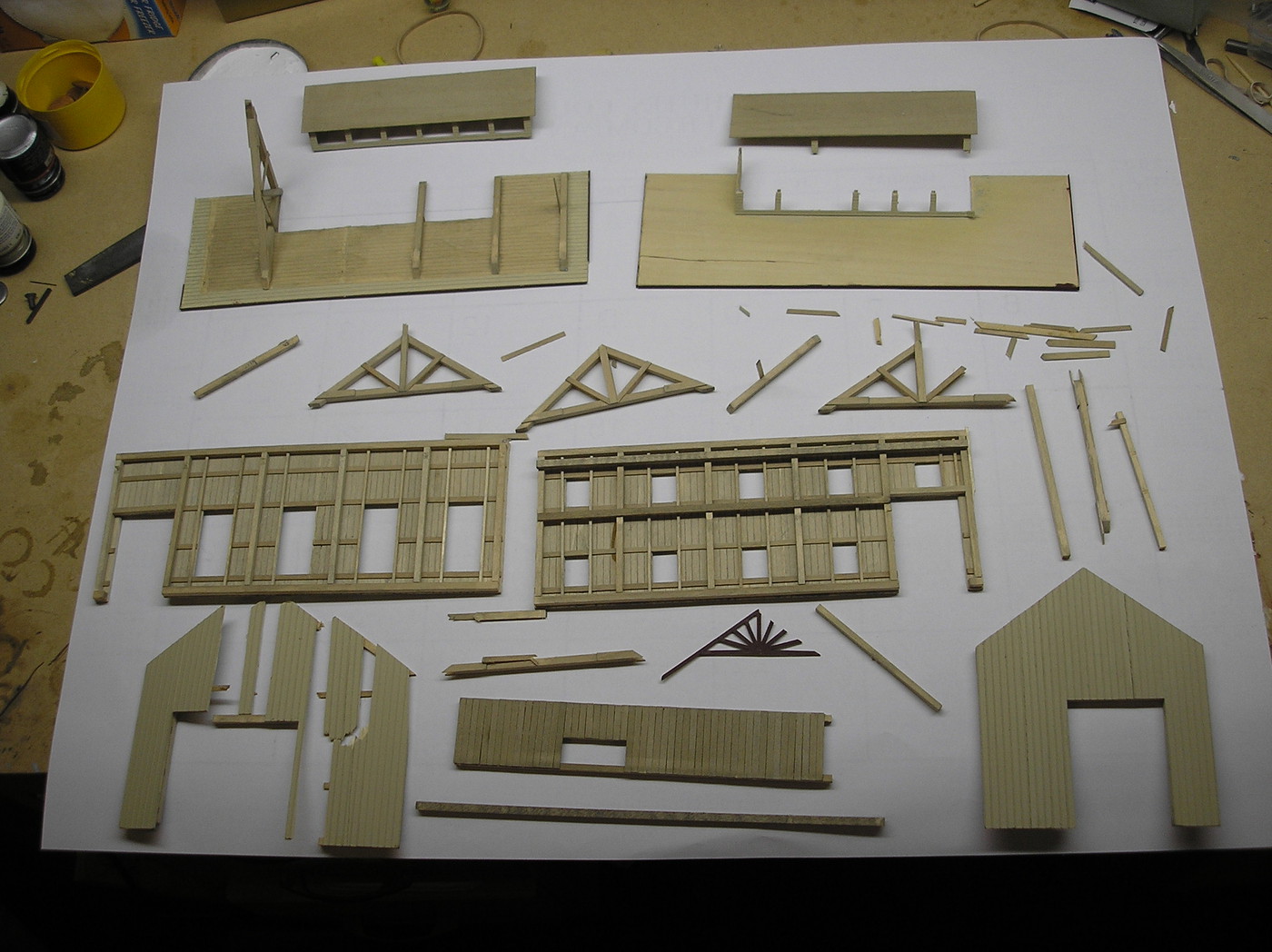

Not sure of where the mishap was, I came around the peninsula and discovered that a locomotive, similar to the ones shown below, was on the floor near the entrance to the room…

…at the time, the area shown was a single track. I usually parked my “coal train” there, as the power to that siding was controlled by the turnout, near the doorway, and it was always<