Understanding steam locomotives are direct drive, has there been any other power units that were direct drive? Has there ever been a diesel engine that was direct drive?

Probably not quite what you are thinking about, but the Fell diesel mechanical locomotive from 1952 might be of interest - https://en.wikipedia.org/wiki/British_Rail_10100

It’s about the closest I can think of to a large diesel loco with purely mechanical transmission.

The 21 torque-converter locomotives sold to D&RGW and SP by Krauss-Maffei in 1961 and 1964 plus the three Alco C643H’s sold to SP could be considered direct-drive locomotives.

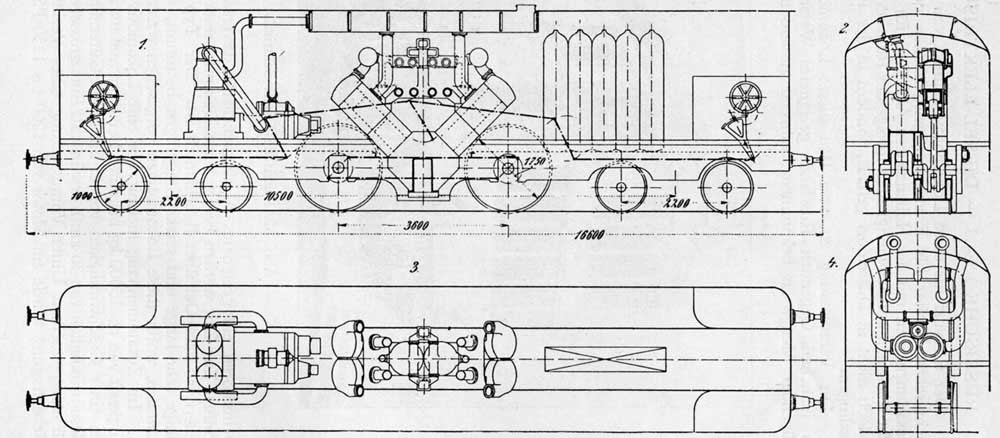

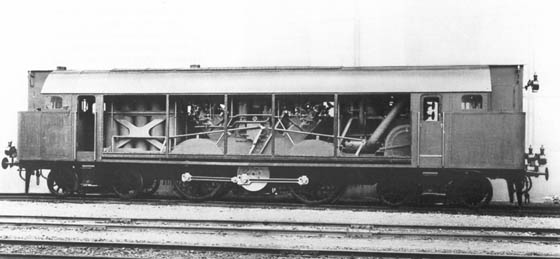

Here is one direct drive diesel

It was built by Sulzer and ran in Germany between the wars.

Think the Sulzer diesel was the first diesel locomotive-- before 1920, wasn’t it?

And the drive doesn’t get any directer than that. Used compressed air to start from a standstill.

There were others too. One German company built a diesel locomotive for the Russians that had a three speed gearbox to a jackshaft drive. It must have been fun to shift a locomotive at speed.

Also the Russians developed several Steam-Diesel locomotives that looked like normal steam locomotives but with two sets of cylinders. One set of cylinders was normal steam cylinders while the other set was double acting diesel cylinders. The locomotive would start on steam and at some speed the diesel cylinders would be cut in for fuel economy. You can read about them here

http://www.douglas-self.com/MUSEUM/LOCOLOCO/russ/russrefr.htm

Depending exactly on what is meant by “direct drive”. Most stringest case is a pure connection by gears or jackshafts, but a looser definition would include torque converters.

A lot of the early early internal combustion rail cars and small locomotives were gas mechanical (e.g. McKeen cars).

RDCs are direct drive (via torque-converter lockup) in their high-speed ‘range’. I should know, but don’t, if the K-M locomotives have this characteristic… but I suspect not, as slack run-in from a train at high speed might break gear teeth otherwise.

There are some good direct-drive steam turbine designs (the Swedish 2-8-0s, the Turbomotive, and the PRR S2 being examples). An unbuilt but approved-for-production locomotive, the PRR class V1, would have had mechanical drive to eight axles (and even more problems than a Centipede with keeping wheel treads in shape!)

I suggest a perusal of Doug Self’s site for most of the ‘other’ direct-drive versions, with careful attention to the rocking-lever Russian OR class (and perhaps the Teploparovoz!) and the Paget locomotive. There are a couple of interesting early ‘rotary’ engined locomotives (think of a reciprocating piston that produces rotating motion directly – better seen than described) that have still not quite been ‘explained’ enough even by the Newcomen Society pundits.

The whole class of ‘motor locomotives’ probably count as direct-drive for purposes of this discussion – there were a number of famous European types, one of which came to the USA after WWII and was shamefully scrapped (after the Germans didn’t want to pay to get it shipped back!) in the Korean War scrap frenzy, and the partially-built B&O W-1 … I leave it to the reader’s ingenuity to give an appropriate Whyte code. In my opinion, some version of the motor-locomotive principle would have been a logical ‘replacement’ for many classes of orthodox reciprocating steam if diesel-electric development had progressed more slowly or been financially less successful.

I’m guessing when the guy asked about “direct drive” diesels he meant direct drive, like a reciprocating steam locomotive. Did any exist, aside from the ancient Sulzer?

The problems with direct diesel drive to wheels are many, some of which characterize the Thermolokomotive … the most important difficulty is that a typical diesel has a minimum effective speed, so you either need a clutch (and probably jackshaft) or compressed air assist (as on the Thermolokomotive) to start the train and get it up to “combustion” speed. (With the exhaust expansion cooling while on air drive cooling down the cylinder head at just the time you want compression heating to ignition temperature…)

The interesting exception to this is the ‘combination’ steam/diesel locomotive, best exemplified by the Kitson-Still or … something like this:

The basic idea is to use typical locomotive-pressure steam on one side of double-acting pistons (usually the ‘end’ with the piston rod) and compression-ignition cycle on the other, with the combustion exhaust passing through a HRSG stage which … theoretically … recovers some of its waste heat to the Rankine cycle. As it turned out in practice, there is precious little recoverable heat compared to the additional complexity involved in using it, and there are some consequences for emissions that didn’t factor into the design process ‘back then’.

There are Russian enthusiast sites for those things. I can see why.

Thanks for the note back. This is right on point for what I was wundering about, the complexity of the drive system is amazing.

I am know about the Voith Drive Technology in the marine side of industry, never knew they designed systems for the rail.

Thanks

Thanks to ALL of you for the help. Each of you has given me plenty to ponder. The Russian units are the wildest in my mind combining steam and diesel.

My understanding of the Voith transmissions was that they did not have a provision for locking up the torque converters. The tranny’s had three torque converters, ech with a different gear ratio and “gear changes” were accomplished by draining the oil out of one torque converter and filling another - apparently very smooth process. Efficiency at optimum speeds was about 85% and it dropped off at higher or llower speeds - suspect optimum scaled somewhat with engine rpm.

FWIW, gears were a significant source of inefficiency on early electric locomotives, especially when going faster than the speed at which continuous tractive effort was produced. Efficiency at maximum running speed for the geared locomotives was on the order of 70% vs nearly 90% on the gearless bipolar locomotive built for NYC and the Milw.

I also highly recommend Douglas Self’s website for both the loco locomotives and retrotechnology. The articles on audio are interesting as well.

I wonder how you would class bi-polar electrics?

Can’t get much more direct than that!

I look up the class EP-2 “bipolar” electric on Wikipedia and found that maybe the drive was less direct than you think.

You see, the whole motor was not attached to the axle, only the armature. The axle shaft with its surrounding armature was allowed to bounce up and down in relation to the motor field windings, which were fixed to the truck frame.

The field winding was an older “bipolar” design where the poles were on the horizontal axis, allowing the armature that moved up and down with the flexing of the axle “primary suspension.” You see, with the poles sideways, the armature could move up and down in relation to them without hitting anything.

Clever, huh? The torque was not transmitted mechanically but rather through the magnetic field passing between the truck-frame bipolar armature and the axle-mounted motor armature. Maybe not very mechanically direct in its drive after all.

I wasn’t going to say anything because the terms of the original question ruled out electric drive at all (other than for steam-electrics, and I know of no steam-electric that used jackshaft final drive as the Russian teploparavoz or the Swedish steam turbine did), but Batchelder drive does involve the ‘closest thing to direct drive’ that we have in the electric world. No gears, no shafts, no discs, no links. Of course, no reduction of unsprung mass or reduction of road shock to the armature, and reduction in working efficiency due to compromises with pole configuration and air gap … but here is an interesting demonstration of the principle often quoted for reciprocating steam that operating simplicity and general reliability can trump better nominal performance or higher “thermodynamic efficiency”.

The funny thing is that I distinctly remember one of the Heilmann locomotive style steam-electrics using Batchelder drive (in a four-axle truck) and went so far as to look to see if they might be mentioned in this thread, they were link ‘quill’ drive with armatures concentric with the axles.

Again, guys, electric power doesn’t count in this thread. Even ultimate-simplicity arrangements. The ‘transmission’ is already implicit in the current control and possibility for interruption implicit in all the electrickery before the traction motors. In the thread we even ruled out locomotives with torque-converter drive that don’t have full lockup, and locomotives with clutched transmissions.

On the other hand, my early understanding of the Bowes drive (which turned out to be incorrect on studying some of the preserved material) was that it acted

You were thinking just what I was asking, a hard link. Strange thing is I never even considered that there would be a fluid coupler for these monsters.