Any ideas how to do this? I came into a load of almost new ho brass, hate to not use it. Most will go to tunnels but some I want to blend into ns sections. Is painting an option or is there some chemical that will fade the brass color? I live in Arizona, oxidation is not a concern.

Putting the brass in tunnels and hidden staging would certainly be one use. Otherwise, if you plan to paint the track, using the brass for track that is at near-eye-level, and/or more distant from normal viewing would make the rail tops less obvious.

Another thought, the track cleaning/polishing process “gleeming” discussed in these Forums, puts a mirror finish on the rail tops. I would venture a guess that this process might [^o)] minimize the color difference between brass and nickel silver, but not eliminate it.

One final thought… while I am a strong believer in making do with what I have, my priority is to be happy with the outcome… ‘cause I’m gonna be lookin’ at it for a long time.

Jim

Paint is going to be the easiest way. Not sure about a chemical treatment ever matching, plus it might be toxic.

I would urge a rethinking of your plan to put it in hidden track areas. It’s not just moisture that attacks brass track. There also various air pollutants such as hydrogen sulfide and ozone that play a role. I know AZ has great views, but also that the air is nowhere near as pristine as it was in the early 60s. I’ve been back a couple of times since and it’s an issue, even in the Grand Canyon. Then there are some pending policy changes that may lead to more pollution. Just my [2c]

Brass oxidizes even in dry environments – and the result is non-conductive (unlike nickel silver, its oxidate conducts better). That’s why it needs cleaning more than nickel silver.

Brass track in hard-to-reach places is a bad idea.

It’s no bargain if the trains don’t run well.

I’m with the rest on brass track in hidden areas. I used it on my yard and spur track, because it’s all right in front of me as I operate. I used it because I had a lot of it, along with switches, from various manufactures. All the main line / continuous run track is NS.

Mike.

Prototype steel rail that has been exposed to morning dew for a few days since the last wheels rolled by develops a thin layer of corrosion that looks remarkably like brass. I’ve used my brass at the bumper ends of spurs and single-end yard tracks - places where a locomotive is unlikely to go. I’ve also used some 16 scale meter panels of what had been flex track to decorate an MOW storage yard and load a flat car. The rest is stretched along the ROW, pretending to be replacement continuous welded rail scheduled to go on the already in place concrete ties during the first weekend in October, 1964. (For the reason that will never happen, check my signature.)

A lot of so-called brass rail problems can be minimized by running a John Allen rail cleaning car or two every time you operate. That, plus gleeming the rails, will keep things bright and shiny - and electrically clean.

Chuck (Modeling Central Japan in September, 1964 - TTTO, 24/30)

This ^

There is a reason you came into a load of brass track - someone else was dumping it probably in favor of what works best - NS track. Many years ago when I was a college student I had a little brass track so I just used it on a siding where trains would not be operating much - a siding used to park freight cars. Eventually I put it in the circular file - ie trash can.

BTW, real rail has a silver sheen where the wheels have been polishing it; you won’t be able to totally disguise the yellow color of brass because you have to keep the rail clean and exposed to conduct electricity.

While I feel the same in that I don’t like to throw away “usable” train equipment, all I can recommend is may be use a little of it where you are parking freight cars and engines won’t be using it much and if possible, sell it for a little cash if you can, and use proper NS track where most of the engines will be running. Put the brass track you don’t use on Ebay.

Of all the things I have bought in 45 years in the hobby, the only thing I have disposed of is brass track. I threw it out.

The only way to use it, is on a small layout where all the track is easy to reach. That way you can scrub it with a bright boy every time you want to run trains. The only reason to use it, is to run trains while you save your pennies for nickel silver.

But my recommendation is don’t wait, don’t think about it, just throw it in the trash can now.

Paul

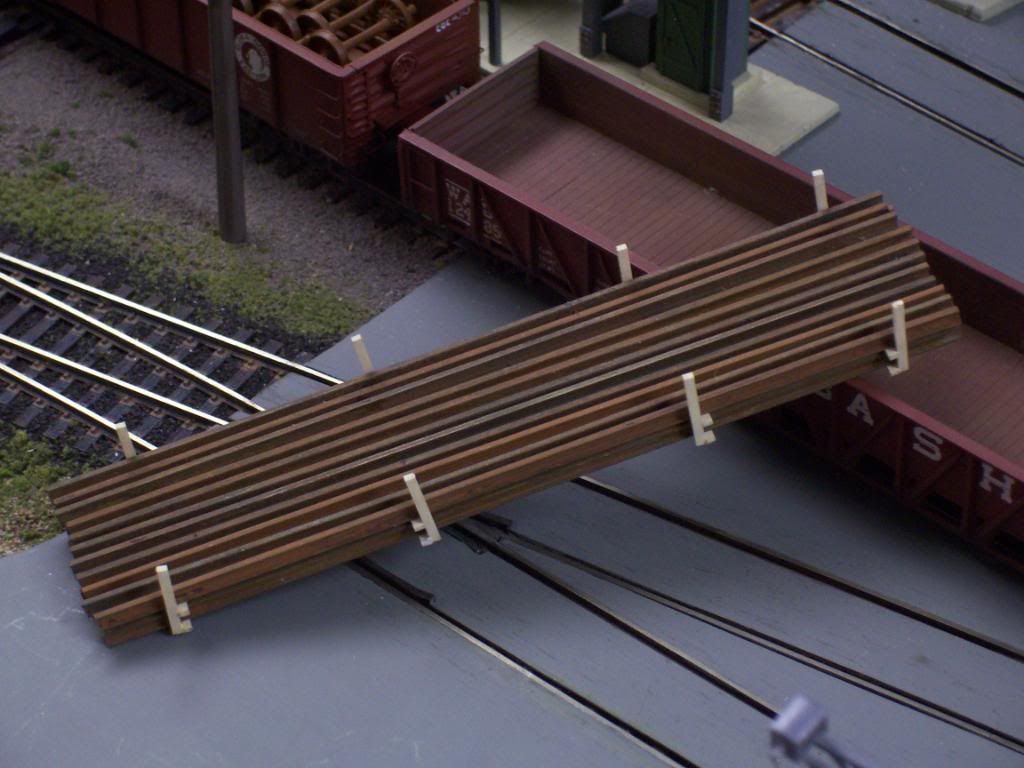

I certainly wouldn’t throw it out, but if you want to use it, cut it into proper lengths (33’ and 39’ were common in the days of stick rail), then paint or blacken it and use it as gondola loads…

…or as lineside details, piled on a couple of old ties…

…or cut it into shorter random lengths and use it as part of a scrap load…

If you’ve got lots of brass rail, take it to a scrap yard…they’ll pay money for it, and even a few bucks is better than having it in a landfill.

Wayne

I don’t understand the statement above! There is No oxygen in Arizona?

The only way to stop oxidation is to put it in a oxygen free room…Make sure You have Your oxygen suit on first though…

http://www.chemguide.co.uk/inorganic/redox/definitions.html

When I was welding…I used all My excess brass track for Brazing, instead of buying brass rods.

Take Care! [:D]

Frank

Plenty oxygen in AZ even at 5000 feet. Sorry I meant the dry air is easier on the brass, so I heard.

Mister Mikado,

Well I don’t know about the yay or nay on the drier air regarding oxidation…but for some one with health problem’s it is supposed to be good!

I had a all brass code 100 Atlas hand laid track two level layout in the basement in the mid to late 50’s and I used Brasso on the the track to clean it and when I first tried doing the track it was a little work intensive, but the results were great and had minimal time in cleaning it after that…really just didn’t care for the color.

Take Care! [:D]

Frank

People who live in places where the weather weenies call 10% humidity ‘high’ consider corrosion as a rumor spread by people from wetter venues. That’s why the Air Force stores mothballed aircraft at Davis-Monthan AFB (Tucson, AZ) and out-of-service civilian aircraft congregate at Mojave, CA.

I have never cleaned my down local freight holding tracks with anything but a shop-vac. Just for grins I put my little block of lead (TTT 0-4-0T #60) at the bumper end of each one and applied power. It ran the yard of brass without a hiccup, and transitioned to nickel silver without any change in speed. It has been several years since I last ‘cleaned’ those rails - with a dry paper towel.

With the prices commanded by scrap metal today it’s worth finding a place that pays for recycled brass. Why throw money away, even if it isn’t much.

Chuck (Modeling Central Japan in September, 1964 - in the Dessicated Desert)

Exactly…That’s why I would use the brass track…If one of the local HO club’s been using brass track since the layout was built back in the early 50s and use nothing but a Athearn dummy F7A with a bright boy attacked to the bottom of the fuel tank why can’t it be used today? Simply put it can be.

Brass track is not a evil thing as many claims.

Well, as it happens I have 99 ft of code 100 NS rail (same density as brass). It weighs 18 ounces. Checking prices on the internet they are around $1.30 a pound. So that makes the scrap value $1.46. That’s 16.5 pieces of flex track or 66 pieces of Atlas straight track (9" sections).

Of course you have to separate it from the ties, drive it there, etc. And some folks pay less if it isn’t clean. So unless you have an awful lot of the stuff, it probably isn’t worth fooling with.

I’m a big pack rat (I think it’s another name for model railroader), but some things just aren’t worth it. Sure save a few pieces to paint as a gondola load or decorations next to a section house, but the rest…

And I know you can run with it - I did so for a few years, but it doesn’t look good and it does need cleaned where I live.

Paul

amen

I too have some leftover brass sectional track from my early days in the hobby ('60s). And I put most of it to use, too!

My HO display cabinet is all brass track. And, I’ve used it in a couple of static displays (i.e. spare rails, scrap metal gon loads, etc.). I also gave a bunch to a neighbor kid years ago to start a layout (never happened).

But, there is no way it will make be used as powered tracks on my layout.

If you have a lot of it, I would just put it up on Ebay or give it to an MR in need.

BTW, I sure wouldn’t put it out of reach (i.e. in a tunnel) as you will soon find it needs to be cleaned more than the nickel silver.

I was given quite a few lengths of brass flex track part way through the construction phase of my current layout. Like Mobilman44, I decided to use it for my storage/display shelves.

With all the naysayers on the value of brass track I have never had a problem with it running straight DC once it was “gleamed.” I live in south Texas with high humidity. I can’t comment on its use with DCC which I suspect is more sensitive to dirty or oxidized track. For all the talk about how bad brass is I have offered to pay shipping for anyone wanting to get rid of it and no one has ever taken me up on it. It also sells quite well on Ebay.

Regardless of the corrosion argument, I never cared for the unrealistic yellow look of brass. Real rail, polished by the passing of trains is silver, not yellow. If that doesn’t bother the OP, then have at it.

I guess those dry climate dwellers can feel sorry for those of us in more humid regions. I’ve lived in both and I never liked humid weather. Where I lived in southern Indiana, at times you could almost cut the air with a knife it was so humid. I run a dehumidifier in the basement to keep it around 50% in the summer; in winter it’s usually well below that here.