How close do you put your track to the layout’s edge,on my new layout on one side it is two inches and some areas it is one inch and three quarters,i like it that way but wondering what others do.

Most people won’t like my answer, but I have one section where I plan on representing " Red Rocks " on the D&H where the tracks are right on the edge of the benchwork.

before

After

So far, after three years, NOTHING has fallen off the tracks in this location even with a 6 yr old at the throttle & numerous kids watching

Gordon

The local modular group has a three and 1/8 inch track centre from the edge but that is to keep curious little fingers away at expositions. Also have a rather tall long double tracked viaduct. As long as the track work and locomotive and rolling stock is all guauged correctly, I don’t see too many problems.( Yes I am well acquainted with Mr. Murphy!!)

Cheers, The Bear.

A little depends on the environment your layout is in. If you have narrow asiles or a low layout, they are more likely to get bumped. If there are children around, little fingers aren’t too careful sometimes. (Ask me how I know.)

Under Videos above, there is one on installing a plexiglass safety fence, under Expert Tips.

I’ve seen another article on it somewhere and plan to install one, as I have a couple of places that are too close to the edge for my liking, even without little hands around.

Also, most folks try to avoid running parallel to the edge for the looks of it, but it is hard not to if you are doing a small layout.

Good luck,

Richard

Generally speaking, my trackage is a minimum of 3" away from the edge of the layout, except in one spot–Yuba Pass, where the trackage is built on a shelf with a sheer drop of six actual feet to the concrete garage floor. 10 years and no accidents. Of course, the speed limit is 25SMPH, so that might have something to do with it, LOL!

Tom

I have one yard track that is 25mm away from the edge of the support structure (22.5mm of subgrade surface and 2.5mm of foamboard fence 25mm above railhead height.) There will also be a layer of Masonite when I get the fascias installed.

As you probably gathered, it’s a staging yard track in the netherworld.

Surface construction is planned to leave at least 50mm between the nearest rail and oblivion unless there’s something solid to prevent inadvertent tumbles into the Tomikawa (Wealth River, virtual watercourse in the aisleway.) Bridge spans will cross watercourses with thick, `Catch ‘em if they fall,’ vegetation at the bottom. They all slope downward toward the Tomikawa, some on truly hairy angles.

Chuck (Modeling mountainous Central Japan in September, 1964)

I have an 1.5" leway to the edge.

I also have a strip of plexiglass as a “bumper” attached to the edge that sticks up about 2.5 inches, so as to prevent trains from taking a 36" nose dive to the floor.

I learned that after one of my beloved Mikes took a “tourist trip” to the floor, taking some RR cars with it!

[8-|]

ECI U Boat 3014 comes around the edge of the river on the East Central Indiana Ho railroad. I have several close to the edge on the railroad, but nothing closer than 2 inches.In fact, I have angled the track slightly inward to prevent falls.

It takes nerves of iron to be a riverboat gambler or a model railroader. But I have seen guys hedge their bets a little in a variety of ways. One common way is to put a clear plexiglass wall at the biggest danger points to prevent disaster. More imaginatively, one guy put in a line of trees but with a difference - the trunks of these trees were actually rather large nails driven into the benchwork.

Dave Nelson

Dave, that’s a clever idea using those “nails” as a hidden guardrail within the foliage.

For our club setting, the Lexan barriers a nec not only for layout protection but can act as a safety net for any of those tracks quite close to the edge.

Inexpensive Plexiglas would work fine a home layout where there would be a min of abuse, however, I perfer 1/8" Lexan. It may cost abit more but it is a far better product. Lexan cuts, drills and secures great w/o any possibility of cracking. If it is flexed it springs back w/o damage. Plexi can break or crack at the mounting screws if this happens.

Thinner rips of the plastic are even used as guardrails in hidden areas as well as scrap 1/4" MDF for tempary sections not sceniced

The Lexan within the tunnel will stay, the outer piece is where scenery is yet to be done.

Lexan protective “shields” along the entire yard.

The Lexan has proved to be quite satisfactory for our needs. The height was figured so we still had easy reach but helping to keep those “little” wandering hands away from the trains during shows. At first, I wasn’t sure that the “flimsey” 1/8" would be stiff enough, but the flex proved to a benefit. Children even adults that would rest or hang on it realized it moved too easily and it only becomes a hand/ finger rest. If too strong these little ones would be doing “chin ups” on it. If this was Plexi, the panel would break @ the mounting screws with one good flex.

I have a few spots where the track is close to the edge, but don’t worry about it too much. If speed limits are obeyed and the operator is paying attention to running the train, there’s little danger. Your trackwork, of course, should be pretty good.

This one is just a siding, with slow speeds and usually just a car or two. This looks to be on an especially busy day, with a train parked on it “in the clear”.

The track around the turntable, at the extreme left side of the photo, is very close to the edge, but also a siding, so low speed and an attentive operator is again necessary:

Wayne

I intend to have my outer main running quite close to the edge on a convex curve along my yard module. I will use something to keep the trains from falling…not sure what at the moment, but there will be a fence of at least 1/4" MDF strips high enough to keep all but the most single-minded of errant locomotives from tumbling over it and onto the floor.

Crandell

LIONS tend to run close to the edge. Here a string of R-17 arrives at the 14th Street platform.

Let me attest to you that the Third Rail does not keep trains from falling overboard, but will prevent a derail from getting any worse.

Train Overboard:

I have found that it’s not only derailments that one must worry about, but the bellies of “Plus-size” model railroaders. I try for 3" minimum on my designs to track centers on N and HO layouts. If it’s less than that, some sort of shield or guard is recommended.

Thanks everybody,think i will stick to one and three quarters.

I would have foam rubber on the floor right under it

Running a ceiling train, I now (voice of experience) make sure that the entire layout always has some sort of ‘fence’ alongside of it, whether this is a row of trees, rocks, iron posts, etc. This is far better than watching a beloved consist fall 600 scale feet to the floor below…As Dave’s friend did, my ‘iron posts’ (from the Christmas ‘Villages’ set) are supported internally by steel bolts which I found meshed neatly with the scale chain connecting them, effectively producing an impenetrable barrier.

That’s too close in my experience. A derailment can easily send an expensive locomotive to the ground.

I never get closer than 4 inches from the edge. That leaves room for error (i.e., derailments). Plus, it ensures that the track is clear of the 2x4 support below the surface so that I can install Tortoises where needed.

Rich

Hi!

This is an interesting topic - and brought out some really neat layout pictures.

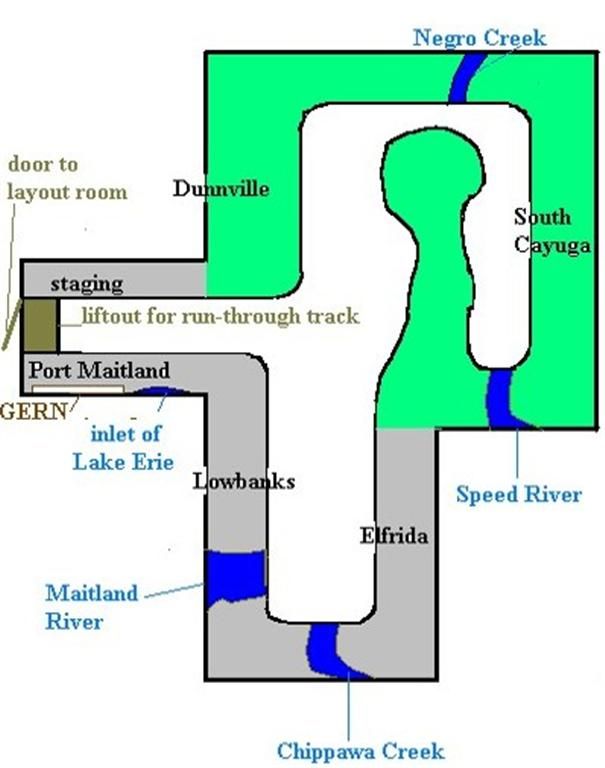

As my layout fills a room with a “hole” in the middle, most all of my trackage is near the outside wall or otherwise “safe” on the layout. The one exception is the mains running across the 4 ft duckunder you meet when you open the door to the room.

On the duckunder, the outside rail (closest to oblivion) is 2 inches away from the edge. Given its tangent track, I wouldn’t expect a problem there that would cause a fall. However, for cosmetics and a bit of added safety, I plan on putting in a piece of trim that would add a 1/4 inch lip to the edge.

But I have to say, the thought of a $300 BLI loco shooting off a 4 ft (close to 400 scale feet) cliff to the carpet below is just mind numbing…

I would probably be upset if something dropped to the concrete floor, but such risks add impetus to make the trackwork and equipment as trouble-free as possible. This pays off in smooth, trouble-free operation and ease of maintenance, too.

I’ve had only two major derailments in the 20-or-so years the layout has been in use. The first was caused when a freight car’s wheels became jammed between the rail and guardrail on the high bridge shown below. That car fell (it’s out of sight to the left in the photo) along with the four shown, while the back end of the train, probably about 50 cars, sat where it stopped despite the 2.5% grade (only about 15 cars were on the actual grade, although the back end of the train was also on a similar grade, separated by about 15’ of level track).

The front end of the train, four locos and about 15 cars, stayed on the track as well - a good thing, as there’s a drop, on both sides of the track, of about four and a half feet.

The damaged sustained was minimal, with an end broken off one car’s roofwalk, a door knocked from another car and a few cars with paint chipped from their metal grab irons.

The other incident involved a dumb mistaken by an operator who shall remain nameless. I, I mean he, was doing some switching the South Cayuga area, shown in the layout room diagram below.

Every time the train moved, it sounded as if there were another train moving somewhere, but a cursory investigation showed nothing out of place (the layout is DC control, with the ability to kill power to tracks where locomotives might be stored or temporarily parked, such as