Well, well. Looky here:

And this has a look of GM to me:

Ed

Well, well. Looky here:

And this has a look of GM to me:

Ed

Yup, bottom one looks like a pair of 16-278’s.

–Randy

Hello all,

In Porsche and Subaru too!

Hope this helps.

I saw an H12-44 pull 150 cars out of the SP’s bowl yard in Santa Clara, Ca. It was not going very fast, maybe 4 MPH and smoking like an ALCO, but it pulled them out. They were switched onto the east bay line. When the Santa Clara tower operator realigned the switchs it pushed those cars back into the bowl. Those oposed piston engines could really put out the power. This thing only had 1200HP.

.

The “boxer” engine is not an opposed piston, dual crankshaft, design like Fairbanks Morse used in their locomotive engines.

.

The “boxer” design is basically a V4 engine with a 180 degree V angle.

.

-Kevin

.

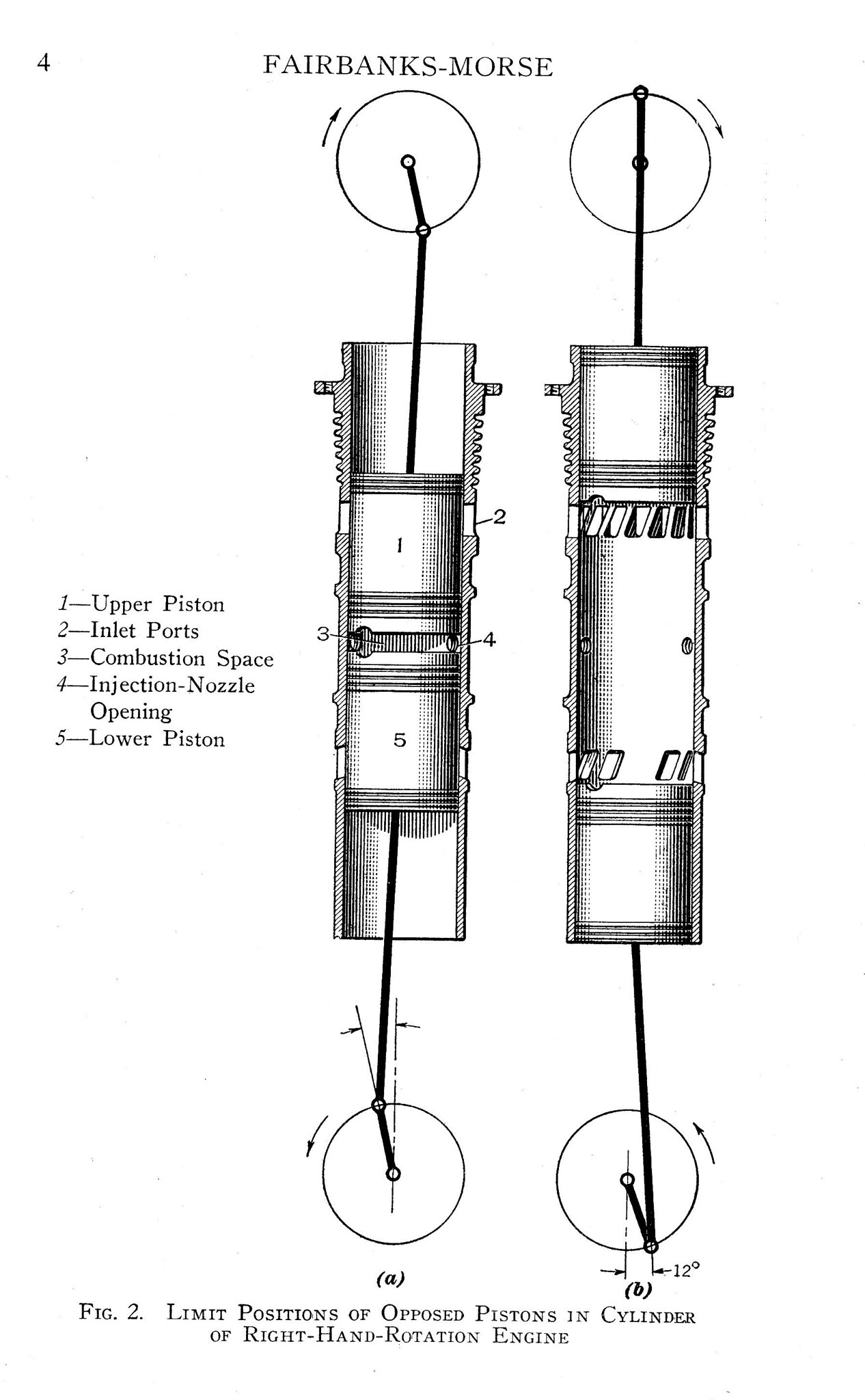

Yeah Ed straightened me out in his Xmas eve post. However reading the sub post, I’m still not sure how it really works…do the pistons travel toward each other on the compression stroke or do they alternate back and forth?

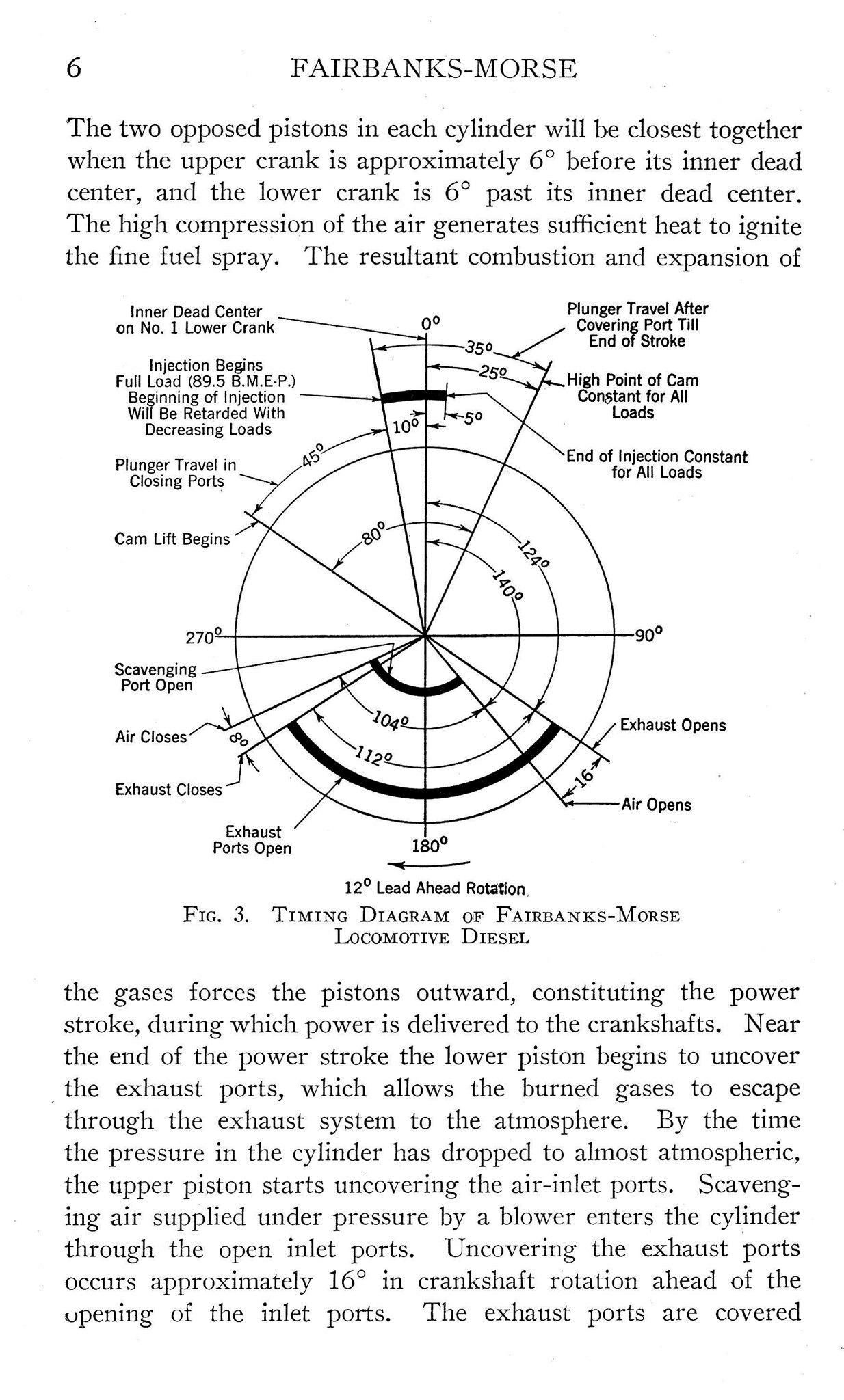

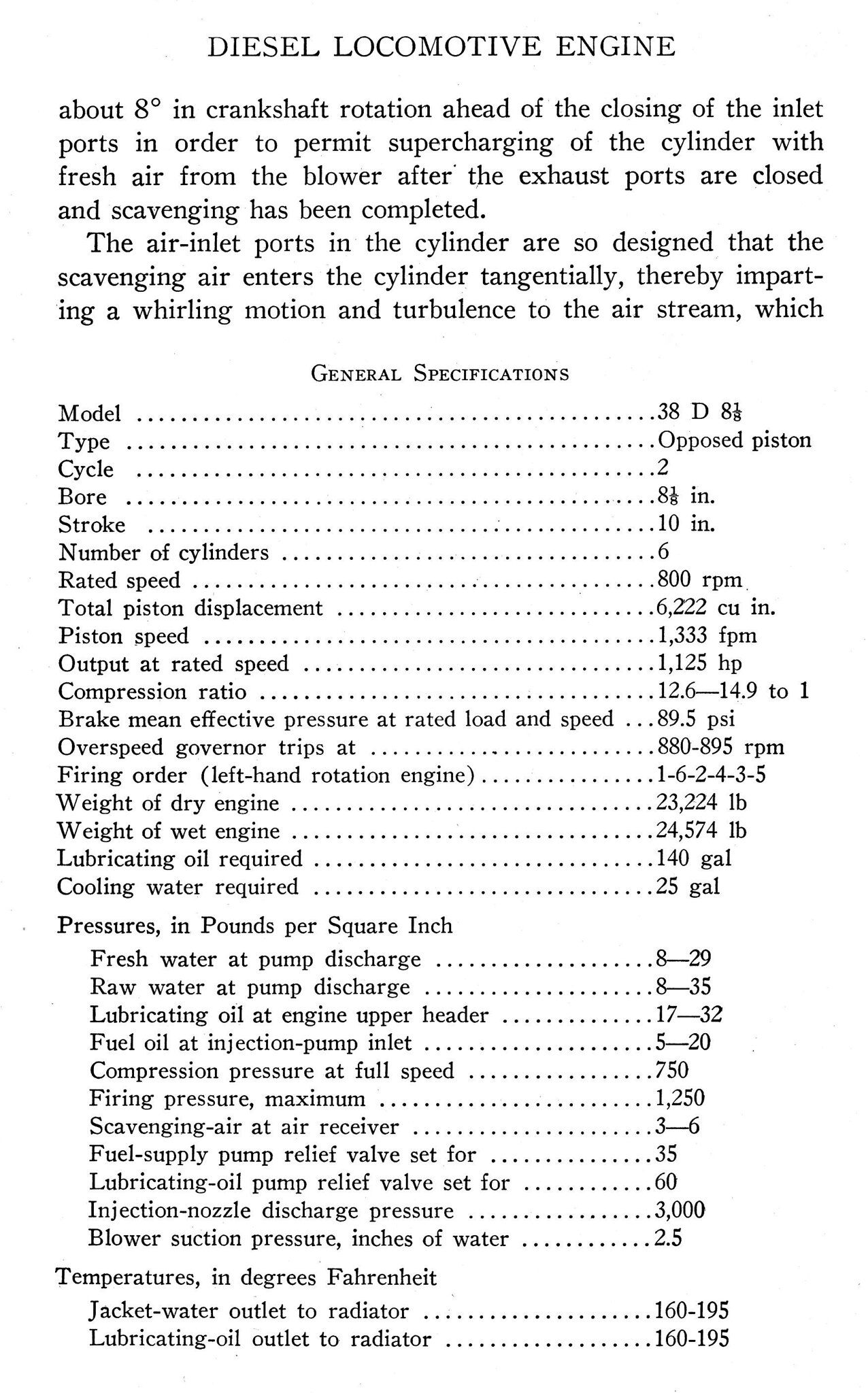

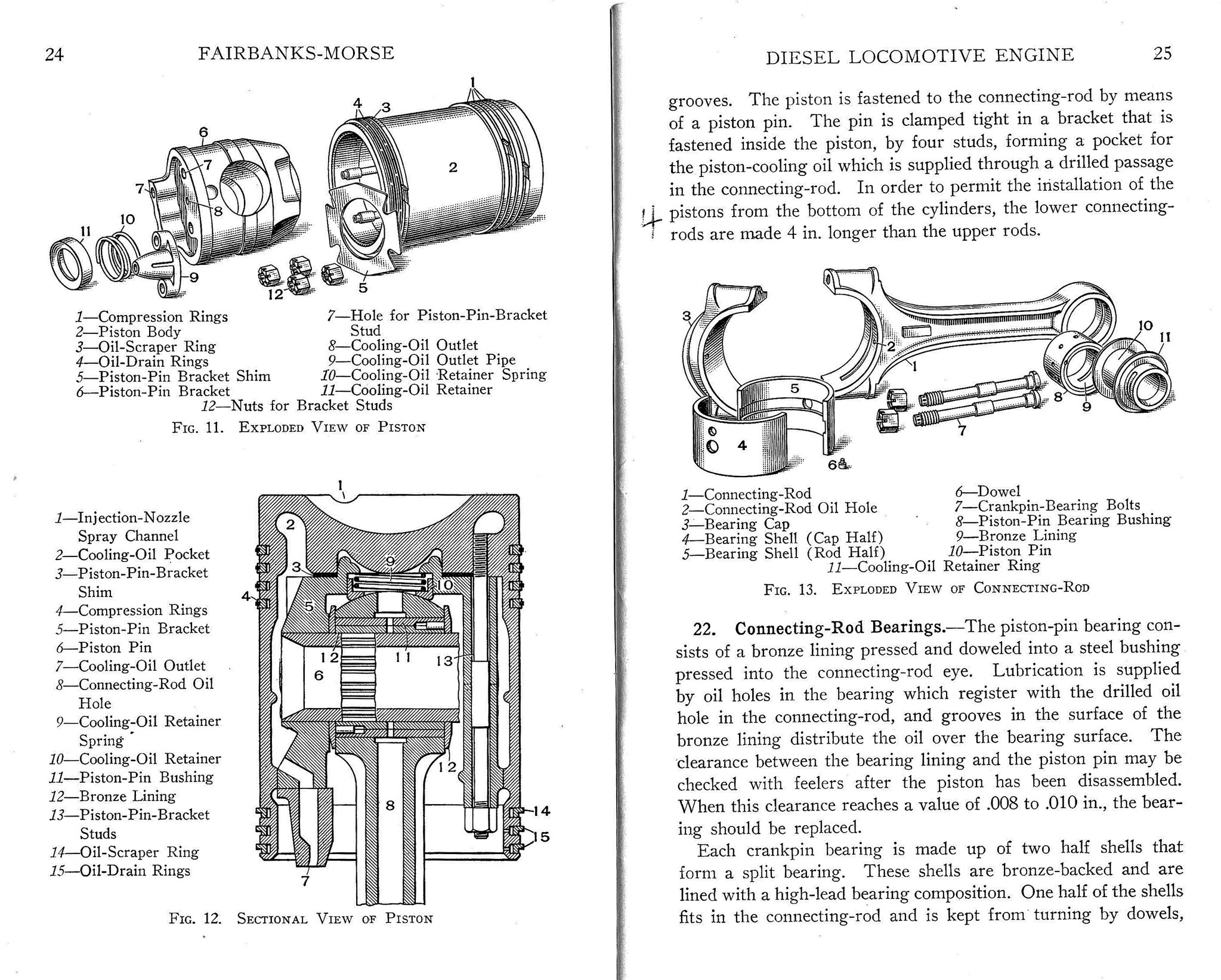

Here’s a few interesting tidbits from an ICS book in my collection:

FM_OP_0001 by Edmund, on Flickr

FM_OP_0001 by Edmund, on Flickr

FM_OP_0002 by Edmund, on Flickr

FM_OP_0002 by Edmund, on Flickr

FM_OP_0003 by Edmund, on Flickr

FM_OP_0003 by Edmund, on Flickr

An interesting note that I didn’t realise was the clearance between piston heads is only 115 to 135 thousandths. No room for carbon buildup there!

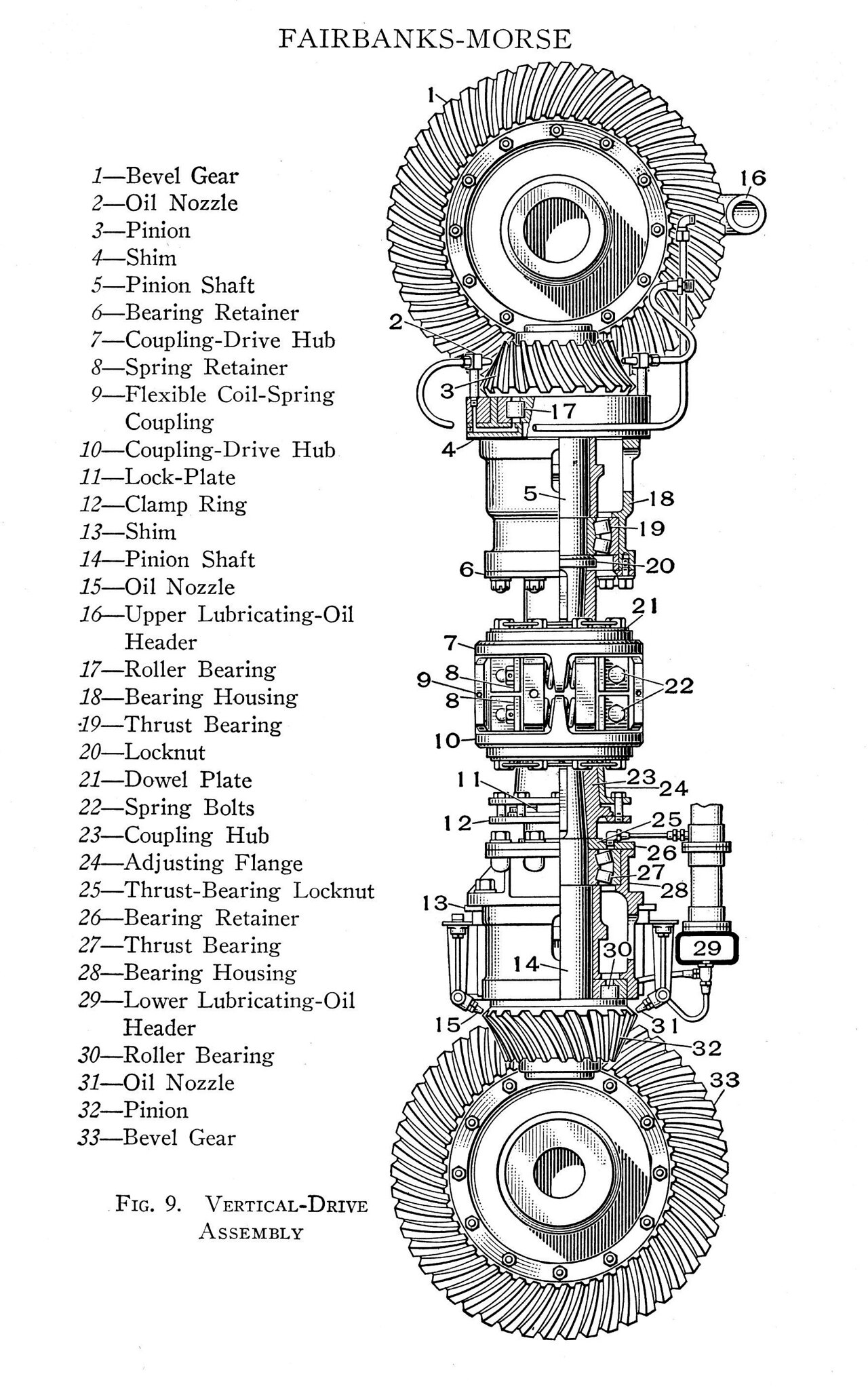

Here’s the vertical drive that links the two crank shafts together:

FM_OP_0004 by Edmund, on Flickr

FM_OP_0004 by Edmund, on Flickr

An amazing piece of machinery!

Cheers, Ed

Other Ed’s post (above) is a great read.

But, to the chase, the pistons in an opposed piston engine travel toward each other on compression. Really, if you look at it, they HAVE to. If they didn’t, there’d be no compression. And…

Ed

One more informative page to the point:

OP_FM_0002 by Edmund, on Flickr

OP_FM_0002 by Edmund, on Flickr

I have several more pages of the booklet scanned and viewable here:

https://www.flickr.com/photos/102225238@N06/albums/72157689157947401/with/45568488095/

I still have to do some sorting of the pages but there is more text that will “fill in the blanks” so to speak.

Regards, Ed

Fascinating…

.

This is the only inline six cylinder engine I know of where the firing order is not one of the following…

.

1-5-3-6-2-4 (99%)

1-4-2-6-3-5 (1%)

.

I had no idea… I am always amazed at how much there is to learn.

.

-Kevin

.

Funny I should see this – I just bot some F-M models and was reading up on them.

The April 1987 issue of Trains Magazine has an article called “Train Master triumph, Speed Merchant flop, OP paradox”, the second part of a two-part article written by Robert Aldag, who joined F-M in 1946 as a sales engineer and ended up heading the sales department until they quit the biz in 1961.

In this article, he goes into great detail about the problems the OPs faced in railroad service, and why they did so much better in navy ships. Among the issues:

Higher power demands in railroad service than in marine service

Engines operating at peak power for longer (think of a loco slogging up a hill, with a heavy demand for torque at maximum engine speeds)

Navy engines operated on the sea, with a supply of cool, dense air; railroad engines had to deal with higher air temps, lower pressure and lower humidity

Lower pistons dealt with excessive heat, as the exhaust ports were at the lower end of the engine, so they didn’t get the same cooling benefits from intake air as the upper pistons. The lower pistons would fail, often damaging the liners and sometimes setting off a crankcase explosion.

Dirt! Working out on the plains, FM locomotive engines injested all sorts of dirt and grit that the Navy engines didn’t have to deal with.

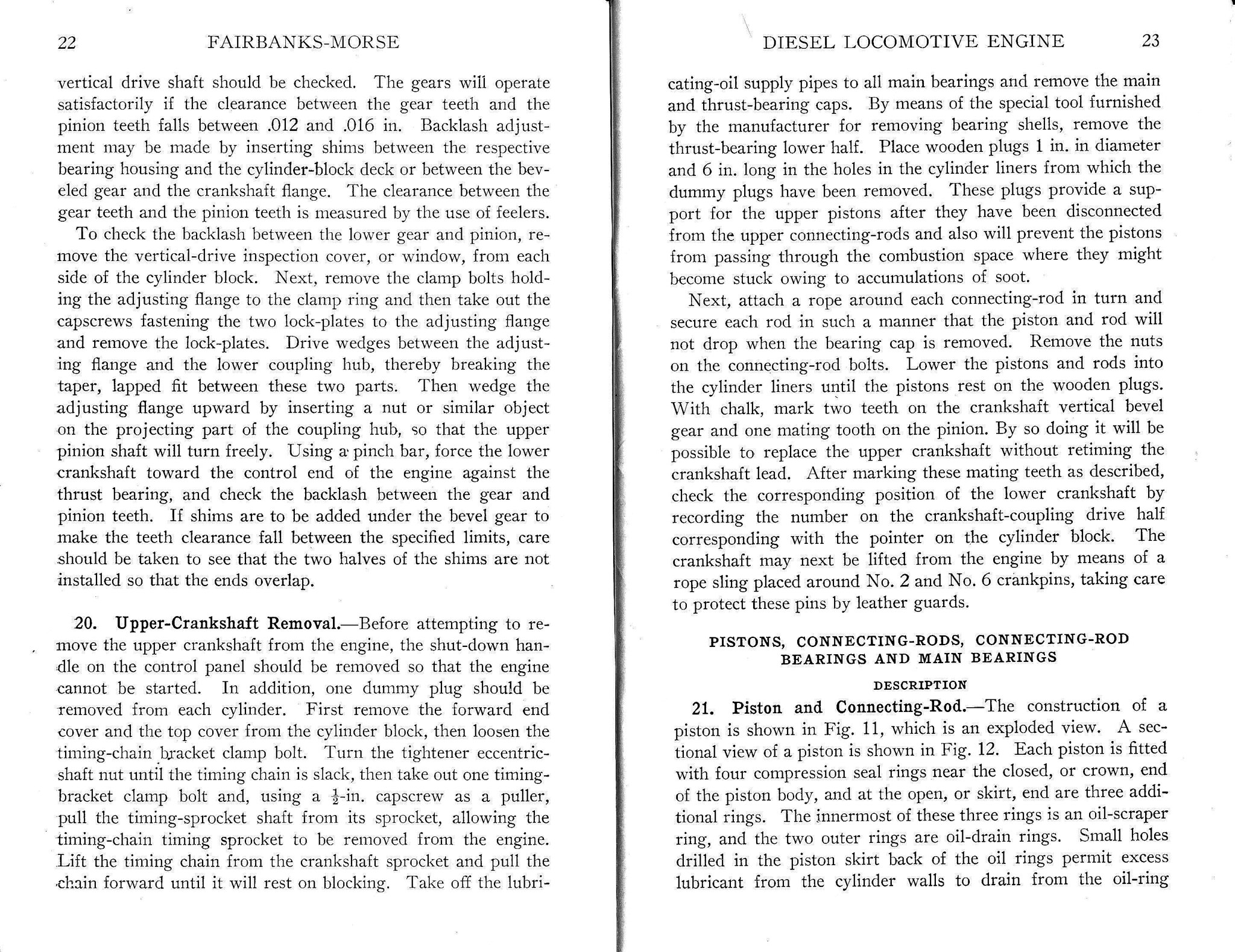

When a lower piston or liner failed, changing out the power assembly required removing the upper main bearing caps, crankshaft, rods and pistons – all of them, even if only one piston went bad. The locomotive had to go under a crane. IIRC, changing a power assembly from a traditional engine is a much simpler job.

I highly recommend this article, along with Part 1 (March '87), which talks about the business challenges faced by F-M: The Beloit strike that allowed EMD Es and Alco PAs to get a foothold before the Eries could be delivered; the high cost of building the units; the early road failures experienced

In comparison to an EMD or Alco maintainace for this reason was much more extensive and took about three times as long from one book I read. A lot of railroads concentrated the FM in one area because of the specialized maintainance needs. Rio grande concentrated them in Salt Lake City for example. Jim

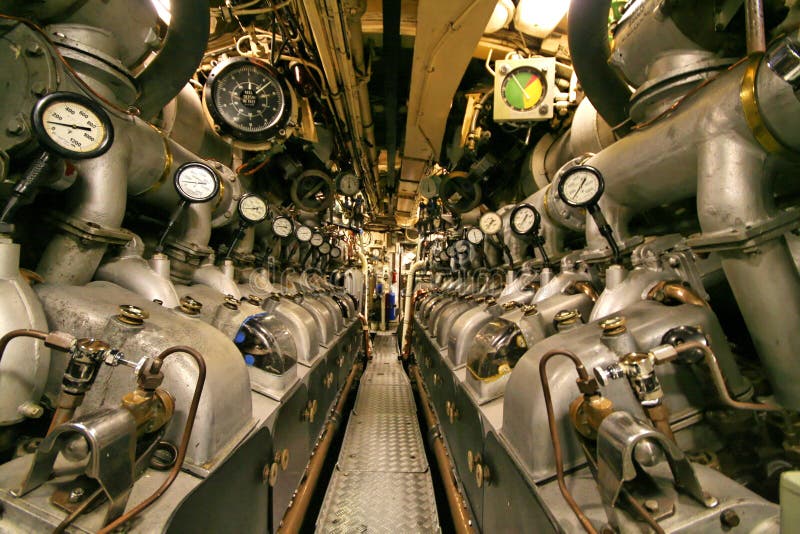

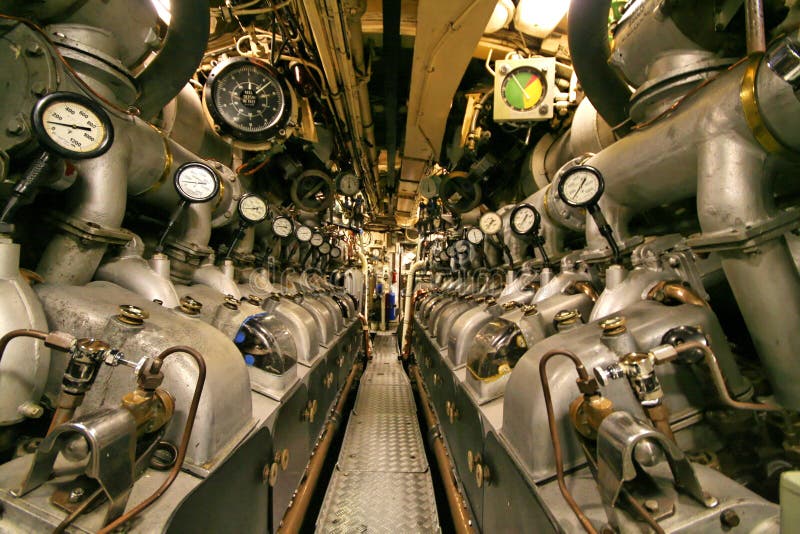

Please examine the picture of the F-M diesel being installed in the submarine that I posted earlier.

Just how did that engine “go under a crane”, since the engine looks to have been permanently installed inside the shell of the sub.

Am I missing something?

Ed

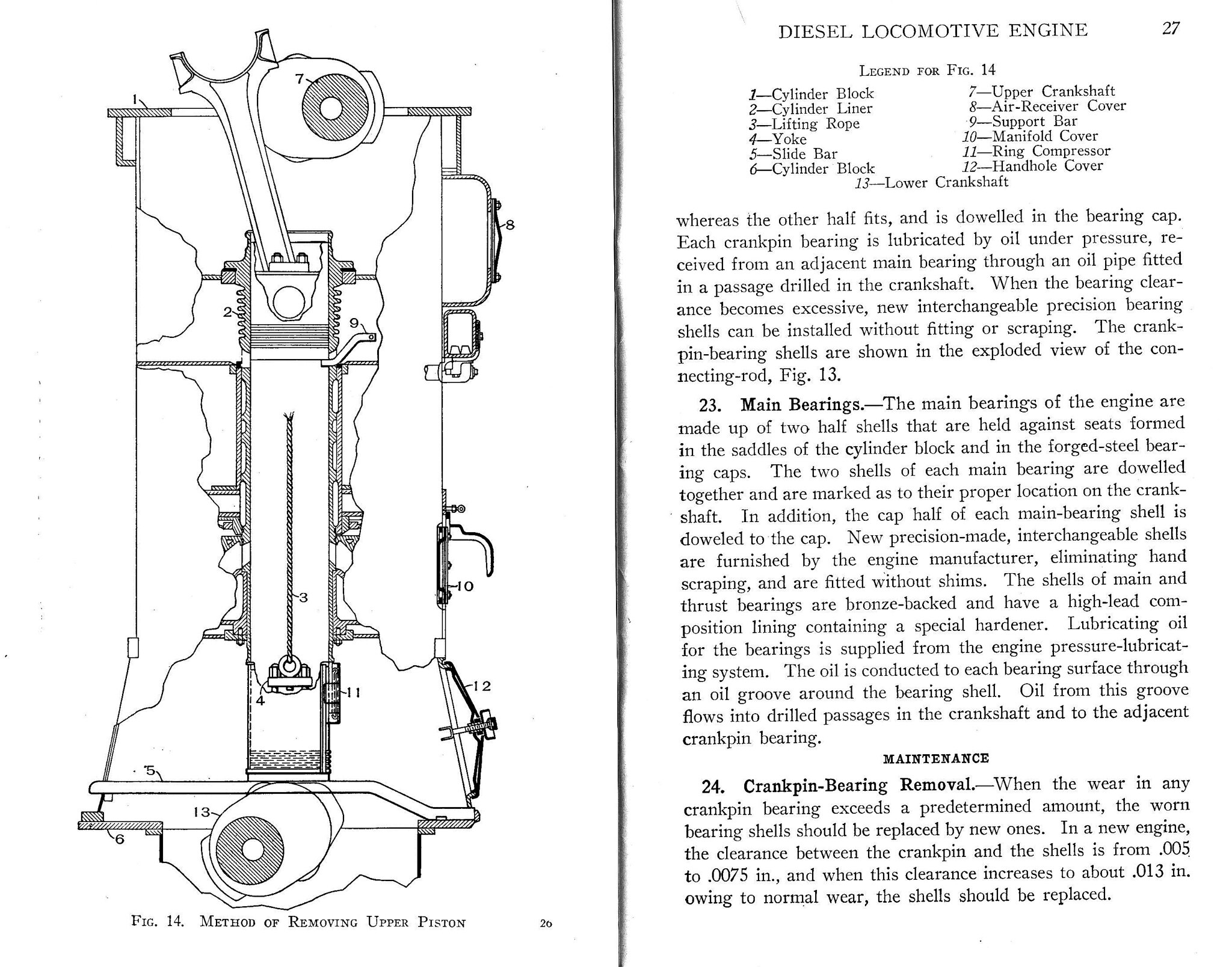

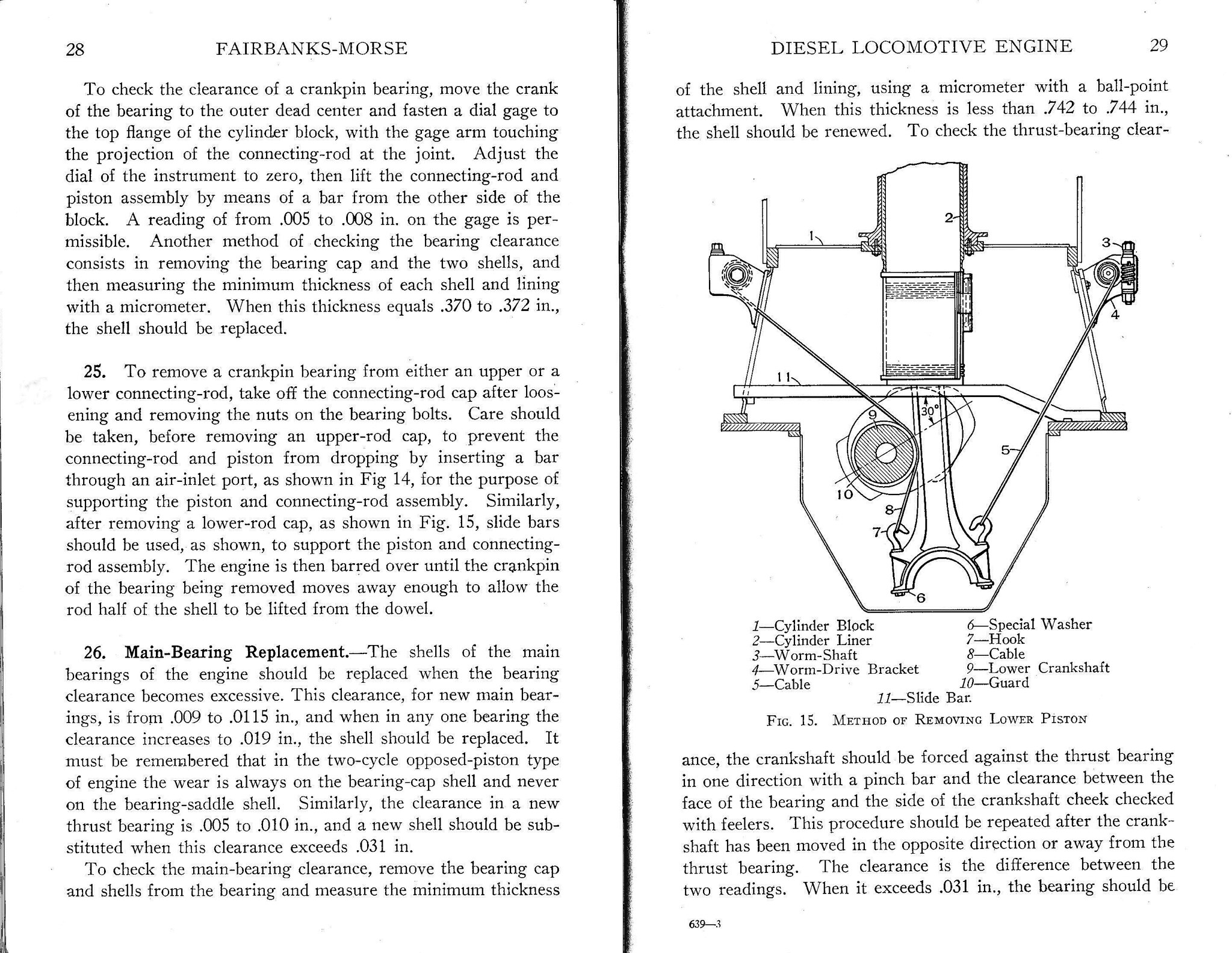

Here’s a couple of pages describing the fun of removing the pistons. A relaxing way to spend the day [:-^]

IMG_FMOP-1 by Edmund, on Flickr

IMG_FMOP-1 by Edmund, on Flickr

IMG_FMOP_Z by Edmund, on Flickr

IMG_FMOP_Z by Edmund, on Flickr

IMG_FMOP-3 by Edmund, on Flickr

IMG_FMOP-3 by Edmund, on Flickr

IMG_FMOP-2 by Edmund, on Flickr

IMG_FMOP-2 by Edmund, on Flickr

Add to this the previous diagram of the vertical connecting shaft and timing chain and you can see where an F-M mechanic earned his or her wage.

The Life Like Erie-Builts and C-Liners are some pretty decent locomotives in HO. They can still be found at auction sites and train shows for a reasonable price. Plenty of room for a decoder and speakers in there, too[Y]

NYC_Erieblt by Edmund, on Flickr

NYC_Erieblt by Edmund, on Flickr

Cheers, Ed

Only thing you might be missing Ed, is that in marine service there was a far less likelyhood of such failure happening. Better cooling, more coontrolled conditioons, cleaner intake air - and running full poower for extended times was strictly reserved for emergencies. Few if any ships would ever routinely run at all out maximum speed under normal operations. There are usually two top speeds - top speed the engines can handle for any amount of time, and the REAL top speed after which you may or may not have an engine left. AIrcraft engines, civilian and military, operate in a similar manner.

–Randy

Quite true. In addition, the guys on the failed F-M locomotive get to climb down, smell the fresh air, and stroll around until someone comes out to pick them up and take them home. That ain’t happening in wartime sub service. Kinda inspires high quality on-board maintenance.

Also, there were four engines in most American subs. Mighty handy, having four…

Ed

Good point - also Navy maintenance was probably a lot better - as in getting done on schedule EVERY time, the only possible exception being some emergency condition preventing an engine from being shut down for scheduled checks.

–Randy

I can’t speak for the submarines, Ed; I was talking about the locomotives. ![]() The crane thing is a direct quote from the article.

The crane thing is a direct quote from the article.

Here’s the passage:

“The problem was that to change a power assembly–that is, to replace a cylinder liner and its two pistons–it was necesasry to remove the upper crankshaft, To do that, the maintenance people had first to move the locomotive so that it was under an overhead crane, Next they had to remov the roof hatch, and then they could proceed to remove the entire upper crankcase of the OP engine. After that, the mechanics could then remove all of the main bearing caps, all of the connecting rod caps and the camshaft drive chain, and then htey were ready to lift the crankshaft out of the engine. Having done all of that, they were then ready to begin to remove one or more power assemblies and install the new ones. And then they faced reassembling all that they’d disassembled.”

Sounds like a fun few days at work. ![]()

From the Aldag article, it sounds like the locomotive versions were tuned for more power. He cites BMEP (Brake Mean Effective Pressure, a measure I don’t understand 100% for comparison. He says the navy-service OPs were running at a BMEP of abotu 85 psi, while the 10-cyl OPs in the Erie Builts were running at 95.2 psi, an 11.8% increase. For comparison, he cites the BMEPs of the EMD 567 in the E7 (77psi), FT (77.9) and F3 (86.6). He mentiones that the 567C of 1954 finally approached the BMEP of the Erie’s OP, but that was nearly a decade and a lot of R&D later.