Hello Everyone, Has anyone built N Scale turnouts and track with the Fast Tracks templates? How good are they compared to the commercial off the shelf track & turnouts? Do you build the straight track or use off the shelf flex track with the Fast Track turnouts? Any thoughts or insite would be helpful! Thanks.

Do yourself a huge favour and go to their website: Fast Tracks - Helping the World Build Better Railroads (handlaidtrack.com)

Watch their videos and your questions will be answered at source.

FWIW, I built several of their Code 100 #8 standard turnouts and two of their #6 double-slips. They’re considerably better than the commercial ones, especially at the frog. If you have good eyes and hands, you shouldn’t have any trouble with N scale products.

There is a learning curve, but by the second or third turnout you’re away to the races.

BTW, after building several turnouts, I knew instinctively that I could build others of a custom nature…and I have. It’s a great system.

This is an interesting question.

Can Fast Track turnouts blend in easily with Atlas Track, or are you committing to hand-laying everything?

-Kevin

This is a Fast Track Code 100 #6 double-slip in an Atlas Code 100 yard:

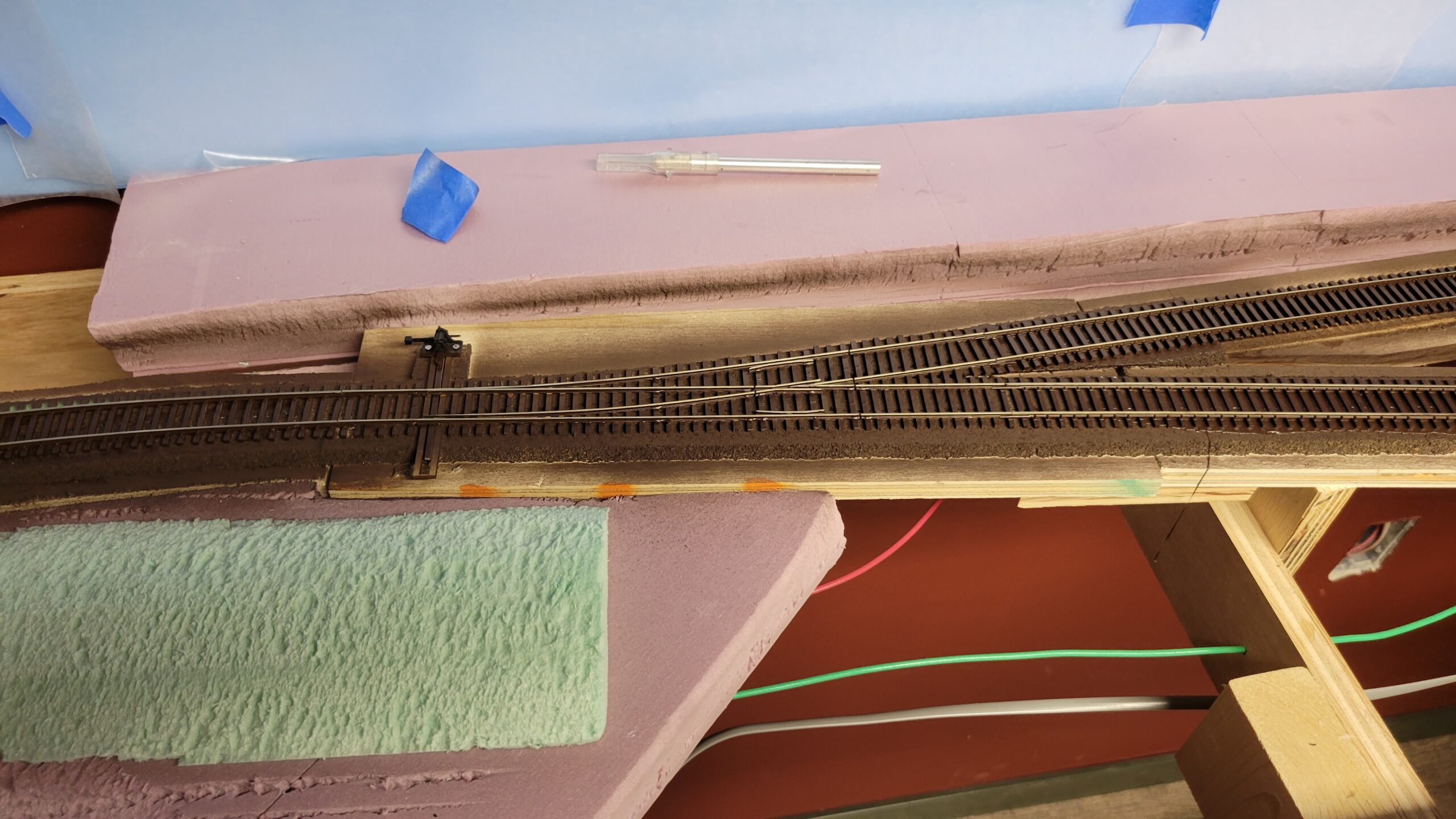

A Fast Tracks #8 Code 100 in my Code 100 Atlas main:

In HO, I build Fast Tracks code 83 #6 turnouts and they mate easily with Atlas code 83 flextrack. For example (straight route is code 83. Diverging route is Peco code 70) …

Before painting the track:

After painting:

Pruitt - what process and product did you use to paint your FastTrack turnouts? The look great.

Dan

I’ve built about 70 N scale turnouts using ME c55 rail. I then use ME c55 flex track for my trackwork. I think Fast Tracks uses ME as their default rail, but you could have a jig made up with Atlas rail if you wanted, it would just take a bit longer since it would need to be custom made. The jigs are awesome (I have a #6 and a #8). Once I got the hang of it, I used their paper templates to make wyes and curved turnouts. The track work is very smooth I really like the looks of it, and it’s not even painted yet! Since I work in N scale, the Opti-Visor has also been a good investment. Learning to build your own turnouts has also lead me to be much better at trouble shooting, as know I know what the critical parts of a turnout are, and how they affect performance.

Scott

I built the entire UPRR Geneva Subdivision with code 55 Fastracks turnouts, #8s and #10s. They take a while to build but are worth the extra time. I ended up with 135 total turnouts on the layout. The turnouts are far superior to any ready made turnout for the combination of prototypical looks and realiable operation. I am now building an HO layout with Fastracks turnouts.

Highly recommended.

Daryl Kruse

Dan, it was a very precise (not!) and involved (not!) process:

Step 1 - Put wax paper over the backdrop

Step 2 - Wrap the ground throw with blue painter’s tape

Step 3 - Shake the can of Rustoleum thoroughly

Step 4 - Spray it all over the track from a couple different directions

Step 5 - Clean the rail tops using a single edge razor blade, then a brite boy.

The most difficult part was installing ties under the rail joiners, but that’s not really part of the painting process.

Thanks for the compliment, by the way.