I am using HO Scale plastic brick sheeting from Micromark. The model I am building requires a couple of sheets placed side by side and therefore there is a seam visible (yes, a very small seam) where the two sheets touch. I’m looking for advice on how to fill in the gap with a paintable material. Placing an overlay of some type over the gap (such as a column) is out at the prototype has no such feature - just a straight wall of bricks.

Thanks in advance

I know you said “no overlay” but just because the prototype doesn’t have something in that spot doesn’t mean your model can’t. What about a downspout? Or an ivy plant growing up the wall? Or some other viney plant hanging down?

If you are still intent on hiding the seam, try some Squadron filler putty, probably the white which is said to be finer (less gritty) than the green. Apply it sparingly, allow it to dry and it is then sandable and paintable. To hide brick seam you may need to carve it a bit once it is dry.

Good luck.

Has the model already been built? The best way to treat such problems is to plan for them before starting the project.

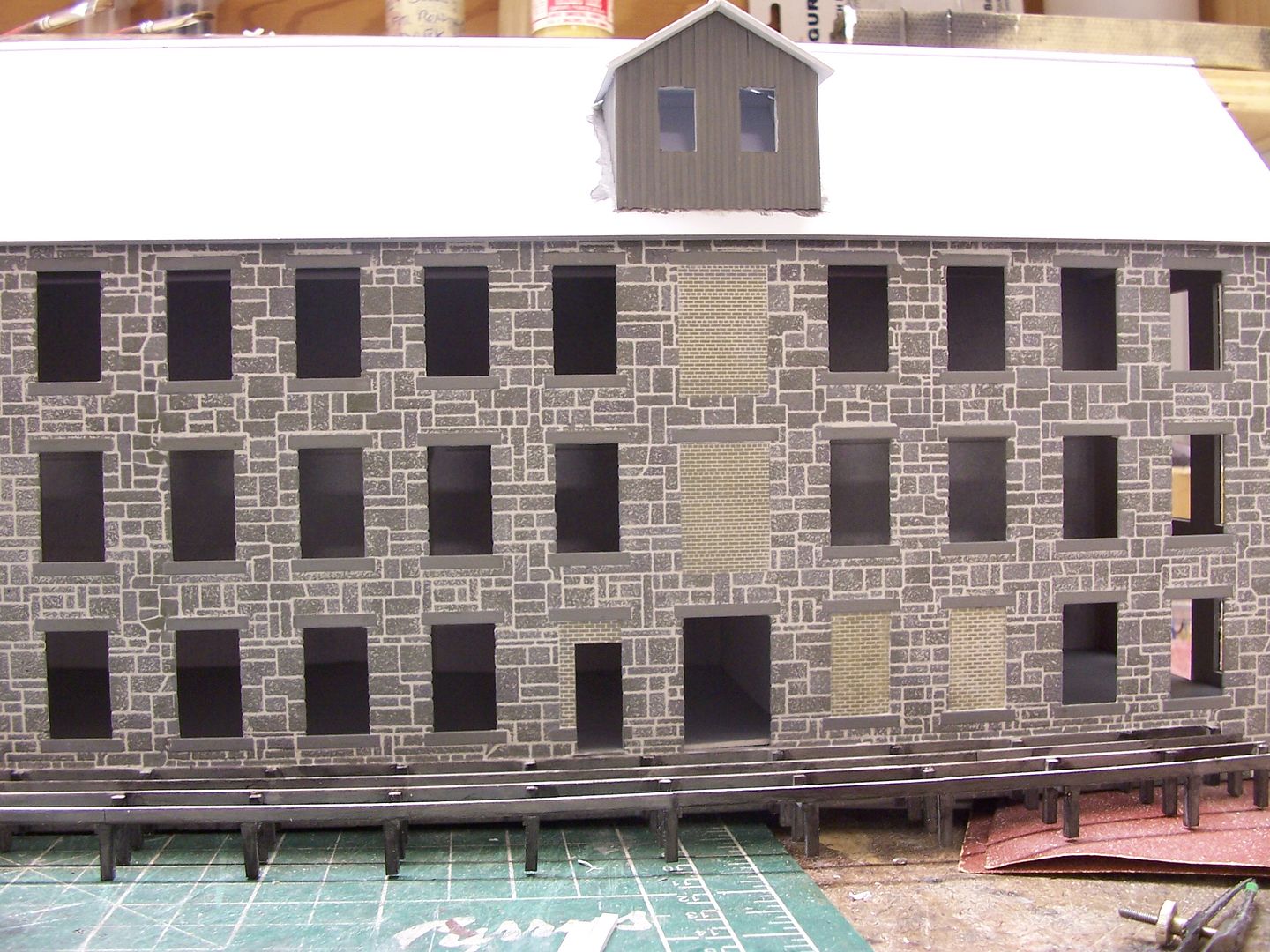

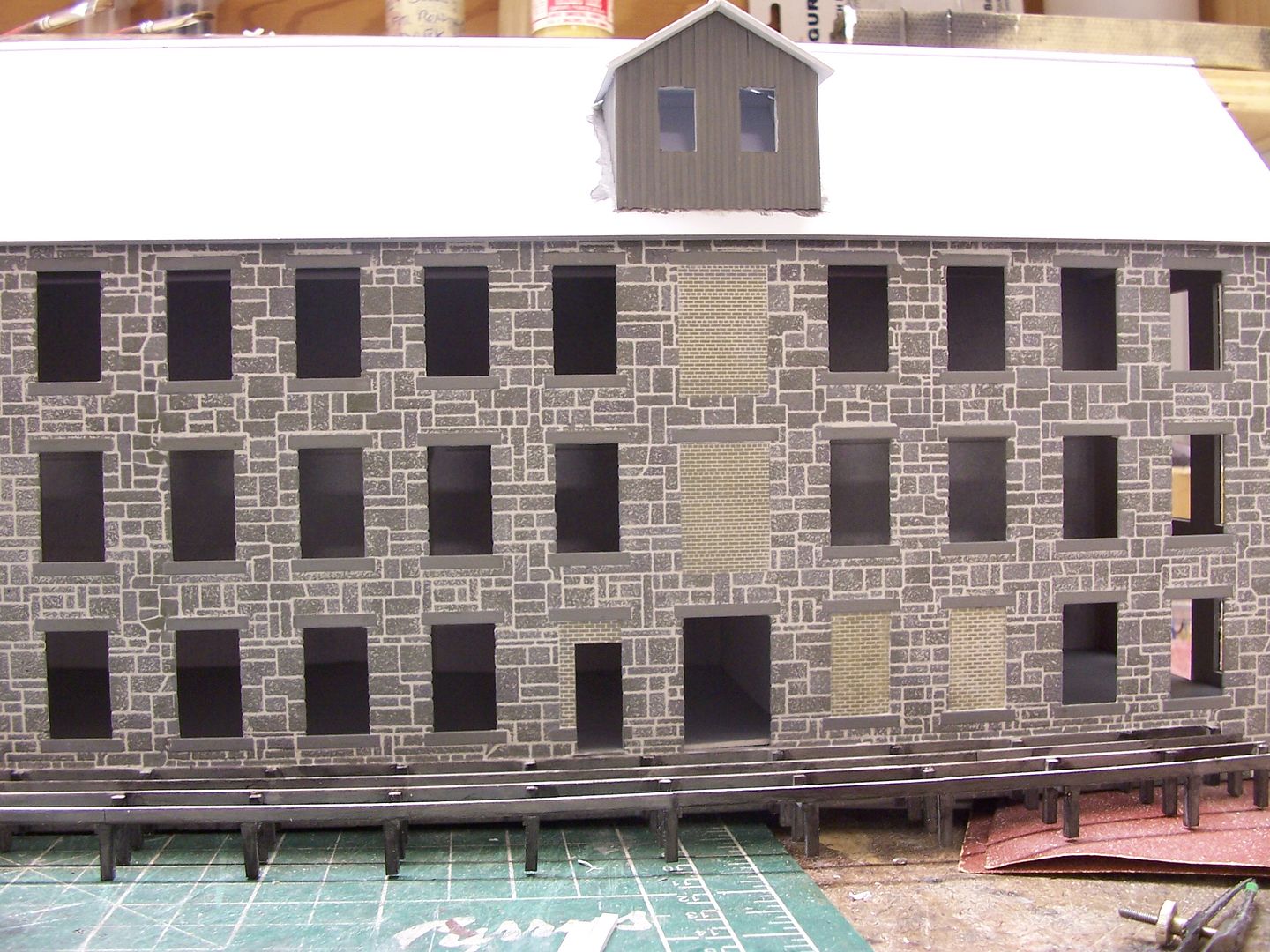

The structure shown below was made by combining one long wall of the kit with its counterpart, which would have been on the unseen (rear) side of the building when placed on the layout. I had to “adjust” the wall length of both mating pieces (the length would have placed the windows farther apart than those on the rest of the wall), then re-do the mortar lines to hide the joint.

The joint is between the windows at the left edge and the ones immediately to the right of them:

Your brick sheets don’t have the issue of window spacing, but the sheets should be trimmed, prior to application, along the vertical mortar lines so that the edge of one sheet, counting from either the top or bottom, shows alternately a full brick/half brick/full brick etc., and the mating sheet’s bricks at the edge should be a mirror image of that.

In other words, when the two sheets are applied, butting tightly to one another, the full bricks will be separated by a vertical mortar line and the half bricks will appear as single bricks, albeit with a slight irregularity detectable at their meeting point.

If your brick sheets are styrene, coating the mating edges with solvent-type cement and forcibly pressing them together during application will help to minimise those irregularities. The plastic will ooze-up between the joint, but resist the temptation to touch it until the material has fully hardened - preferably overnight. It can then be trimmed off using a sharp chisel-type X-Acto blade.

To completely hide the irregularities on my structure, I dipped a piece of the trimmed-off wall material in solvent cement, then rubbed it into the appropriate areas, dipping and rubbing repeatedly as required. Since the filler is th

I’d sure love to see how your project comes along. Because, as others have said, mating two sheets of textured materials can be very tricky, especially small brick. It seems like sometimes, regardless of how careful I was, I could never perfectly hide a seam. Even with filing, sanding, filling, trimming, etc.

Of course, much of how it looks depends on exactly what you want. If you want a very large area of plain brick wall it will be the most difficult. If you can add something to help cover it (downspouts, ivy, signs, weathering, etc.), as others have mentioned, then it should make things much easier.

I would second what Doctorwayne said about trying to join the sections together with solvent, if possible. I think that would make it easier than introducing a different filler material. Also, I have found that, if you try to join two sections of brick material together and make your cuts on the mortar lines, that even being off even a couple thousandths of an inch will change the width of the mortar line and make the joint noticeable.

Not trying to scare you. It’s just as Wayne said, it takes time and there isn’t one really good way to get sheets to match perfectly.

Jim