I’m building a new layout extension with 2 inch foam mounted on 1/4 inch luan plywood. I’ve used Atlas under mounted switch machines before, but how do I do this on foam? Extend the pins? The same question applies to Tortise machines. I was thinking of carving a little pit under the turnouts and droping the Atlas machines in the pit and gluing them to the bottom of the turnout. Anyone ever try this? Sounds like it would work although I’d also have to cut the cork roadbed to provide access to the machine. By the way, I’ve used double sided foam tape to mount Atlas machines on plywood for years with no problems. Thanks, Abbie

I’ve got one turnout with an Atlas under-table glued to the bottom, and recessed into the roadbed and foam. Time will tell if this works. I just got around to gluing the track down a couple of weeks ago, but I did have it pinned down for a couple of months before that. So far, so good, but I’m concerned that I’ll have to rip everything up if the machine ever fails.

I don’t think extending the pin on the Atlas will work very well. It’s already an inch long, but for foam plus roadbed you’d need 2 1/2 inches, and I think there will be too much flex in the linkage for that to work well.

Once I decided I didn’t like the looks of the Atlas switch machines, I’ve been buying Peco turnouts and switch machines for all my new turnouts.

Thanks for the insights. But even if you use the PECO under switch motors you’ll run the risk of having to pull up the track if something goes wrong with the motor - right? Or are you mounting them under the foam so you can get at them from under the layout? Abbie

I mounted my Tortoises on small squares of perfboard fromt he top. I don;t solder the rail joiners for turnouts, so removal is easy enough - just slide back the joiners and I can lift the whole thing out. Might have to touch up the ballast after putting it back - not a big deal. I don’t expect to ever have to remove one, at least for a Tortoise problem - I have yet to ever see one fail, even in the club I used to belong to. Twin-coil machines like Atlas and Peco might not be quite that reliable - but you can go a long way towards extending their lives by using a capacitor discharge supply to operate them. With a CD supply, even a stuck control button won’t melt the coils.

I actually don’t think I will do any more this way. I discovered that the same culk I use for my raodbed and track holds the Tortoise very securely right on the bottom of the foam. The advantage of the top mount is that only the circuit board and a tiny bit of the Tortoise hang below the layout, making for more head room underneath, but in areas where I don;t have to crawl under, just stickign them to the bottom will work too. For the distance of 2" of foam plus roadbed, I will probably need to move up to a stiffer wire than that included with the Tortoise.

–Randy

I tired extending the Atlas pin by heating a length of .039 piano wire and pushing it into the plastic. It attached just fine but the entire flat part of the throw arm (on the controller) twists and the points of the turnout don’t move very well. You would have to reinforce most of the mechanism. Not worth the effort for a mediocre switch machine. Mine went to the parts box and undertable mounted tortoises went in.

Substitute the tortoise wire with your own (about 4-3/8"). Use the .039 or a bit heaver. Stock is .025, I believe. After installation cut off the excess at the top. It works every time on 1" foam under roadbed and over 1/2" plywood and you don’t see it.

For 2" foam just add an inch of length to the wire. Make sure that you have about a half inch diameter tunnel through the base so that the wire doesn’t get hung up on anything and you’ll have no problems. I mount the motors with adhesive caulk and screws. (The caulk holds it in place while I drive the screws. Double sided tape should work just as well.) Many people use only one or the other.

Karl

There are a few differences. First, the Pecos are smaller, and I usually punch the hole all the way through the layout so that I could, if necessary, remove it from underneath by disconnecting it from the turnout and pulling it down. (No, I’ve never actually tried that, but in theory it would work.) Next, I suspect that the Pecos are better made. They are all-metal construction, as opposed to the part-plastic Atlas machines. The Pecos mount vertically, rather than horizontally, so they only require a small hole (about1x2 inches) to access from below. Finally, the Peco design is simpler. It is a simple twin-coil which directly throws the pin to the points. The Atlas design uses a twin coil whose motion is perpendicular to the point motion, so there is extra linkage required inside the switch machine housing, giving a higher possibility of breakdown.

Most of my switch machines are Atlas surface-mounts, and very old ones at that. What I’ve been doing lately is making covers for them with plaster cloth, and putting scenery on top to hide them. For me, I think this will be an acceptable alternative, since these small knolls will fit in nicely with the rest of the hills on my layout. If I had it to do again, though, I’d probably go with either Peco or Tortoise. Nothing against Atlas, though, except the appearance of the surface-mount machines.

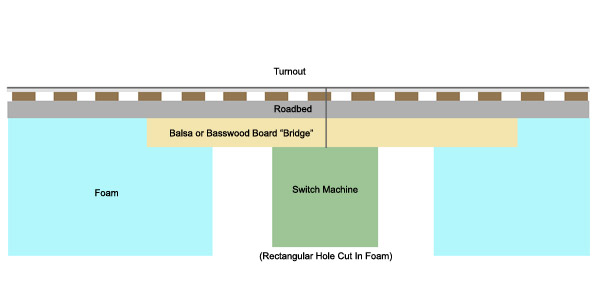

Here’s my solution:

- Get a small rectangular board of balsa/basswood/plywood roughly the length of your turnout.

- Draw the outline of the board in the foam.

- Within the outline of the board, cut out a hole big enough for your under-table switch machine to fit.

- Now cut out the foam from your board outline, as deep as the board is thick, so it rests snugly in a hole in the foam. Glue this wooden “bridge” to the foam.

- You can now drill a hole in the wooden board and

install the switch machine below it, through the hole in the foam.

Howzzat?!?!

Very creative! I like it! Abbie