I’m planning on building a freight yard. How many tracks would I want minimum? I’m planning on having about six industries. They’re all quite small and none of them can handle more than five or six cars per day.

My thoughts are that you need to provide some more information.

-

What is the purpose of the yard? Car storage? Make up/break up trains proceding towards staging? Make up/break up locals to switch industries? Serve as arrival point for cars destined for the industries with yard switching of the industries to follow?

-

Does the yard need to block the locals (sort according to how they will be switched)? Or just put them in a train for the local engineer/conductor/brakeman to figure out how to switch?

-

What is your normal longest train length?

-

Does the yard need to be efficient (accomplish its function in the shortest possible time) to meet the needs of the timetable? Or are operations sequential - the train isn’t scheduled to leave until the yard is finished making it up?

-

Do you have a track plan with number of car lengths of the various tracks indicated on it?

-

Are the industries part of the yard? Or are they located somewhere else?

-

What is the throughput of the yard as compared to the train consumption rate of the main? In other words, can you possibly make up trains fast enough to satisfy the needs of your main line? Or do you need staging to provide all/the rest of the needed trains?

A good guide for classification yard design is http://www.housatonicrr.com/yard_des.html. Armstrong’s Track Planning for Realistic Operation is another good source of information. If you read either of these resources, it becomes apparent that the number of destinations for your cars will impact the number of tracks (doesn’t have to be 1:1 or anything close). Your train

The purpose will mainly be to make up/break up locals. The normal train length is about five cars. The train wouldn’t be scheduled to leave until it was completed. The industries wouldn’t be with the yard. Each industry would receive two cuts of two or three cars per day.

If you look at the link I provided in the previous post (http://www.housatonicrr.com/yard_des.html), you can see that a passing siding (to serve as both runaround and arrival/departure track), a yard lead, and 2 yard tracks would be the minimum to have an effective yard. With 5 car trains, not much else is needed to make/break up trains - each train only has cars to/from 2 industries. If the yard is to serve other purposes (engine servicing, caboose holding and servicing, excess car storage, etc.) then additional track(s) may be required.

my thoughts, your choices

Fred W

Thanks for your advice. It was very helpful. I know have an idea of what I will need.

What Fred states (arrival/departure/runaround, yard lead, 2 yard tracks) is an absolute minimum to have a yard that is effective. Add a couple more tracks if you can, including another thru-track (runaround) if your yard is double ended. Yards and staging have a way of getting full fast!

Sounds like you are interested in an industrial spur off the main line and not a true classification yard. Industrial spurs tend to be built around the buildings and structures they are servicing. If the industries are close together they can share one- two a/d’s with the spur off the main used for the switching lead. With only five or six cars a day a single switch for each industry with two sidings would be more then enough. If a particular industrial yard is close to the A/d then only one siding would be necessary.

always make the yard twice as big as you think youll need

With a yard that small, I wouldn’t worry about A/D tracks, I would have one runaround and then just tracks. Prototype small yards don’t have A/D tracks, just tracks.

3xt, keep in mind also that your yard will take up tons of space. Length-wise on my layout it is ten feet from the end of the tail/drill track to the furthest points of the far turnout. This yard was designed to handle ten cat trains double headed with a caboose.

Plan, plan, plan, then plan some more. Think it through carefully before moving forward. Visualize your operations.

Spidge and others pushing the OP for a bigger yard.

The OP stated his train length was 5 cars, with cuts of 2-3 cars for each industry. Assuming 40ft cars in HO scale - dimensions would have to be adjusted slightly for longer or shorter cars and locomotives - the passing track that serves as combination arrival/departure and runaround needs to be about 50" long between the turnout clearance points. This gives 36" for 6 cars, 5" for a caboose, and 9" for the locomotive. The tails on the runaround needs to be at least 9"+18" (3 cars) or 27" beyond the turnout points for efficiency. Less will require additional switching moves at times to handle.

Checking the resources I have previously listed, if the drill track - yard lead - can handle a full yard track cut of cars plus switcher, efficiency is maximized. Half a yard track for the lead plus switcher is functional but will likely require additional switching moves. Since the OP is using sequential operations, unless there is a train circulating on the main while yard switching is going on, using the main as the yard lead can be used to save space. With the size of cuts and trains, I would try to size the minimum 2 yard tracks at 6 cars each.

I built in a one car cushion for every 5 cars in the calculations, which is probably about right to allow space between cars without coupling, and a little slop for spotting.

Building a yard bigger than the minimum I cited increases storage capacity, but does not add to yard efficiency for train makeup/breakup for the conditions presented. The OP is obviously talking about a smaller layout (like the ones I’ve buil

What you are talking about is what is called a outlaying yard that is used strictly for the local industries.There will be no engine service area,engine house or turntable.

You will need to allow for “overflow” cars.

You still wouldn’t need much of a yard 3-4 tracks top and the yard should be doubled ended.

As far as locomotive servicing…The engine can be refueled by contract fuel dealer.

Also known as an “industry support yard” or “satellite yard”. What the 10 commandments points to is a classification yard, which is different.

An industry support yard on a branch or industrial lead with only one or two jobs working won’t have a yard lead, A/D tracks, it will store cars in the yard, and the switcher will cherry pick cars out of the yard, breaking many of the rules which DO apply to classification yards.

I would have as many tracks as there was room for double ended, at least one, two is better and then then the rest can be stub. I would have the main, at least one open track (double ended), a track for inbound, a track for outbound and a storage track (the first to go if there isn’t room).

Dave,As far as “cherry picking” cars that is also done in classification yards.This how they make up urban and road locals.

" breaking many of the rules which DO apply to classification yards."

The only true “rule” there is in yard design is to design one that fits the allotted space.Anything beyond that may apply to Godzilla size layouts.

Mmm - a small industry support yard. Fred (and Dave) have given you good advice about a fairly small yard.

Here are four layout plans containing working yards of various sizes in H0 scale.

Here is a layout 6x10 H0 scale plan based on Linda Sand’s 5x9 plan from the article "“Big City Railroads don’t require big spaces” in Model Railroad Planning 1999:

As you can see - a four track yard with room for a runaround, engine service and a small enginehouse in 7 feet x 18". This might be bigger than what you need if you only run one train at a time, with maximum 5 cars in each train, and it might be bigger than what you have room for.

The yard in the Linda sand plan above also works as open staging & interchange - cars can be pre-staged here before you start a session and you could designate one track as an interchange track (where another RR has “just dropped off” some inbound cars or “will soon pick up” some outbound cars).

Here is another yard that probably is too big for your description - this one a H0 scale design based on David Popp’s N scale layout as it was a while back:

The plan above is intended to accept five 7-8 car inbound trains and redistribute cars between five outbound 7-8 car trains over a period of some hours, so it needs to be able to hold quite

I just finished my new staging yard. It was designed to simulate the operations of the 84 mile SP Branch line from Weed CA to Klamath Falls OR in 1910 that ran logging trains and small mixed trains at the time. It has a large wye at one end that doubles both as drill tracks AND inbound and outbound tracks from both Weed and Klamath Falls. At the other end of the yard, is a turntable. I am now testing this arrangement using timetables from that period and I am finding this design to be extremely flexible. Peter Smith, Memphis

MUST READ yard referance…

http://layoutvision.com/id19.html

Also the Kalmbach book on Freight Yrads and Andy’s artcile on yards

ratled

I see the reason I rarely come here to this forum are still shinning brightly.

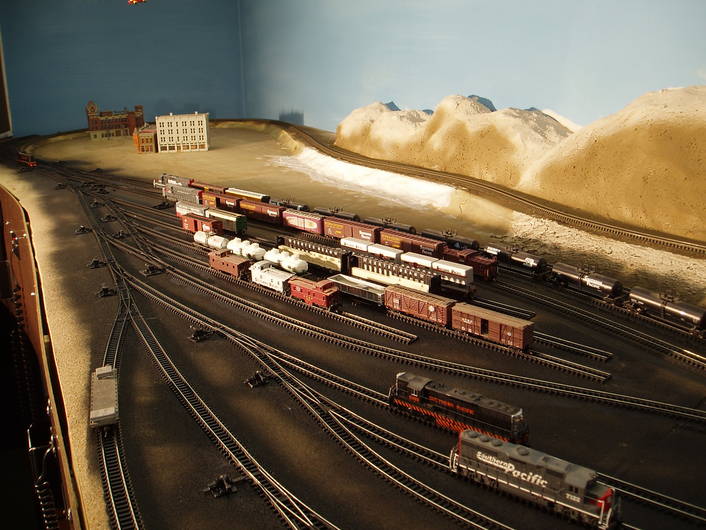

ttt I hope you were able to take something from us all and apply it to your plans. Show us a plan when you get it together, or a picture.

You took offense from Fred Wright pointing out that the Original Poster seemingly was looking for a small industry support yard where he would be handling 5-6 car cuts of cars for industrial switching, and that a yard designed to handle doubleheaded 10 car trains, with a dedicated A/D track, a decent yard lead and engine service facilities might be somewhat overkill for the this application ?

Let’s not get too thin skin here, people.

What kind of yard would fit the original poster depends a lot on how he plans to run his layout as a whole.

E.g. - if he plans to run several trains during an operating session:

Will more trains be coming from somewhere else (like a staging track, a staging cassette or some such thing) ?

Or will he fiddle the train by hand (ie lifting off cars and setting on new cars) when he is done processing one train of inbounds and outbounds ?

Or does he need to have room in his yard for a full day’s supply of cars - say 15-30 cars, depending on how many of his six industries with 5-6 cars each he plans to switch out in a typical operating session, with it being postulated that these inbound cars were dropped off by another train before the switcher crew came on duty, while the outbound cars left in the yard at the end of the day will be picked up by next night’s (not modeled) train passing through ?

Lots of ways to do things and have fun with a small yard. There is no one-size fits all and only one way to do it.

Even the advice of such excellent modelers as Craig Bisgeier (“Ten commandments of yard design”) and Byron Henderson (“A little love for the yard”) should be understood in the context they are writing about - how to make fairly busy classification yards more effective, so the yard won’t be a choke point on a layout being op

Stein said:For thinking about yard design, I would also recommend John Armstrong’s two booklets on prototype yard design and model railroad yard design from the 1950s. Still not outdated. Armstrong’s discussion of how to model yards is one of the best discussions I have ever read on how to do selective compression when planning yards.

Absolutely! I have little use for any layout planing book due to the author’s layout ideas but,I agree with many of Armstrong’s theories.

Stein said:How to squeeze in a yard for a single operator in a small space is a different angle than considering how to make yards more effective in a multi-operator environment.

Even the best yard design following Craigs “Commandments”,Byron’s article and Andy Sperandeo’s book “Freight Yards” there will be compression even on Godzilla size layouts–unless the yard is the focal point of operation where all trains enter from or departs to staging.

Designing a workable yard for a small layout requires what I call advance thinking beyond the normal box of small yard design set forth by layout designers over the years…