I know you can get a frog juicer for up to 6 frogs. My question is do you really need more than that even if you have many more frogs if you are just running one engine at a time or maybe two if they are in separate areas compleatly, like one working a yard ?

I suppose it depends on if anything else can be on any of the frogs on the whole layout. Frog juicers are automatic, so any piece of rolling stock with metal wheels could trigger it, thus flipping any other frogs connected to that juicer. It doesn’t have to be a locomotive.

How are you controlling the turnouts? Tortoises provide a SPDT contact set which may be used for frog power. Pecos have an add-on to the machine to do the same thing. I think Caboose makes manual throws with contact sets, too.

You could get away with this for some time, but eventually you may get a dead short you’ll have to deal with.

It might work if it was well thought out and you did the same thing every time. However if you got a wild hair and sent the local down to work the coal mine conflicted with what you were doing in the yard, you might have a problem.

“Frog juicers are automatic, so any piece of rolling stock with metal wheels could trigger it, thus flipping any other frogs connected to that juicer.”

I want to be sure I understand. If I use a Frog Juicer that controls 6 frogs, and an engine crosses one of the frogs causing it to flip, then the other 5 frogs will also flip. Is this right?

Thanks,

Jack

Presumably the frogs are all connected to separate outputs of the hex frog juicer and only one changes.

If you are using a hex frog to power 30 frogs, your guess is as good as mine.

Thanks, I understand.

Jack

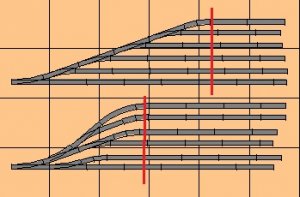

yes. that’s an interesting approach. may make sense on a yard ladder with a common mainline track

Each of the outputs should be independent and should not affect the others. The only issues from this thread come from using the six outputs of the juicer to control more than six turnouts by “double dipping” and connecting more than one frog to the same output.

A yard ladder is probably one situation where you definitely need independent control of all the frogs.

DCC allows you to run multiple trains and not be concerned with blocks for the track power and direction. For that reason, I don’t think you should deliberately create possible conflicts between trains, even if you typically run only one at a time.

The 6 outputs fromt he frog juicer are completely independent. If one trips, the other 5 do not.

If you use one putput to run 5 frogs each, then yes, all 5 will flip, because they are wired to the same output. If there is NO CHANCE of metal wheels rolling stock or another loco or lighted car passing over one of the other 4 frogs at the same time, you can get away with one frog juicer output controlling multiple frogs.

A yard lead would be a BAD place to use one output for multiple frogs - you have multiple frogs being traversed simultaneously while shoving cars in the yard.

I get people want to save money, but some of these shortcuts aren;t worth the hassle they can cause. If the expense of Frog Juicers is too great, use switch machine contacts or even a microswitch (which will work with hand thrown turnouts) to set the frog polarity. They are inexpensive, and once you realize which contacts close when the lever is released vs when the lever is pressed, it’s not hard to wire. The whole reason frog juicers were created was to set proper frog polarity in complex situations where it isn;t exactly obvious which frog should have shich polarity - specifically, Tim Warris’s CNJ Bronx Terminal layout where you actually have turnouts within turnouts and complex crossings. Yes, it makes it easy to wire, as all you need to do is hook the output wire to the frog and let it figure out which track bus wire should be connected to the frog, but of course there is a cost penalty associated with making it that easy. Like anything else, it’'s a tradeoff. Cheaper and a big more work, or more expensive and less work. For most common turnout situations, like a simple siding, there are far less expensive ways to power the frog than a Frog Juicer.

–Randy

yes, you’re right. i was thinking of the type of ladder at the bottom image below. the 3 rightmost turnouts would not be used togther, could in fact be controlled by a single frog juicer (of course you wouldn’t need frog juicers with tortoise motors

Wanted to use tortoise motors but they really don’t wook with 2" foam, let alone two with 6" foam.

All of my Tortoise machines are mounted with 2 inches of foam, except one that has about 4 inches. It just takes longer pieces of music wire. One of the adjustments on the Tortoise controls the range of motion of the wire.

Yeah, my understanding is on the Hex Frog Juicer, each out put goes to one frog, not multiple. If you did multiple frogs from one output, it could be trouble; further more, if you fry the Tam Valley frog juicer, you may void any warrenty by using them as not intended.

I have two Tam Valley Hex frog juicers so far and I plan on using them to power any metal frogs I have in staging and in the main yard. I’ll probably need around 7 of them in total, so I figure I’ll buy a couple at a time as I work on the layout.

They absolutely will work on 2" foam, both installed from the top and installed from the bottom. They would work with 2 layers of 2" foam, as I used on my last layout, but I had switched to using servos. But the servos move the points in the exact same way as the Tortoise, by swinging the piece of music wire from side to side. For thicker bases, you need to use a heavier wire than comes with the Tortoise is all. 6" of foam, I’d use the method I used 2 layouts ago, to installt he Tortoise from the top. First 3 photos under the 12/23/04 update on my page show how I did that: http://www.readingeastpenn.com/construction.htm That would work with any thickness of foam.

There was also an articvle in the August 2012 MR: https://mrr.trains.com/how-to/dcc-electrical/2012/06/easy-installation-of--tortoise-switch-machines-in-2-foam

(Yeah, mine was 8 years earlier - I should write articles on the things I come up with - but I didn’t come up with this either, I saw it a year earlier on the web site of some West Coast Free-Mo group. They used squares of thin plywood or MDF, I used the perfboard.) (I noticed a comment to the article by Chris Palormarez talking about the Free-mo group - that would be the one I got the idea from)

All track is in.

i understand many modelers are less technical. But knowledgable modelers use commercial products in safe and innovative ways.

The thing is, while technically sound IF ALL CONDITIONS ARE MET, there comes that one time when they aren’t. It can be something as simple as leaving a cut of cars over a turnout, not just someone running another loco at the same time. So while with planning, you can technically run multiple frogs off one Juicer output, the conditions have to be met 100% of the time or it will fail. The conditions being, only one of those frogs will EVER be traversed by a loco, lighted car, or metal wheelset rolling stock at a time. The minut something alters those conditions, it stops working. And such shortcuts usually come back to bite someone on the posterior some point down the road.

As for using Tortoises after the track is in place - there are alternative methods of linking a switch machine to the turnout that do not require drilling a big hole right under the throwbar, risking damage to already installed turnouts. Instead, they need a small hole for a brass tube drilled adjacent to the turnout, which you cna do from the top with no risk to the track. I had to do this for one turnout where there wasn;t enough room next to a crossmemebr even for a tiny servo, though I mut my swinging arm between the ties instead of alongside. A Tortoise, a servo, or even a solenoid machine can be used with linkage of this type - with a Tortoise, it can even be mounted on its side so it doesn’t stick down as far, and you get exactly the motion you need.

–Randy

it’s fair to say “I wouldn’t do it” and if so you shouldn’t do it.

but i think it makes sense. in the yard ladder situation i suggested, i think it is very unlikely that you would have a car parked with a wheel on a frog. similarly there’s no guarantee that there isn’t a wheel bridging the gaps at both ends of a reversing section.

but if this really does become a problem, you can simply buy another juicer and connect each frog independently. perhaps it makes more sense to share a juicer if you have 7 frogs and only one hex juicer.

i’ve been working on a 5 track staging yard with 2 reversing sections using dual frog juicers as auto reversers. we’ve had to deal with shorts in trackwork. the juicers handle them.

wouldn’t it be foolish to design a circuit that works by detecting a short but is damaged by a sustained short?

611 1226

Well, yes, but no matter how thoroughly a manufacturer tests something, in model railroading pretty much every installation will be somewhat unique. It might be the DCC system, or the type of track, or the speed of the switch machines, even the speed of the locomotive. You simply can’t protect against any eventuality because there are just too many of them.

We are already looking at unlikely events here. Chances are, many of them would never actually happen, but if you don’t design in possible conflicts, you won’t have them.

sometimes it’s harder to avoid all possible conflicts and easier to design protection circuits. that’s why we have circuit breakers in all sorts of devices.

643 1655