Early in the new year, I came up with some ideas for the blue box model, which has been annoying me for nearly 30 years. Take a look at the successful completion of the trial. The point is to upgrade to the same functional level as the Walthers Pullman-Standard cars.

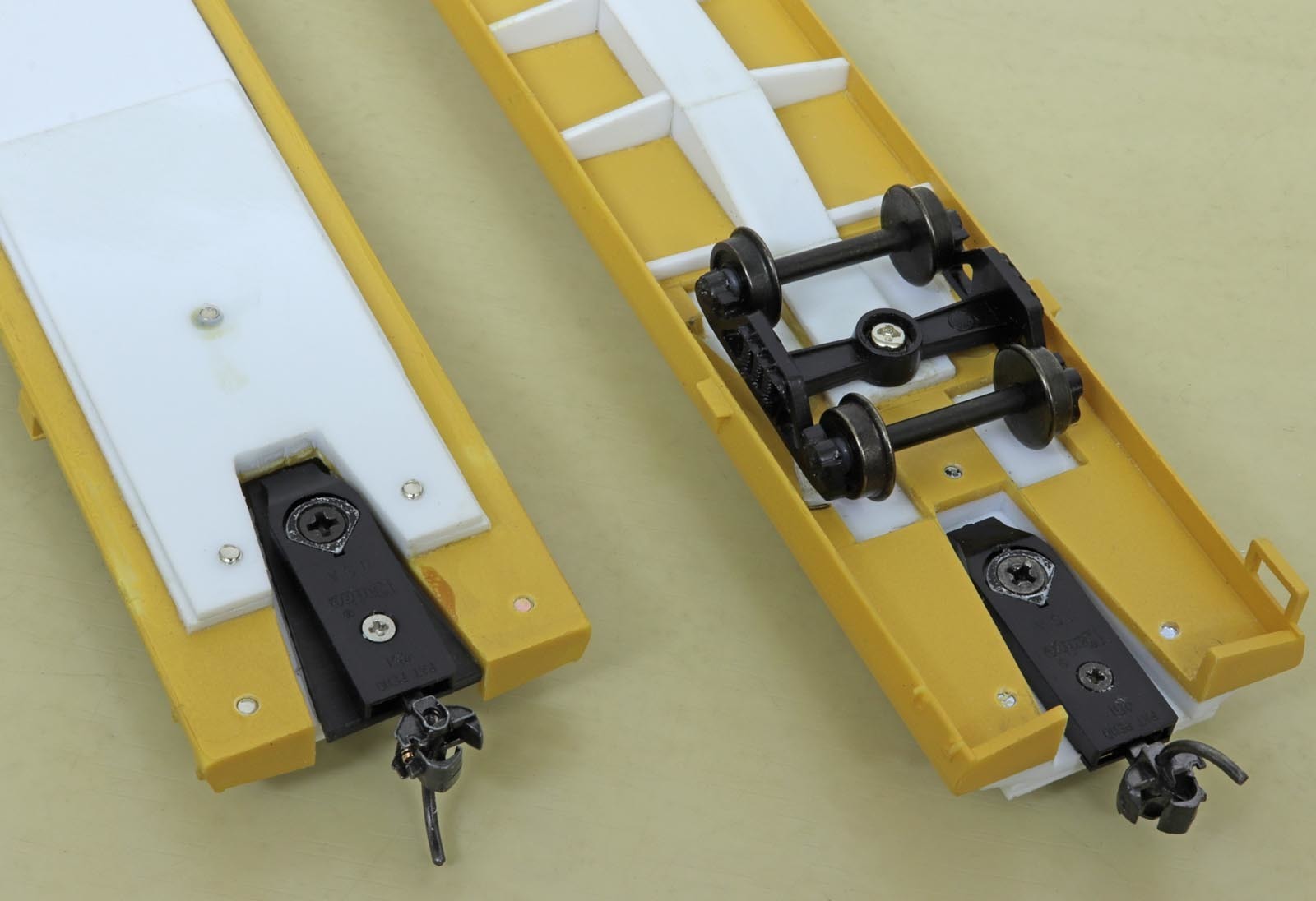

The left SP car is this modified one made by Athearn, and the right BN car is the target made by Walthers.

1. Swinging coupler pocket and cushion-underframe extention

Basically, add Kadee pocket #242 to Walthers conversion kit #933-997.

(1-1) Use 1.5mm thick polystyrene plate (PS, 6.4 x 18.5mm) for the joint. Since the swinging coupler pocket of the conversion kit is a polyacetal (POM) that is difficult to adhere, fasten it with two machine screws M2 x 2. The crux of the matter is to use the adapter upside down and to use the low head type for machine screws. The thickness of the pocket is 0.7mm, and the screw allowance is 1.3mm. Of course, the coupler rotation axis is shaved off. A sharp nipper and a flat chisel is useful for this.

Bonded the styrene-made pocket to the joint with MEK (methyl ethyl ketone). Cut 2mm off the tail end of the pocket to reduce the length. Since the lid is easy to come off, fix it with the low-head screw M2 x 4. Make a female screw hole in the joint plate, and the screw allowance is about 1.0 mm.

(1-2) Use the Kadee #118 Metal “SF” Shelf “Whisker” Coupler. Please note that there was once leaf spring type with the same product number. Although the shelf coupler is different from the prototypes, it is extremely effective in preventing the accidental uncoupling, which is likely to occur in rolling stocks with large overhang.

1.0mm thick shims (green) for the conversion kit are recommended. The calculation is 1.2mm thick. The body bolster shims (orange) are 1.2mm thick.

(1-3) Cut 1.2mm thick styrene plates to the appropriate size and shape, and attach them to the underside of the floor (19741). And attach the entire conversion kit with three screws. The thickness of shims clears the head of the low-head M2 x 2 screws and also serves to keep the coupler height. [P.S. Even if the plate thickness of 1.2mm is 1.0mm, there is no practical problem. The couplers originally tend to hang down, so it is better to attach them a little higher. The six self-tapping screws are four M2 × 5 and two M2 × 6, pan-head all.]

(1-4) On the other hand, Stuck a 1.2mm thick styrene plate (29 x 300mm) on the top entire surface of the plastic floorboard (this is of course done first of this kitbashing. 1.0mm thickness may be OK. In the case of exceeding 1.2mm, it is necessary to pay attention to the mounting position of the floor plate sinking stopper described later). Fix the steel weight (90717) with 2 screws from above.

This photo shows white 1.2mm plate affixed to the top of floor and steel weight (black painted) attached. The latter two (*1)s are the original machine screw positions, and the modification was intended as two (*2)s to stabilize the height of the couplers.

(1-5) Cut off the ends of the underframe (19742) so that it does not compete with the conversion kit (see the kit manual).

Left is assembled according to the Athearn instructions, and right is this modification.

(1-6) Cut off the part where the lower part of the car ends interference the coupler pocket interfere. Well, this cutout hides under the end platform.

(1-7) Key parts for the modification should be available in the United States. Living in Japan, I used “Yahata screws” for low-head screws and Tamiya 1.2 mm thick styrene plates.

Kadee #242 is included with #118. I got bulk pack #118-25 couplers and #242 pockets separately.

To be continued.

Kuriu, Kotaro

Kyoto JAPAN