What type of glue should be used to glue plastistruct brick sheet to a thicker styrene? It’s too large to use any of the “welding” solvents, & contact type cement, I am told will eventually eat thru the thin brick. water based adhesive is not recommended for plastic. has anyone had any experience with this? Thanks

Use a water-based contact cement.(the can will say soap and water cleanup)

I built a stone bridge, used a very thin cut stone pattern over thicker stuff, sounds like what your doing

I cut the tin stuff to fit,clamped it so not to move, and used reg, plastic solvent on all edges. The center maynot be glued, but so far you can’t tell by looking at it.

Don’t knnow how big your pieces are,may maynot work. Once the project is built, it just sits there,if you don’t 100% contact shouldn’t matter

Liquid Nails - be sure to get the plastic compatible version. Check the big box stores, they should have it is a toothpaste tube container size package

I’ve always used a slow setting CA glue. Just place a whole bunch of dots all over the surface and press them together. As a final effort, I’ll run some liquid cement around all the edges and door / window openings to ensure a good seal.

Mark.

I think it also depends on what type of material you’re gluing. There have been different types of “plastic” brick made over the years. Some of the older sheets made by Holgate & Reynolds and Champ Decals were more of a vinyl based material that didn’t seem to be affected much by solvent based glues. Other brands of brick sheets are polystyrene (or something close) and will be affected by solvents. I’m not sure what Plastruct sheet is made from.

I think I would try CA as Mark said. I’ve used it a lot over the years to attach brick with good results. I would even be tempted to try a thin coating of Tacky Glue or Weldbond instead since there is almost no chance they would react with most plastics.

Also, are you trying to precisely align both pieces? That could make using contact cement or typical CA pretty tricky. On the other hand, if you can attach the two and and then trim to size afterwards, precision isn’t an issue. Even if your piece of brick is trimmed to size and you’re attaching it to an oversize sheet of styrene, you can do final trimming later and not worry if the alignment is off a bit.

Jim

Hate to sound like a smart guy…but if You got the Plastruct patterned sheets, the grey/oxide color, that is ABS and the white sheets are styrene. It tells You what You can use and what they recommend to use. It also states that You can use solvent based contact cement, but too much in one area will melt the plastic…I use DAP original contact cement, spread thinly with a 1’’ paint brush, both pieces, let dry for 5 min. and put together…You must have Your pieces perfectly lined up though…cause You only get one shot at it…You Will NOT be able to take it apart.

I have been using their patterned and structural shapes for a very long time and have used nothing but their solvent cement Plastic weld, ZAP ca. and DAP contact cement…never had a problem.

If You bought Your pattern sheets from Plastruct read the sheet that came with it…all kinds of tips for using it, including painting…havn’t bought any Plastruct patterned sheet material that did not have that sheet in it. ‘‘How To Use and Finish Plastruct Patterned sheets’’.

Take Care! Good Luck on Your project! [:D]

Frank

Frank is right: Dap (or LePages) solvent-based contact cement will work perfectly well with styrene and Plastruct’s ABS sheet material. I use the gelled version (less stringiness) and apply it using a 2" brush.

Do follow the instructions regarding the minimum drying time before bringing the two surfaces together - not waiting a sufficient amount of time is the main reason that contact cement damages styrene plastic. I usually “prep” the styrene by using the same brush to first apply lacquer thinner over the entire surface (but only of the styrene), then apply the contact cement to the ABS, and then to the now-almost-dry surface of the styrene - this seems to give an even better bond, as the styrene otherwise seems to draw too much of the solvent out of the contact cement, resulting in a weak bond. I notice this more with the gelled version rather than ordinary contact cement.

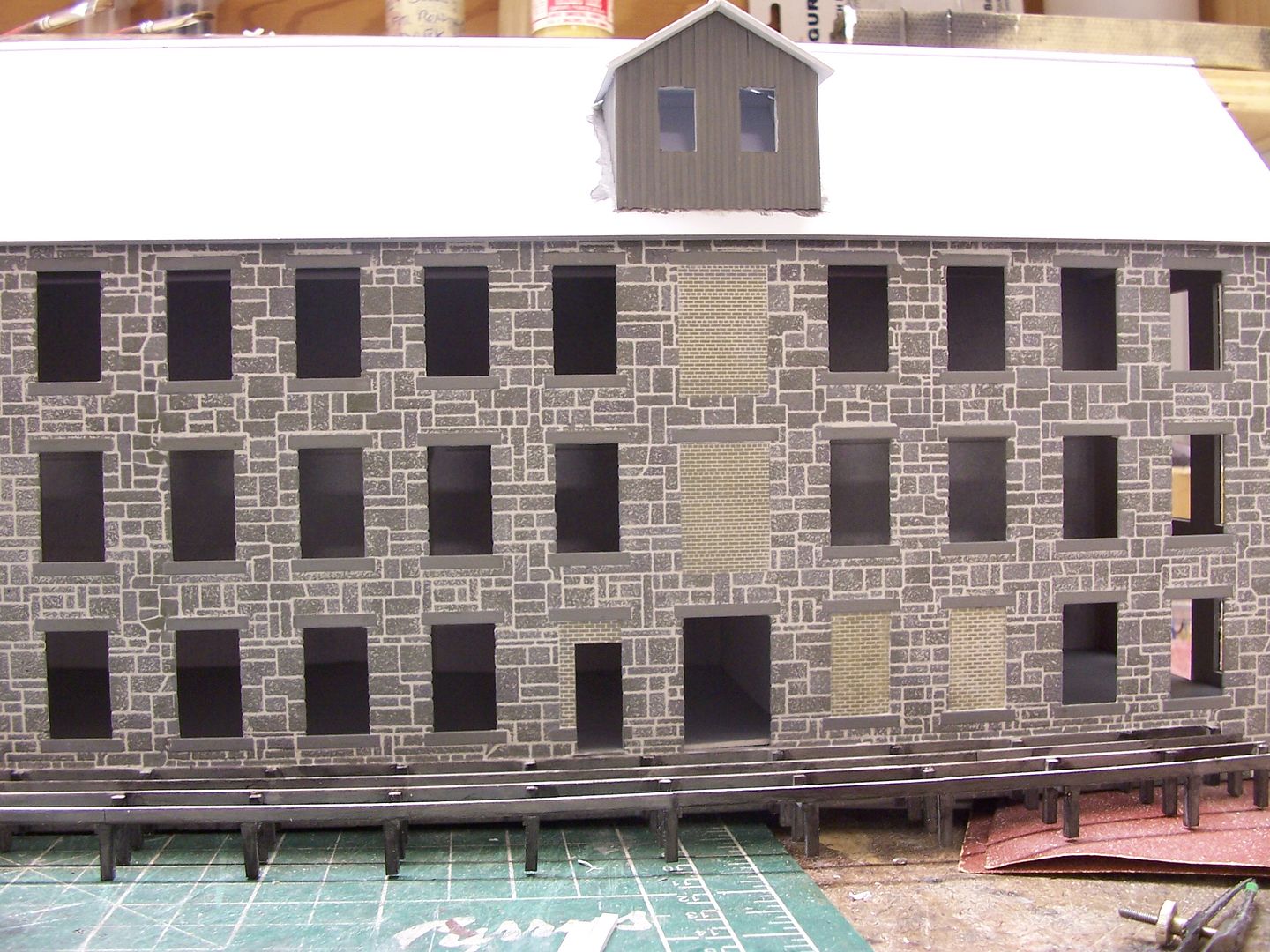

The sub-roof (and back wall and interior partitions) of this kitbashed structure was all done in .060" sheet styrene:

I used contact cement, as described, to add Plastruct shingle sheets to the front side of the roof and to the dormer roofs (the back side can’t be seen from normal viewing angles):

The shingles show-up a little better here:

If placement of the brick needs to be specific because of adjoining walls or raised details, wait until the specified drying time has elapsed, then cover the styrene wall with waxed paper. Next, place the brick sheet at a suitable edge or corner, and align it as needed, then pull the waxed paper to expose just that alignment point, and press the brick to the

The sheets I have are the plastistruck red sheets. The paper that came with them only mentioned the plastistruct adhesive & it would dry before I could position the back up sheet.