I want to model a rural grain elevator in 40s-50s time frame. If I want to be protypically accurate, how would the grain elevator be placed with respect to trackage? Would it have its own siding? Double-ended or single? I would think it would be off the mainline. Would cars (hoppers?) go under it one by one and get filled up?

Any tips appreciated!

In the '40s and '50s, a lot of grain was still moving in boxcars. The grain elevator would be on a siding, which could be single- or double-ended, and in many cases, there could be multiple elevators on the same siding. They might all be from the same company or could be from multiple different ones.

I read recently that grain elevators on the prairies were usually located at intervals of about 7 miles, as that was pretty-well the limit that a horse-drawn grain wagon could manage in a day.

Often, there would be more than one empty car spotted for the elevator, as the elevator operator could re-spot the cars as each was loaded. This was done either manually or with a winch and cable set-up.

I modified the Walthers elevator by adding a scratchbuilt farm-supply outlet to it, as it’s on the outskirts of town…

Wayne

The Canadian National Film Board has made available this fascinating look at the operation of a grain elevator.

You can see the operator [8:30] moving loaded cars away and bringing empties in place to load. Also shown is nailing the “grain door” into place over the car opening.

A very informative and enjoyable film.

Regards, Ed

The prairie grain elevator was the one must-have for me. In this blurry photo, you can see the grain emblems on the boxcars at the elevator.

There are You-Tube videos of them being unloaded on the coast. They basically pick them up and shake them around til empty.[(-D]

Stub end or pull through sidings were both used and different methods were used to move the cars as they were filled. A cable winch system was used as well as the method you see in the video Ed posted.

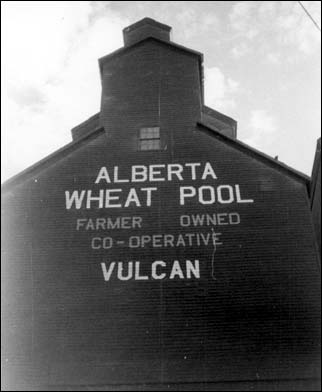

I have yet to post the name on my elevator but this is what it is to be.

Yes cars are generally loaded at a single loading spot/chute and moved past one by one.

So the elevator should be located with enough track on either side for the cars to be rolled past for loading them all.

And as noted, in the 1940s-50s hoppers weren’t really used for grain; plain boxcars were, with wooden “grain doors” coopered across the door opening and the car filled with loose bulk grain.

Hello,

I’m building the country grain elevator kit from laserkit.com

I have couple of questions regarding prototypical operation:

There is a short spout above the front door that looks like it is used to also dispense grain? What was this used for and why a second spout in addition to the main spout?

At the top of the elevator there is a door that opens with a pully system obiously used to raise and lower items. What was this used for?

Thanks in advance!

Can’t answer about the spouts without a picture.

The pulley is used to hoist equipment and parts up to the top of the elevator. Inside the elevator are several different bins to hold grain. There is a system of chutes at the top, above the bins used to direct the grain into the different bins. The block and tackle is used to hoist stuff up to the top of the elevator to repair or maintain that equipment.

Grain Elevator Placement???

That is a really good question Chris! Since I built one I’ve been wondering the same? I’ve always loved the Prairie Grain Elevators and always wanted to build one.

There’s only so much room on a 4x8 layout and I’m going to have to figure out how to squeeze it in some place.

I remember a grain elevator somewhere when I was young where my Dad took us to shoot clay pigeons down the railroad tracks. It leaned towards the tracks and had a Purina Logo on it. I wish I could remember where it is to see if it’s still there and get some pics. I still drive around sometimes looking for it to this day.

Nice looking grain elevators here guys! [Y]

TF

A grain elevator like the ones pictured would have a track by the spout. They are designed to load boxcars. The elevator would be in the “middle” of the track and it could load as many cars as there was room on both sides. So if there was three cars of room north of the elevator and three cars south of the elevator, then it could load 4 cars, one under the spout and three cars on one side.

The cars would be moved under the spout and filled, then the next car would be moved under the spout and loaded. They would use a tractor, horse, capstan or a pry bar to move the cars.

If the spout is out the side of the elevator such as the grey one pictured, the elevator can only load boxcars. If there is a spout that extends out of the elevator over the center of the track and higher than the top of a car, then the elevator would be able to load covered hoppers. The type of elevators shown pretty much died out about the time covered hoppers replaced boxcars, the wooden elevators didn’t hold enough grain. They were replaced with metal or concrete elevators with a much higher capacity.

The track was sometimes sloped a little to facilitate the movement of cars by hand.

Here is a picture.

Note smaller spout over front door?

I don’t think that’s a spout for handling grain. It looks like it could be a vent of some sort.

As far as placement, many have mentioned that the proper placement would allow an equal number of cars on either side of the elevator. To load 15 cars, you need room for 15 cars in front, and 15 cars beyond. So to do it “right”, they should be extremely long tracks.

I would simply shove the elevator all the way to the backdrop and just model the front half of the spur. Probably only enough to spot 5 or 6 cars if I had the room, and use imagination to say the siding extends into the abyss.

I have seen some layouts where the elevator is in the middle of a reversing loop with a short spur track. I don’t like that. Pick something else to put there. A farm supply store or feed mill that gets a small number of grain hoppers could work there, but I think of a grain elevator as being something larger.

If you use a double ended spur, it would have to be long enough to be convincing, IMO. I’ve seen many layouts where they run outside the mainline loop and parallel to the backdrop. The entire lenght of one side of the layout. Very impressive and dominant, and it reminds you that you have a grainger based layout.

Google search Tom Johnson INrail for some impressive pics and placment along the backdrop.

But, there is always placement in the middle of a curve, like when the crusty old farmer who owns the adjacent property makes you curve the track as to not touch a part of his pretty farm field.

My sister has this great big coffee table book of Prairie Sentinals and it has a lot of photos in it. The lower spout would have had a hose attached to it for when boxcars were used. The newer upper hose would have been added when hoppers came along.

Here is my little elevator siding.

Brent, that’s a great way to fit the elevator into a loop. The track is long enough to be convincing. I did a similar arrangment with an aggregate load track.

Thanks, Douglas, it worked out better than I thought it would. You can see a stub-end siding off to the right of that bench. That is where the Co-op will go. The bench is six feet wide.

I always liked that grain elevator of yours Brent. The weathering job and how the ballast Fades away as the grain grows thicker on the tracks from the overspill.

You posted it in one of my threads a year or two ago but where did the Red Deer go? He was red from eating all that amber colored grain[(-D]

[I]I think I must go look for him now.

TF

Every time Ed ask for something over a buck$$$$$

I need to adjust his colour at some point. That is slated for 2028.[(-D]

There he is!

I always got a kick out of that picture[swg]

TF

Nice looking grain elevator, TF

One of our layout partners has actually loaded boxcars at an elevator, or more exactly, driven loaded grain trucks to an elevator loading grain into boxcars. His Uncle was an elevator repairman…real elevator not office building.

When trying to figure out how an elevator works simply keep that name in mind. The bottom “half” of the elevator holds no grain, for obvious reasons.

In our fair City we have a “Heritage Park” with a working steam railroad and a working elevator with see through bits. Very interesting. Railway days are held every year and the local enthusiasts run the biggest toy train layout anywhere. The scale is 1:1 and the gauge is standard. They run to a schedule. They double head. They have Wye and a turntable both of which they demonstrate.

Also of interest, to me anyway, is that not all elevators were on the Prairie. They were also built wherever grain was grown, even “in the mountains” of BC. Before long distance trucking of grain to unit train elevator facilities became the norm.