Hi,

I have read many answer about this post and I agree whith the most.

However before killing Fastrack because of the price, Tim Warris has open the way about handlay turnouts and i’ts amazing to see how much great operating layout use their devices; a few weeks ago question on the MR forum was asking were to find custom made Fastrack turnouts.

Don’t forget a turnout in HO or Nscale turn around 20$; a medium sized layout need quickly 25 turnouts so a jig is an around three turnout…whith a full NMRA and fine scale turnout.

You can buy crossover jig so You have the cross and the turnout in one jig.

Tools except may be the frog tools are not really necessary; good file do the job.

And forget the laser ties; they are great but to much expensive; lay Your own.

Rails could be found at many store which make slow prices.

Not convinced, handlay Your turnout from scratch i’ts the cheapest approach but it take time.

You need also consider the scale You use; the smaller one like N are tiny to work whith.

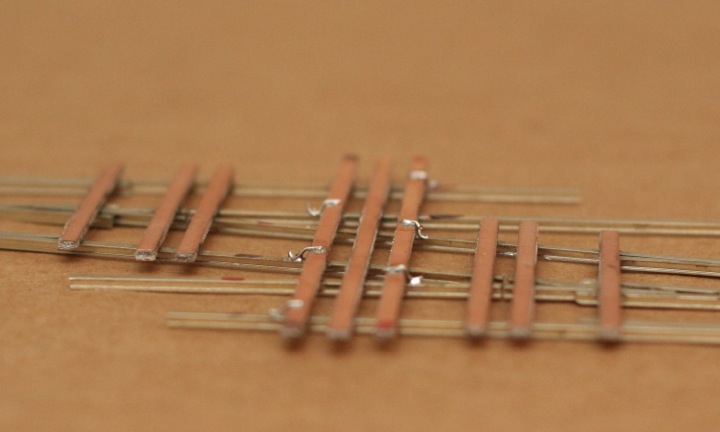

I am a user of the Fastrack Jig system but in Nscale; I use n°6, n°8 and curved n°8 whith additionnal custom jig for curved one.

Why, because in Nscale You need to be very accurate when building a turnout; I would say the Fastrack are somewhere to much accurate for steam loco and the wing rails at the frog need to be open like Mister Lance Midenheim explained in the january Mr issue.

You can produce a lot of turnouts , in fine scale and accurate, in a quick time, important if You are, like me, working on a large layout.

I build my turnout in serials, so I have some in stock; building them in batch allow me to know exactly whath to do for each one; building only one at a time and You forget some tips.

I also now handlay some directly in place were I need special turnout.

Yes expensive but take a look at this system it’s great anyway and helpful for the small scale to hanlay super turnout.

Marc