On the layout I am building I have easy access to all my track, 30" reach at most. Except in one spot I have a 6’ stretch of track that is perfectly straight with no turnouts but is definately out of reach. My question; should I just leave a hole in the benchwork so I can crawl under and pop up through or have a hatch that I can open to access this spot. Has anyone out there ever done the hatch thing and then disciused it to hide it? The area will be a prairie scene with grain elevators and a couple of horse head oil pumps. I thought maybe a farm or oil tank farm scene that I could just lift off when I needed access. Any suggestions would be appreciated.

Assuming a lift-out, three things to make it less obvious:

- Avoid a perfectly square or rectangular opening. If it’s asymmetrical or has a curved edge or two it won’t be quite as noticeable.

- Disguise the edges by putting them along fence lines, drainage ditches or the very edge of the ballast.

- Have one or two OPERATING horse-head pumps on the liftout itself.

The big PITA with a lift-out is where to put it when it’s not where it belongs. You might want to think about that.

Chuck (modeling Central Japan in September, 1964)

Yes. It is a common practice. I’ve seen people use mountains to hide them too. Someone just posted some pics of their lift outs and drop downs a couple weeks ago. Might want to try a search for those terms.

Sure, it’s a common technique. I have 7 different liftoff sections on my layout. In my case, they are small, and are intended to cover over the tracks in the tunnels underneath them, but allow occasional access if there is a problem.

I your case, I would build up a hatch cover out of 2-inch foam, and taper the edges so there’s a smooth transition between the cover and the rest of the layout. If you make the shape of the hatch irregular, it will be easier to hide the separation.

For mine, I first layed down a strip of plastic wrap (Saran Wrap, Glad Wrap, etc.) on the fixed layout side of the gap. Then I put the hatch in place, and put a 2-inch strip of plaster cloth across the gap. Once it was set, I removed the plastic wrap and applied scenic cover to the gap. Once that was all in place and dry, I carefully lifted up the removeable piece, taking the plaster cloth strip with it. This thin sheet covers the gap and conforms to any variations in terrain. I usually use a heavier ground foam cover right at the edge of the plaster cloth to further hid the separation.

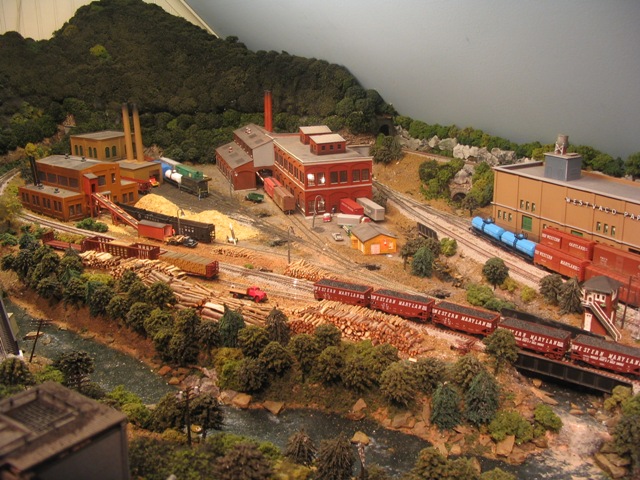

Here’s one edge of the layout with the liftoffs in place:

And here’s the same shot a minute or so later with the liftoffs removed:

These are, of course, much smaller than a man-sized hatch, but the principle is exactly the same. By the way, this shot shows 5 separate liftoffs.

In an issue of MRR I saw one where it was a building roof that came off and the modeler could come right out of the top of it. It has to be a large building though or a series of buildings interconnected, where all their roofs lift off all at once.

Or better yet avoid having an inaccessible part of your layout. there are many track plans that are great that can avoid that kind of out of reach scenerio.

Hello, fellow Lotus Lander. I cut out an opening around the littoral of my lake in my first layout. That way, the lift-out section, that sat on blocking screwed just below the lip of the orifice, was not so obvious. With a more-or-less wavy surface, the cut was hardly noticeable.

The advice given by others bove is quite reasonable in my estimation. Make it large enough to get one shoulder and an arm through, plus head of course, and that should suffice if you can perch comfortably and with enough balance to do what you must. Otherwise, make it large enough to stand. As Chuck pointed out, once you withdraw the lift-out/hatch, what do you do with it? Can you hang it on a handy hook set there for just that purpose, or will you merely lay it flat on the floor…and hope you never do actually kick it or step on it while thinking about, or reaching for, something else? In my case, I lifted it out (it was about two feet square and only 5/8" plywood with a thin veneer of epoxy “water”) and leaned it against the backdrop which was right there. That way, it was out of the way.

Everything on my layout can be reached from the aisle, although I have a tunnel that masks the return loops. To keep access there, I built a lift-off section of mountain…

N scale makes it easier since you can do a generous curve on a 36" wide deck.

Lee

Back when my father and I were building his 1st HO layout - our previous had all been Lionel on plywood boards on the floor - he built a 5ft x 13ft table with the long side against the wall. He quickly discovered the need for a couple of access points rather than climbing up on the table. He ended up cutting 18" x 24" access holes and hinged the plywood surface to drop down when needed.

Any scenery put on the hinge down surface was quickly destroyed by anybody standing up in the access hole with their legs bumping and rubbing the scenery. After redoing the scenery a couple of times - and us kids getting fresh scenery paint on our clothes - the hinges were removed and the hatches left permanently open.

If the layout is high enough, scenery or even a partial backdrop can hide the access hole. The scenery can be a simple as a small ridge that prevents direct sight of the front edge of the hole. Seeing the back edge through some trees or buildings is not nearly as disconcerting. The risk is that the scenery (or backdrop) to disguise the access hole hinders access to the areas that the hole was designed to allow you to reach. Reaching across scenery, track, and structures and knocking them with your arms, shitsleeves, or elbows is just as frustrating as knocking it with your leg on a hinge down section.

An access hole with a liftout section doesn’t work well because there is no place to set the liftout section. If there was, you wouldn’t need the access hole in the 1st place (there are exceptions).

There are no great solutions, just pick the drawbacks you can live with.

my thoughts, your choices

Fred W

I have a couple of them, for emergency, but I have another used to reach track and buildings in an industrial area. I used two Walthers kits, one of the large 5 story grey wharehouse type buildings, but I built only two walls. They frame two sides of the popup hole and are semi attached. I can come up inside the building if there is a need and take care of it. The two sides missing are not visible by any angle. The roof isn’t there as the area is about 5ft 4"inches above the basement floor. I have a little foot stool so I can become high enough to reach the tracks.

I even made it a working industry with a long spur next to it. The walls are super braced and a little corner of the roof is there to connect the sides and to provide a place for air conditioner and other roofy things.

Easy Deal!!

Bob