My DCC Sound President Washington B&O 5300 Broadway Limited keeps stalling and shorting out on an Atlas crossing at the apex of the crossover; I use the term apex to signify the place where the two track, four turnout (Which are atlas also) converge. Can the frog of the crossing by powered in DCC to allow a continuous flow of traffic across the crossover? Is it a bum or bad crossing perhaps? I will have to rebuild the crossover if that is the case. Will post a picture in a few hours.

As Atlas doesn’t make an HO double crossover is your crossover four turnouts with an Atlas crossing between the four turnouts?

As a new member you replies are monitored and take awhile to appear.

A picture would help especially if it is custom built.

Mel

My Model Railroad

http://melvineperry.blogspot.com/

Bakersfield, California

I’m beginning to realize that aging is not for wimps.

[#welcome] to the Forum Your first few posts are moderated and delayed. If you have no Russian brides to sell, it goes away.

Mel is our Atlas crossover guru. His page is here.

If we can believe his drawing, and I am sure we can, the frog rails are hot, powered by internal jumpers, I think. That little bitty frog isn’t going to stall out the President Washington

In a Peco turnout, the convergence of frog rails is a place where a short can occur. I don’t recall seeing the complaint about Atlas.

An internal fault could lead to a dead frog rail. A cheap Harbor Freight voltmeter could test that.

I’m wondering if there is something else in this particular loco that is causing a short.

And there’s Mel ! [:D]

I understand the OP to have constructed a crossover like yours. Don’t know what Atlas turnouts and crossing he used.

I used an Atlas crossing, not on a crossover, just between a couple of spurs. It was defective, behaving as has been described. I replaced it with a Walthers crossing and that worked perfectly. I just tossed it. For a few dollars, it wasn’t worth putting my LHS through the grief.

I gave up on double crossovers after spending several frustrating years trying to deal with three Walthers Shinohara Double Crossovers on my layout. Too many dead spots, too many derailments. One by one, I removed the failing DCO’s and replaced each of them with a pair of single crossovers. If you have the space, you should do that too.

Rich

Rich

That was my experience too. My problem was Rivarossi large flanges in the code 83 double crossovers, I should call them a derail crossover.

All of my Rivarossis articulateds cleared my Atlas code 83 turnouts, even #4s.

The fix was to make my own 2” center double crossover from #6 code 83 Atlas turnouts and 19° crossing, worked first shot and I haven’t had a derail since it was installed. The Atlas turnouts and crossings don’t require any special wiring to work DC or DCC from my shortest Varney 0-4-0 dockside to my Rivarossi 4-8-8-2s, RP25 flanges or Pizza Cutter flanges no problems.

Mel

My Model Railroad

http://melvineperry.blogspot.com/

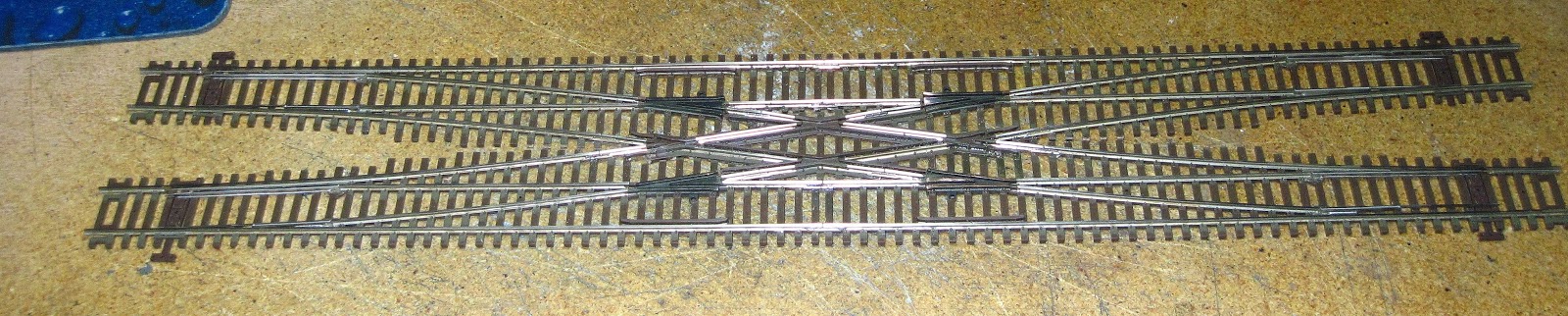

Here are a pair of double crossovers fabricates from Atlass (or other) turnouts and an Atlass Crossing. I think that the crossing works fairly well, your problem may be in ore or more of the turn outs. (click on photo for more detail)

LION does not bother to wire the crossings of him as 48 wheel power pick-up solves all problems. (solder all rail joiners, or power every segment of ail separately. — LION uses relays for power routing, and him controls each pair of turnouts with a separate lever. NOT all four straigt or reversed, but only one pair can be reversed. This is per ALL railroad operating proceedures. You can NEVER align a conflictiong rout.)

ROAR

You are correct Atlas does NOT make double crossovers, I constructed the crossover with a crossing of 12.5 degrees and four #8 turnouts. Having trouble attaching a photo, but maybe if you have the track and crossing you can construct one to look at. Sorry I took so long to respond, it is just too hot here in Maryland and I am feeling drained. Aging is not for the faint hearted to be sure. It is a pain if you ask me.

[Note: Language edited by moderator. Using Yiddish does not get you around our prohibition on adult language. Thanks.]

Anyone who doesn’t understand the track geometry can look at Lion’s or Mel’s (in my link above) crossover.

I’m not sure it would be helpful but you have to upload your picture to a photo hosting site like Imgur.com and then provide a link. Directions are here

Do you have other engines that can negotiate the crossover without stalling/shorting?

There are 4 ways it can enter the crossing. Does it short out in all those directions?

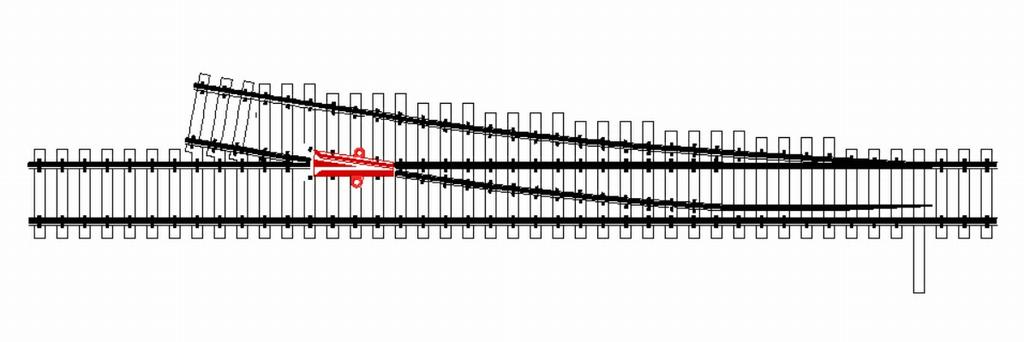

Shamelessly stealing Mels’ photo, this shows the polarity of the crossing

Your degrees are different but the polarity should be the same. Green on the crossing ought to be in continuity with green on the mainlines and red with red. Red and green should never be in continuity. If there is a dead section of track, it would be easier to install a feeder than ripout the crossing and a couple turnouts for replacement. It could even be a poor connection at a rail joiner.

Unless you live on the Eastern Shore, there ought to be a Harbor Freight, within an hour from you.

Mazel tov for being censored for Yiddish. [:D][}:)]

Edit are there any insulated rail joiners in this story?

Unless you are older than me your still young no matter how much pain you are experiencing, I turn 82 next week.

Henry ask a good question, any insulated rail joiners?

Here is a picture of my double crossover, click twice for max size.

There are no insulated joiners in mine and everything works perfectly.

EDIT:

I used Shinohara low profile joiners, only the two outside joiners are soldered, there are no insulated joiners in my crossover. The only reason I soldered those was to prevent the assembly from coming apart during installation. The 19° Atlas 572 crossover has internal jumpers.

The black rails in the picture Henry posted are plastic and prevent any shorting.

Okay, I sped my non dcc engine to 80 and ran across the double crossover, no problems, my DCC engines all stall out and try to reboot or just lie there dead, slow and fast. dcc engine also wants to derail on the crossover where the non decoded engine cruises effortlessly over the crossover even slower around 45 this leads me to beleive that i have a dcc issue and not a conductivity one, should I dedicate a booster (I ran Digitrax exclusively) to the crossover and other dcc dead places? I have a small 6 by 14 layout, I shouldn’t need a Booster like that what is a resolution?

Just to be clear on what you mean by reboot, does the engine stop, sound stop and then restart or does your system reboot? You did mention shorting in your first post.

I believe some of electricty is magic, but DCC causing an engine to derail is a stretch, even for me. That will bring things to a stop. Are the wheels and track in gauge?

If it’s a DCC issue, I don’t believe a booster would help. DCC is more demanding than DC in terms of the quality of the signal. It could be a bad rail joiner connection, because of ballasting track weathering or just corrosion. We haven’t entirely ruled out a bad crossing.

If there’s a question of not enough voltage or no voltage, you should measure it, rather than throw $100 or more at a booster, spend $5 on a voltmeter and find out for sure.

Do you need a dedicated booster for the double crossover? No way!

A single booster is more than enough for a 6’ x 14’ layout.

Conductivity can be tested with power off, using an ohmmeter.

Are you experiencing stalls or shorts with your DCC locomotives?

Do all DCC locomotives derail on the double crossover or just one locomotive?

Rich

If your DC locomotives clear the crossing the DCC locomotives should also. It doesn’t matter whether the power source is DC, DCC or batteries won’t have any effect on derailing. That is either a wheel, truck or track problem. As your DC locomotives don’t derail the problem is in your DCC locomotives. Are the DC and DCC locomotives the same type, 6 axle diesels, 4 axle diesels, steam??? How about manufactures or age of the non working locomotives.

I had several LifeLike/Walther? Proto PA1s that didn’t like the S turn, there was a problem with the PA trucks. My Proto E series locomotives worked ok but the PAs constantly derailed. The PA wheels were in gauge but wouldn’t clear my double crossover. New trucks fixed the problem.

EDIT:

Walthers replaced the PA trucks (6) under warranty.

Mel

It is that the DCC engines are indeed stalling over the insulated frog of the crossing and the adjacent turnouts. I can wire the Atlas frogs on turnouts, but do crossings have the same feature? Can’t find one on any of my atlas crossings. Any suggestions on the proper way to juice a frog on an Atlas crossing?

Thank you Mel and everyone – but does anyone know how to wire a frog on an atlas crossing?

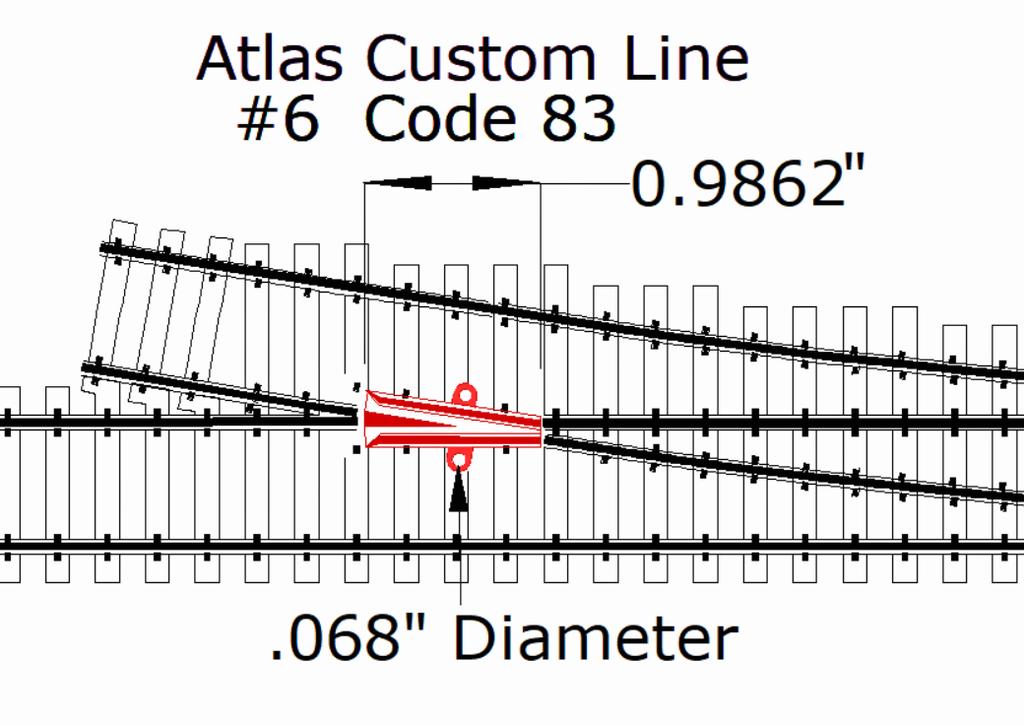

Here are a couple of my drawings of a Atlas turnout. The hole will except a 2mm tap for a 2mm screw from below, cut off the excess at the frog after the screw is tight.

I don’t have any #8 Atlas turnouts but I’ve never had an electrical problem on my #6 turnouts even running 4-4-0s. Have you confirmed that your locomotives have all the power pickup wheels working correctly, it is very unusual for even short locomotives to have power pickup problems on Atlas turnouts.

Don’t attempt to solder to the frog, the heat will destroy the plastic ties.

Mel

<

As I’ve never had any reason to look closely at a #8 I did so this morning and the frog is totally different from the #6s, no holes. As it’s really different I decided to take on drawing one up on my CAD. It will take some time working off an Atlas picture but when I finish the drawing I will post it here complete with dimensions.

Sorry for miss leading you! Without having a turnout to work with I can’t tell you how to connect a wire to the frog. The frog appears to be about 2.3” long and that could be a problem with power pickup.

There appears to be a terminal at the end of one of the ties in the Atlas picture.

Mel

My Model Railroad

http://melvineperry.blogspot.com/

That’s what I am seeing on the MTS website too. And the frog on a #8 is really long compared to smaller turnouts. Maybe powering that will be enough. A 1-78 brass screw will work also, a 2-56 is too big. 2mm is in between the two.

If the crossing frogs are metal, Atlas metal frogs don’t accept solder. You will need to drill and tap a hole for a 1-78 brass screw. Cosmetically it would look better if done from underneath, but there must be some jumpers somewhere to power the frog rails.

As a newbie, to us, we don’t know what you don’t know. The frog needs switchable power so it can change polarity.