I am guessing a lot of us would find that interesting and enjoyable…I would tune in regularly for something like that, myself!

Anyone know where I can get some the MS Train Sim data for PTRA?[:D]

I am guessing a lot of us would find that interesting and enjoyable…I would tune in regularly for something like that, myself!

Anyone know where I can get some the MS Train Sim data for PTRA?[:D]

I doubt we are that “famous”![:D]

We work on what is know as the ZTS system…Zone, Track, Spot…

We have a book of “maps” of the PTRA with each zone marked, then each track with its number, then each specific spot for cars, if that industry requires that service.

Switch list shows if a car is a zone car, to be forwarded for further handling before spotting, or a spot car, already assigned a specific place inside a plant.

So, with out a ZTS diagram, it will take me a while to figure out how to work this, but I will try.

Ed

From what I know of you on this forum you probably are more ‘famous’ than you might want to acknowledge. I look forward to your further ZTS information. You’ve already provided me some valuable insight through your switchlist description. Sounds as if cars in a PTRA train are grouped,or have to be flatswitched and grouped, to be ready for a specific pull or set of pulls which are governed by the ZTS protocol. Individual yards could be intake, staging, and pickup, I would imagine, for industry delivery and pickup. I for one appreciate the significant amount of research this will most likely entail on your part. I look forward to further posts as you are able to make them.

Best Regards

Charlie

Chilliwack BC

Rely interesting reading, ED. As others have said you rely can explain the work you do. Reading your answers through out the forum has taken my knowledge of refineries, SIT yards and the different aspects of car fording to a new level. It’s a truly fascinating type of railroading.

I do have a couple of follow up questions.

First about Phillips, do they (and the other big refineries) lease cars from one sole company or do they have cars from different companies. Also what inbound loads do they get (most of the feedstock would probably come by pipeline?), and on average how many inbound loads would it be in a 100 car train.

The thing you wrote about modeling in HO. It would be interesting if you’d like to elaborate about it a little more.

I’ve located most of the yards with the help of old Trains articles about, but were is your marshalling yard situated? Also does the intermodal yard east of Deer park belong to PTRA, and who brings trains in to that yard?

/Mattias

Mattias…

The intermodal yard is Barbours Cut.

It belongs to the Port Authority of Houston, and is served by the PTRA, UP and BNSF.

Because BNSF has no connection to Barbours Cut, they deliver the trains to us at our Pasadena Yard, and we take them out to Barbours Cut.

UP also serves them directly.

In the works is BayPort Terminal, an even bigger intermodal/multi use facility, which will be served by the PTRA and UP.

It will be located just outside La Port Texas also.

This is Barbours Cut, if you scroll down the shore line, you will find the BayPort site under construction.

The Marshaling Yard is a jointly owned yard, belonging to several different refineries, Dow, Auto-Fina and Solvay, and has a small switch engine of its own, but we have exclusive rights to serve it, and are the only interchange railroad.

Because their switcher can not come out on our main line without our yardmasters permission, and because there is no other connection to any other railroad, we alone serve it, although Solvay, which has a pretty big private yard of it’s own, can and do use it to store their cars, and has a contract switching service which pulls and spot their cars there.

They also have track right between their yard and the Marshaling yard, but require our permission to exercise those rights.

To make things a little clearer, we operate in “Dark Territory”, under RTC,

While I can’t add much more “on the ground” information to Ed’s always excellent postings. I can add a different perspective. Depending on which hat I’m wearing on a particular day, I could be responsible for managing just one yard or three yards, plus 25 or so miles of mainline in between.

We use a similar ZTS system. But rather then switch lists, we use work orders that list cars to be pulled, cars to be placed, any interplant moves, and any other special instructions. These can either be paper, or increasingly electronic via our Onboard Work Order Device.

Most of my customers have a pool of cars in one of the yards to draw on. Some order in specific cars. These ones are easy, you just dig out the ordered car and spot it.

Others simply request any available car from their pool. These are a little more difficult, because you have to decide which car to dig out and spot. The crew wants use the easiest car to get at. The better choice, operationally, is the car with the highest car hire costs.

Throw in switching windows, mainline traffic, multiple railroads serving the same customers (we have a couple like this), the inability to get the proper cars, and any number of other issues. Managing the operation is like orchestrating a military action. Unfortunately, I find the “enemy” is often other departments within my own company.

I got in trouble one day for appropriating cars not assigned to a customer, for him, because I didn’t have any cars assigned to him to spot. I’d been doing this for a week, because car management refused to send me any of the proper cars. The customer was happy, but car management had their undies in a twist.

Nick

As a modeler who also railfans, I find Ed’s posts EXTREMELY informative. I grew up in New York City when the West Side line was still running tri-power locomotives and Brooklyn was a webwork of rails, so I’m comfortable with the physical aspects of moving shipments from origin to destination (whether next door or 3000 miles away.) Ed gave me a better understanding of the financial aspects.

Speaking now as a modeler, it is infinitely easier to build a single track through scenery than it is to build even a highly compressed metropolitan industrial district of the same area. Also, my interest is more in the civil engineering aspects of putting rails through difficult terrain. I pay lip service to the realities Ed describes so well by having my railroad move trains from a major port (two hidden staging yards) to an inland industrial center/transportation hub (two more hidden yards on the other end of the railroad,) but choose to model the rugged, minimally-populated country between. Part of the reason is that I don’t have the staffing required to operate a major terminal (there’s only one of me.) The other part is that I’m trying to represent an area (and a lifestyle) familiar to my wife and very enjoyable for me - a specific forested mountain valley, not an industrial area.

However, I actually model the concept that is the subject of this thread. My mainline railroad interchanges loose cars and solid cuts with a coal-hauling shortline owned by the same company that owns the collieries. The interchange procedures are dead simple. Loads get pushed into one end of a track by the shortline, and pulled from the other end by the JNR. The parallel track works empties in the opposite direction. Of course, the car count is measured in a dozen or so per ‘day,’ not hundreds - but the normal (prototypical) freight train only runs 20 cars or so.

Sometimes I regret not being able to mod

I’ve been spending quite some time following tracks in and out of industries around Houston using Google. As said before it’s not always easy to see were one plant begins and another ends, nor which yards belongs to RR and which are part of the plants. So, thanks for the links Ed they rely clarifies things.

Looking forward to those ZTS maps. Hope you’re able to post them.

Nick

Where you have multiple railroads serving the same customers, do you all use the same tracks? If you use the same mainline, do you have different tracks inside the plants to deliver to and pick up from?

Also, how are the work orders different from switch lists?

/Mattias

I enjoyed reading all the post about house switchers. Very informative. Cleared up some things for me too.

Bob

Ford’s Chicago Assembly Plant was switched by NKP/N&W under contract and received cars from both N&W and BRC. In the 1960’s-1970’s, the plant was sandwiched between the N&W main on the west and Torrence Avenue/CWI main on the east. The plant lead extended southeast past 130th Street between both main lines and connected with each. BRC only delivered loads to the plant while N&W jobs which switched the plant would deliver loads and remove empties while en route to and from Calumet Yard.

Work orders list the cars to be pulled, spotted, any interplant moves and any other special instructions.

They also have places next to each car to list:

When filled out the work order is given to a clerk to enter all the information in the computer and complete the work. Increasingly, we use electronic devices (like the UPS man has) to record and transmit the work order information directly to the customer service computer, eliminating the need for a clerk to enter the data.

In my territory, the multiple railroads use the same track to access the customers. Most are located on a paper railroad company, the PBL, owned by the city. This allows each company unrestricted access to the customers. Each company has a seperate yard connected to the PBL. The city granted one company the authority to govern movement on the PBL, so all the other railroads, must contact that railroad for permission to occupy the PBL.

Some customers have specific spots for each company. Others are less formal, and simply ha

Ok,

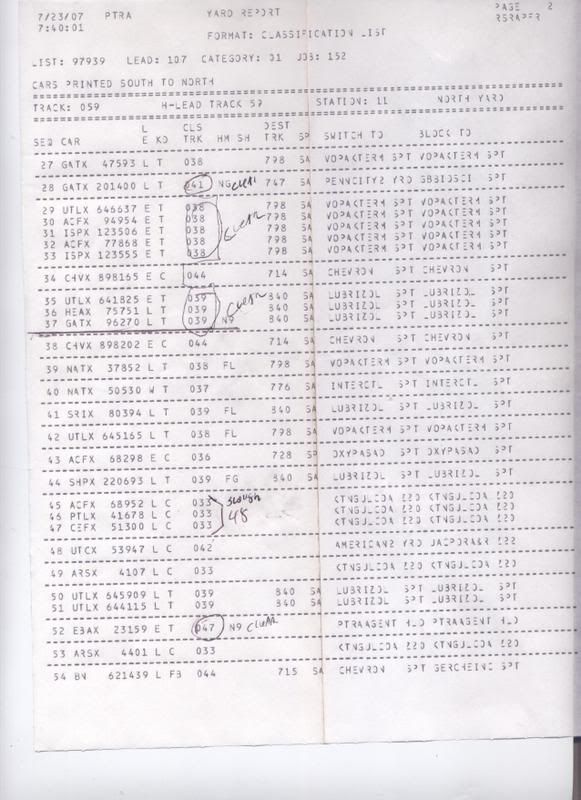

Not ZTS maps, but “switch lists” or classification list…this is the paper work I use to classify cars when I switch them out.

It tells you the date, time and what job this list is for, and where it is switched at…in this instance, it is list 97939, to be switched off the 107 lead by job 152, or me!

Note it states “Cars printed south to north.”

For those of you not familiar with the concept, it is simple a way of telling railroad crews which way to go.

It is not a reference to geographical directions.

All railroads run either north and south, or east and west.

So, on the PTRA, if you are traveling away from North Yard, you are headed south…anything headed towards NY is headed north…North Yard is also the Northern terminus of our railroad.

So on this list, car #60 is the most northern car on the list, and my locomotive will come against car #1, because I work on the south end of North Yard…confusing, huh!

If I worked on the North end of North Yard, I would come against car #60, and the last car on my list would be #1.

To help you understand what this list tells me, we will start at line 1, car ECUX 575121.

Self explainatory so far, but see the notations across the top…

Seq car L/E KD CLSTRK HM SH DestTRK SP Switch to block to

Seq car…what sequence in the list.

L?E loaded or empty

KD, kind of car, (hopper, box, tank)

CLSTRC…what track in North Yard it will be switched into.

HM…hazardous material and type…FG mean flammable gas, DW is dangerous when wet, PO is a poison, FL is flammable liquid.

SH…shift able or

Excellent as always Ed.

It’s been quite sometime since I had to switch a swithlist, but I can still easily read your’s. Give me a minute to learn the layout of your yard, and I could go out and drill that track.

Your switch lists are far more detailed then ours. My computer generated switch list (like yours) include only the car number, load status, car type, class code, target track, and any special handling codes.

When I’m wearing my yardmaster hat, I use a different method. I pull a track list, that includes: car number; load status; car type, length and weight; class code; contents; special handling codes; and the consignee and off station milepost. I then mark that list by hand with the target tracks, and make notations for any special moves that need to be made, such as: spacing dangerous cars; proper placement of High Wides, blocks of loads, or blocks of empties. Granted this method works best in smaller facilities, but I prefer the flexiblity it gives me.

You are correct about the addition train information attached to the work order. I tend to regard the work order and train consist as two seperate documents, because I can generate train consists without generating a work order. So, I didn’t think to mention it.

Nick

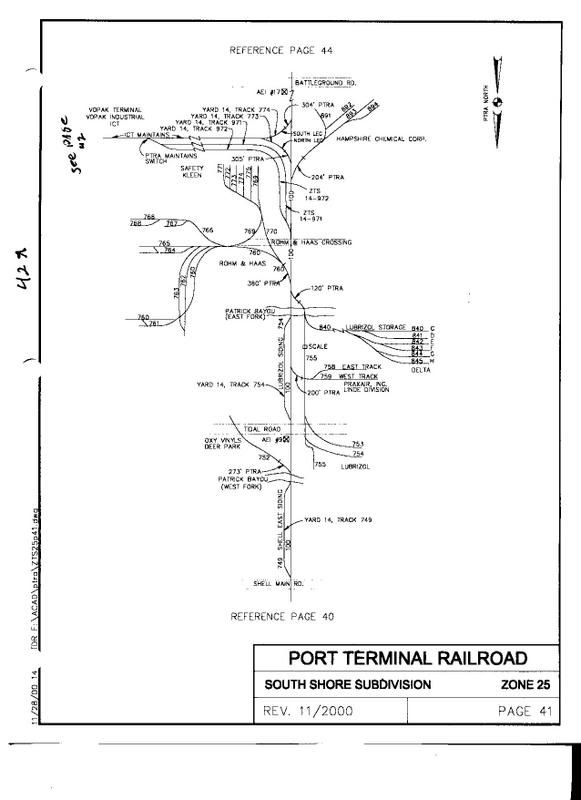

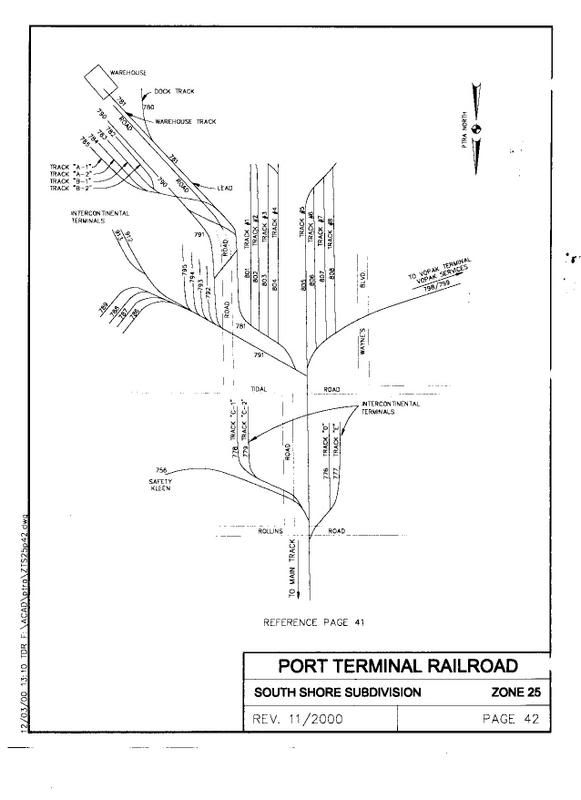

Ok, time to get the scotch tape out.

Lay page 41 on your desk, with the PTRA North arrow pointing to the left, place page 44 next to it, on the right side, also with the arrow pointing left.

Back to page 41, note on the top my hand written 42 with an arrow; page 42 goes here, with the PTRA arrow pointing down.

With page 44, you will find a notation that state "Reference page 45…page 45 goes here, also with the arrow pointing down.

So, from left to right, you should have page 41, with page 42 at the top, page 44, with page 45 at the top.

The bottom two will be laying on their sides, the top two will be upright.

Some things to note and study.

You will see notations that state “306’ PTRA” or “120’ PTRA” with a small arrow pointing at the track…this means the PTRA maintenance ends here, the industry is responsible for the remainder of the track, or that PTRA ownership ends here.

Other things to note…track 755 in Lubrizol has a derail owned by Lubrizol, located where our maintenance ends, almost on top on Patrick’s bayou bridge.

There is a company owned and controlled gate at the beginning of track 840 lead, just past the switch, it is usually open.

Lubrizol has their own in house switcher, and they leave their pull cars here on track 840, just past the gates…the cars are coupled up, but the air hoses are not laced.

Hampshire Chemicals has a derail and gate where our maintenance ends, they control both, and you have to call ahead to get the gate opened and derail down.

Hampshire is a guarded facility, they use and ship Hydro cyaniatic acid, cyanide liquid whe

Hi Ed

Got your info. Thank you. Got the PTRA laid out and blown up to a size I can actually read the track #s and other descriptors. Have been reading and annotating your notes as posted. Awaiting the ‘work order’

Now the fun begins!

Charlie

Chilliwack, BC

Okay…

I condensed some of this.

The Trainsheet will also count as your wheel report and Hazmat info…if I did a real one, Bergie would have gone nuts, those things are about the size of a phone book!

You will be working under RTC, radio traffic control, and under the direct orders of the Pasadena yardmaster.

Max speed is restricted speed per GCOR, not to exceed 20 mph.

All moves inside any industry must be made with air on the rain, outside the industry it is up to you.

For the purpose of this exercise, consider the train to be in track 101, Pasadena yard.

(far left off your map, not shown)

The cars are listed south to north.

The train has been on ground air since last night.

Your locomotives are in track 102, North end of Pasadena yard, you go on duty there and pick up all your work orders and trainsheet from the yardmaster on duty.

Your locomotives are coupled at the long hoods, with the fronts facing away from each other.

MK1500Ds, designed just for this type of work.

Your crew consist of an engineer, you as the engine foreman or conductor, and a switchman (brakeman).

The yard master informs you that you will have to take 25 covered empty hoppers with you on the rear of your train, for job 233.

Job 233 works back in towards Pasadena yard, he goes on duty 1 hour before you, and has all his pulls already done, and in Shell siding, but he only had one locomotive, so he left his spot cars in Pasadena track 3.

They were on ground air also.

You will take them to him, and figure out how to get him on his cars headed north back towards Pasadena.

You have to do

Ed

Thanks for the exercise. The orders came out fine. Give me about a week. I’m on a steep learning curve for PTRA operations.

Charlie

Chilliwack, BC

Work orders and switch lists, now I see the deferens. I appreciate how detailed your explanations are Nick and Ed.

Thanks Ed for the ZTS maps. They’re very interesting to look at. I can see now that when I earlier tried to use addresses picked up at the refineries homepage to figure out to which company the different plants that I were looking at (using Google maps) belongs to, I only got it somewhat right.

I’m looking forward to dig in to the task you’ve cut out for us Ed, it’ll be fun.

/Mattias