The real problem is derailments.

Yards have them all the time.

Even though they are slow speed derailments, they still drop tons of weight on the tie…and depend on what type of derailment, say I kick a few cars and they get on the ground, they can roll a few car lengths…wood ties can flex and absorb that, steel ones don’t.

Either a carman misses a sharp flange and we pick a switch, or a knuckle gives in the curve, maybe a dumb switchman lines a switch under a car, lots of things can cause yard derailments…but the point is a wood tie will withstand a tremendous amount of punishment, plus you can flip it over and reused it.

Concrete ties can take a pretty good pounding, but if they break all the way through, they have to be replaced depending on how many broke and how close together they are.

Steel ties bend, and pull the track out of gauge.

If you break a steel tie, and weld it back together, it will break again, right next to the weld.

Steel is cheaper, and easier to install rail on, but require a specialized tamper to work the rock up under the ties, which are hollow plus the ballast required is larger than what you want on a walkway/toepath, which we have to have.

In the photo showing the yard proper, I walk between all of those tracks all day long, and up and down the lead, if you look close, you can see the “paths” we end up walking in the rock…I might get in 4 miles a day.

So we have to have a layer of small ballast to keep the knee/foot injuries down.

You cant tell in the photo, but the yard curves away in the background, towards the right about another ¼ mile.

This place is pretty big, the empty track in the photo is track 33, there are 32 more tracks to the left, plus two run through tracks.

The rock that works best with steel ties is too big, and with the size of this yard, it is cost prohibitive to put down the right rock for steel ties, then a layer of walkway rock on top

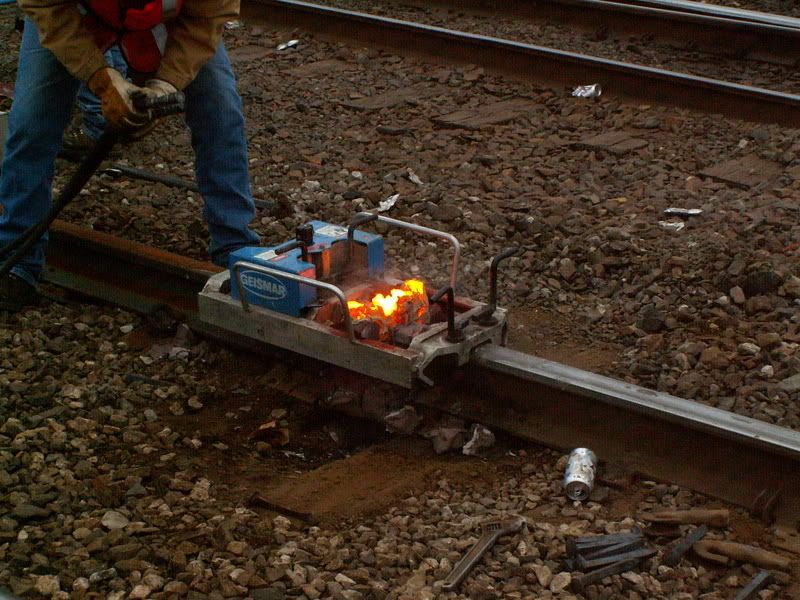

finished weld, prior to grinding.

finished weld, prior to grinding.