Hello all,

It’s been roughly two weeks since I called my “proof of concept” kit bash satisfactory, sadly I have met some major issues in the operation of the car, mostly because of its extreme length it cannot navigate even the broadest curves without derailing.

So now I’ve decided to make a new and improved version of the car as a “master” for multiple resin castings.

Problems I hope/have to remedy this time around:

First and foremost getting the car to run on at least 26" radius minimum (the clubs minimum mainline radii is much broader)

Get the underframe just right.

Make a load for the car.

Perhaps correct the spacing on the second stall of the car. Only if I end up having to modify the underframe at the ends to accept the prototype trucks.

My current plan of attack is as follows:

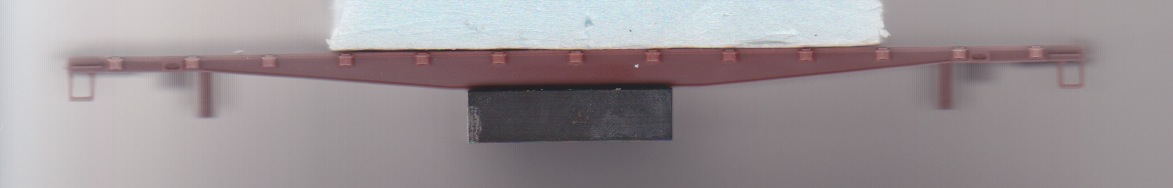

My plan to get the car to run better is use the underframe (the base of of a flat car with the deck removed/not applied) and splice that to length.

Now concerning the running aspect, I see a very real possibility that I will have to cut the underage in multiple locations to get the trucks to clear right. Also I may consider drilling out holes in the center of the trucks to mount them instead of the stock offset bolster holes. Also I may result to making the wheels on the the center axle blind to eliminate binding in sharper radii.

If I do resort to slicing, dicing, and splicing the underframe to work then I will go ahead and remedy the spacing of the second stall at each end of the car to match the prototype.

Proper detailing such as ladders, brake wheel(s), cylinder(s), resvoir(s).

I plan to utilize a underframe off a flat car with the stake pockets and stuff cut/shaved/filed off to replicate the prototypes depressed center as closely as possible.

This isn’t going to be a quick and dirty bash like the first one I’m actually going

on Flickr

on Flickr