Very nice work! Foamcore is also a very versatile product to use in building a structural shell for a number of projects.

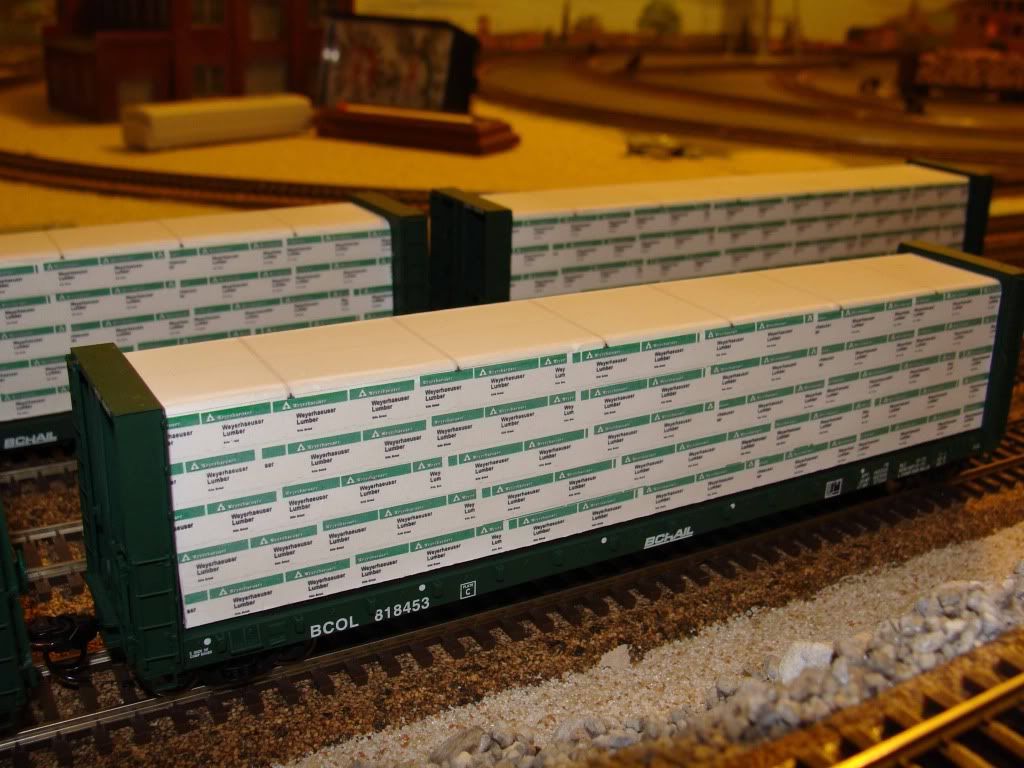

I wound up making my own lumber loads after visiting a vendor’s table at a swapmeet years ago, and noticing the package contained a block of wood cut to fit a Thrall centerbeam car, a printed sheet of lumber packaging material, and some heavy thread for strapping. I thought; “I can do that”…, so I decided to create my own.

First, I used some soft pine cut to size for fitting the length & width of the car side. Using a photograph as a reference, I also noted that most cars are loaded only four courses high to prevent shifting the center of gravity.

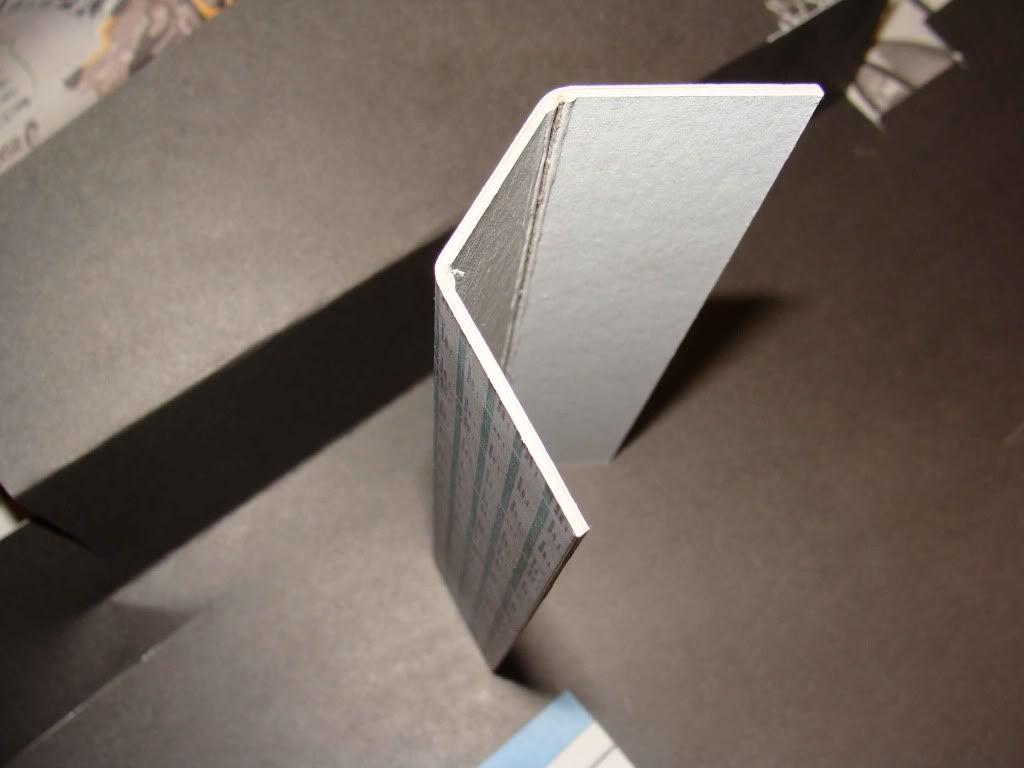

Secondly, using my savvy computer skils, I used MS Word, and setup a table of four rows & ‘x’ columns measured to the size of the piece of wood. Once I set my rows evenly spaced to fit the height needed, I offset the the columns in each row to simulate random stacking. I set the cell border color to a medium grey to denote the individual packages of lumber.

Next, I inserted my chosen brand markings as an image to be easily scaled down to fit inside the table cell. I then copied the image into the remaining cells.

Finally, I added vertical banding and corner protectors to the lumber paper layout using the graphics utility portion of MS Word, so that these items could be moved and ‘floated’ over the top of the table cells.

Note: Pay close attention to the spacing of the tie-down lugs on the railcar for reference. Be sure to extend the strapping beyond the design so it can be wrapped around and hidden behind the blind side of the wood block when assembled with glue.

Lastly, I grouped the whole design layout together, and copied it to another part of the same page, and printed it out.

A helpful tip for added realism is to crumble up the paper somewhat to simulate the wrinkles & creases that occurs with the packaging before gluing it to the wood block. Seal the paper with a U