One industry on my new layout will be a lumber mill. That got me to thinking about the types of lumber on the market. You have both regular boards and pressure-treated. Both are shipped by rail. My questions are: what is the best way to model pressure treated boards, ie get that greenish grey tinit the have? Also once the boards are cut at the mill, are they usually treated on site or shipped to another facility for treatment?

GP-9,

If I may make a suggestion? First find out when they first start having pressure treated lumber,then act accordingly… Just My Thought!!

Cheers,

Frank

i checked into it and CCA actually came into use in the 1930s. My layout will be transition era. So it might be appropriate.

Good For You,Now your thinking,Got ONE,more for You,

CCA,has been used to pressure treat lumber,since the 1940’s,(chromated copper and arsenate),better known as,Chromium Copper and Arsenic…Started it’s use commercially,1970’s,about a ten year span,it is no longer used,it was banned…There are other new chemicals,for that purpose.

Cheers,

Frank

To simulate the PT coloring on the wood, experiment w/ various shades of green acrylics thinned to a wash using alcohol. You only want a green cast and still have some of the “wood” show. Pine or basswood should take the wash fine. Not all mills will have the ability to do the pressure treating, for additional industries you could move loads from a mill to the PT facility and lumber stacks.

Pressure treating of lumber is frequently done at a specialized plant, rarely at the lumber mills. While older treatments were left the wood with a grayish/greenish tone, the wood will often age naturally to a grayish/brownish shade. An easy way to get the color that you want would be to soak bass wood in a mixture of stains ( I used Min Wax in a clean pickle jar), fished the wood out and let dry on a sheet of plastic cut from a painter’s drop cloth. I do believe that you could also get good results with those spiffy stain pens, layering a light shade over a dark one, if you are needing just a few pieces.

Don H.

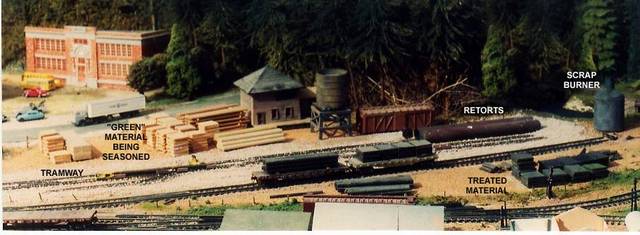

I was graciously allowed to visit Conroe Creosoting in Conroe, Texas about 1982. They produced railroad ties, utility poles, barn poles and posts in creosote and other treatments- I don’t remember whether CCA or penta. The greenish kind. The plant received raw logs- I think by truck ca 1980s- they cut them, seasoned them and then treated them. I don’t consider them a sawmill that did own processing but a processing plant that did own sawing. Sawdust and slash was burned in a regeneration plant to generate steam used in treating process. Had a rail spur for shipping out product- plus adjacent retail/wholesale sales facility.

cogeneration plant, adjacent to sawing facility.

general shot of plant

retorts for pressure treating

My N scale version of plant

You have done a very nice job of showing an entire process in a narrow space! This is also a fine reminder of how many different ways that rail oriented businesses can be modeled. Thanks for the good pictures.

Don H.