I recently remotored two old blue box F7 diesels using the Mabuchi FK-280SA-14200 dual shaft motor. The results have been astounding! These two diesels will easily pull a 12 car (NMRA weighted) train up my 22" radius, 2.62% grade helix as slow as about 5 scale miles an hour without a hiccup or hesitation. Far better than the old Athearn motors with less current draw and a purchase price of only $2.45 each on Ebay. I still have about six more locos to remotor. Unfortunately, all the Ebay vendors previously selling these motors are gone and other sites state this motor is no longer available. Does anybody know of a source where I can still buy these motors?

That is unexpected! As many as there was on eBay I didn’t think they’d ever be unavailable.

I found some listed on Aliexpress, I haven’t bought from them before so that is an unknown.

https://www.aliexpress.com/i/4000371759600.html

Keep us posted!

Mel

My Model Railroad

http://melvineperry.blogspot.com/

Bakersfield, California

I’m beginning to realize that aging is not for wimps.

Item is no longer available.

As there will be at least some of you who don’t know the Mabuchi motor code when assessing replacement types:

https://www.mabuchi-motor.com/product/knowledge/classification/designations.html

They were so cheap I bought 20 of them… I am glad I did.

I cannot believe they are unavailable, they were everywhere.

-Kevin

Hornblower, you can try this one:

https://www.aliexpress.com/i/33049650588.html

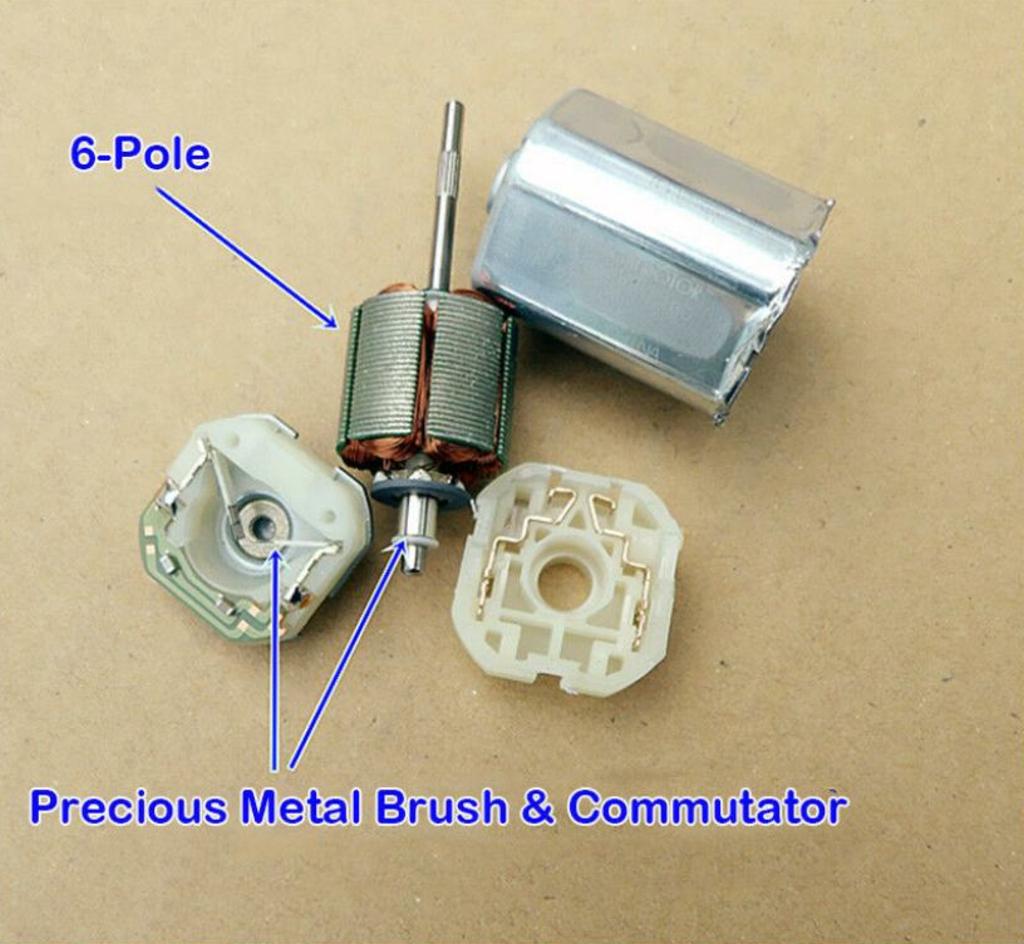

It costs less than 1 USD, so no risk. According to my experience, it comes unlubricated, so add ONE drop of oil at each bearing before use. I bought it just out of curiosity, but it seems to be just fine motor. It has carbon brushes, so it should be durable. Rotor is skew wound (meaning cogging is negligible), therefore it works well with DCC decoders, I tried it and found no issues.

Hrvoje

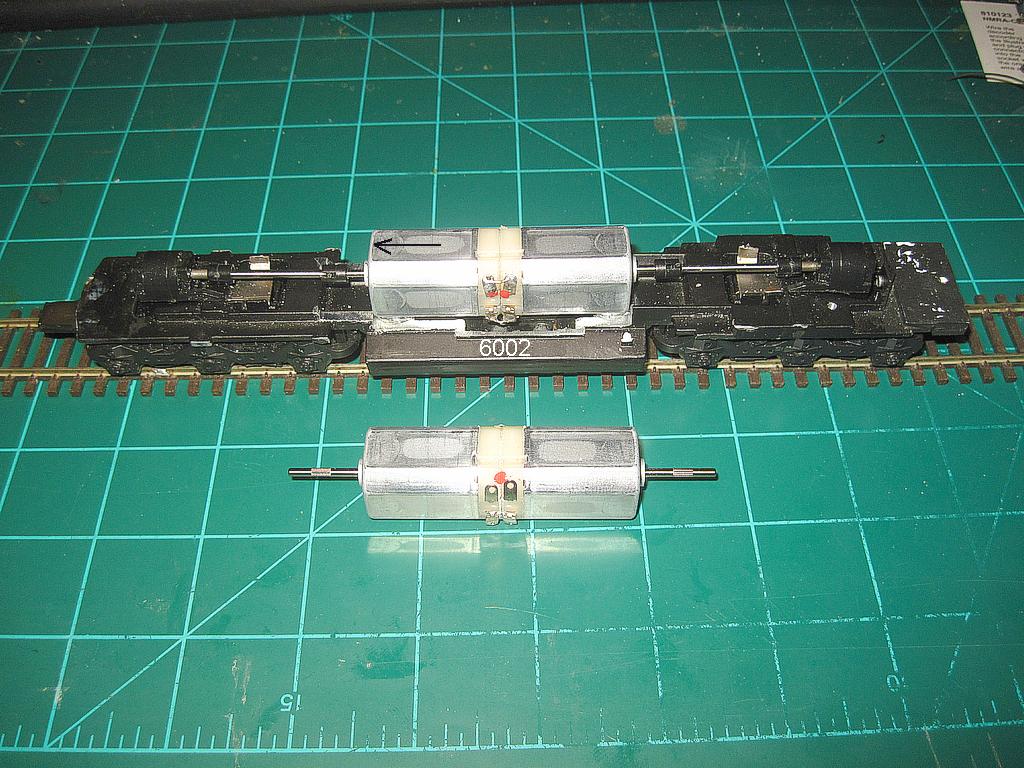

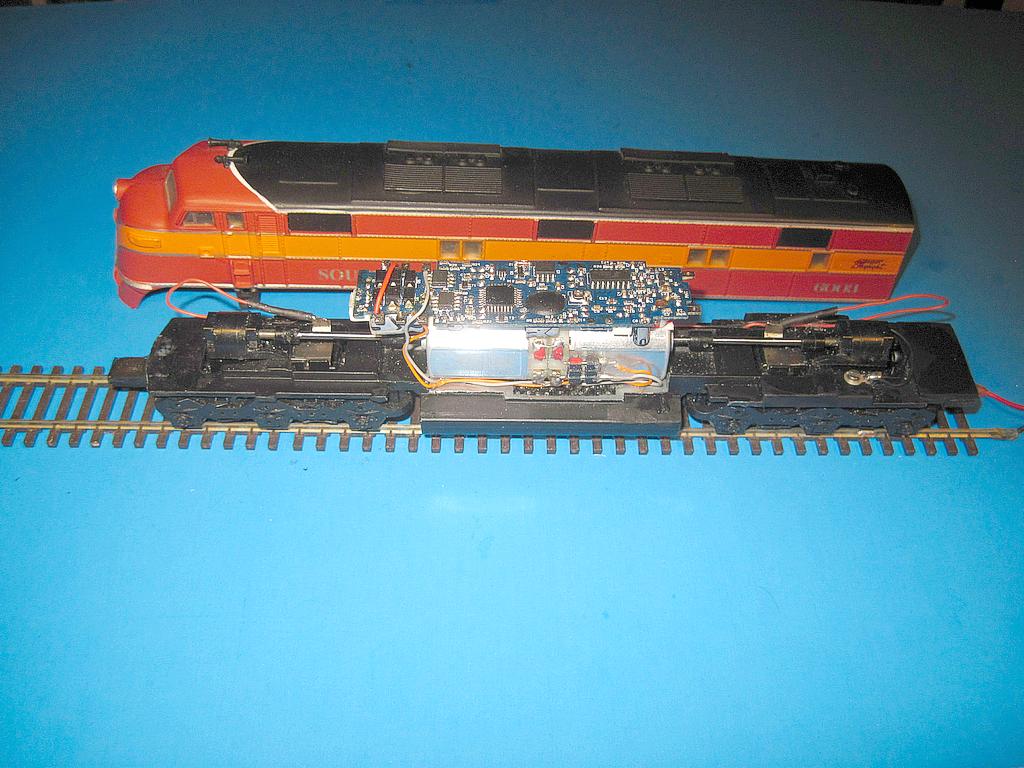

If you aren’t into running at high speed early on before I ran across the FK-280 motor I used a pair of SF-266 motors in an Athearn SD40 frame.

The SF-266 turns at 7200 RPM at 12 volts, the Athearn motor is 12000 RPM at 12 volts.

It required filing the Athearn frame a bit but they work pretty good at about a scale 60 MPH. The dual motors have plenty of power just not real high speed.

My E7s are Athearn SD40-2 frames with Cary E7 body’s weighing in at 2 pounds each. With the 266 motors they have 7 ounces of drawbar each at wheel slip and don’t slow down on my 3½% grades.

I prefer the FK280 but if I can’t find them I’d be happy with a pair of 266 motors.

Mel

My Model Railroad

http://melvineperry.blogspot.com/

Bakersfield, California

I’m beginning to realize that aging is not for wimps.

I forgot to mention another excellent motor that could be used in some locomotives where high RPM is not required. This is Namiki coreless motor, 9000 rpm/18 V, dual shaft, 35 x 16 mm. There are at least two sources: Allelectronics (9 USD, read the only review there [;)]) and ebay (23,95 USD).

I tested one, in Genesis F7, and as this locomotive is advertised as “freight”, I do not mind locomotive does not run fast. But this motor is very strong, runs good both on DC and DCC. It has zero cogging, so with DCC decoder, excellent slow speed performance is possible, as with any coreless motor.

It is heavy and finish is excellent, when you have it in hand, it is obvious, this is a quality Japanese product. I found info somewhere else (I cannot find it anymore) that this motor was meant for some project that was abandoned in the meantime - therefore such attractive price, I assume.

One more thing - motor gives some light sound (high pitched) - I do not mind it, but some maybe will. As I am getting older, I will hear even less from high frequency spectrum, so…

Hrvoje

Unfortunately, neither of the referenced motor information pages on the aliexpress website mention the availability of these motors. If you click on the tab marked “view details and buy” you will then see the note that both these motors are unavailable.

The coreless motor is definitely an idea although the price would get me three of the Mabuchi motors. I’m not too sure about living with a high pitched tone from the coreless motor either as I still have excellent high frequency hearing.

Sorry, I did not see the first motor I suggested is not (hope just temporarily) available.

About the other one, maybe I need to clarify. The sound it generates is not louder or worse than the first motor I mentioned (and this is not noisy), or any other iron core motor - such motors are usually much louder than coreless motors (except maybe Canon, I was amazed how silent this motor is). But as I am used that in principle, coreless motors are (or almost) silent, this Namiki can be heard. But not so much that it would annoy.

What is price concerned - coreless motors are usually more expensive, and this motor is really a quality motor. For 9 USD, I did not hesitate, I bought it and I am not sorry - it will stay in this locomotive, and maybe in some other to come (I bought 5). And with DCC, it will provide running performance that is hard to match by iron core motors, due to zero cogging.

Hrvoje

Hrvoje

You are correct that $9.00 for a quality coreless motor is a great value. However, since I’ve already been impressed with the performance of the Mabuchi motors, I was all set to purchase at least 6 more (6 X $0.85 = $5.10 from Aliexpress). If I only had one or two locos to remotor, I probably would go with the coreless motor. However, a whole fleet of locos equipped with coreless motors could get expensive (6 X $9.00 = $54.00).

As the Mabuchi motors are manufactured in China, I am hoping the the COVID crisis is simply causing delivery delays that can be resolved once the Covid crisis is resolved.

These iron core motors are coming and going in circles, I am sure after a while, you will catch them again. I noticed that already, some of motors I bought were available in large numbers, then dissapear for some time, then come again. It is not easy to find good dual shaft motor, so when available, it is better to grab more and have some reserve for later - iron core or coreless.

Hrvoje

As a potentially very stupid question:

I see the single-shaft version of this motor (used among other things for automobile lock motors) still readily available, often with pre-knurled shaft on one end.

Has anyone tried polishing down some of that knurl if need be, and using a press or staking tool to press the shaft to give shorter ‘double shafts’ (that still appear long enough to take most universal ends or other devices)?

Overmod

Do you think it’s doable?

There is another problem, the 266 is 7200RPM at 12 volts and the 280 is 13800RPM at 12 volts. The Atheran motor is 12800RPM at 12 volts.

Mel

My Model Railroad

http://melvineperry.blogspot.com/

Bakersfield, California

I’m beginning to realize that aging is not for wimps.

You’d have to fit a bearing in the commutator end, and also figure out how to press the shaft through both the rotor and the commutator without crushing the commutator.

–Randy

Randy

It looks like there is a bearing in the motor shell or end bell. I haven’t taken one apart as of yet.

The knurling on the shaft is in the shaft not enlarging the 2mm, it looks like the shaft can be removed through the bearing.

Even if that works it doesn’t change the RPM problem.

Mel

My Model Railroad

http://melvineperry.blogspot.com/

Bakersfield, California

I’m beginning to realize that aging is not for wimps.

The motors I was seeing were 280s with over 14K RPM spec (I found them with a simple Google search on the old motor code). Those seemed likely (to me) to be the single-shaft version of the motors in question.

I suspect you’d need to make a jig analogous to some of the ones for vacuum-cleaner-motor service: something holding the armature pole sections and the end of the comm solid and square as the press pushes the shaft. It would be interesting to see how Mabuchi gets these shafts located and then trues the armature up for high RPM… I have a grim suspicion the armature is pressed on the shaft before the commutator, with the electrical connections made afterwards.

It’s possible we’d have to check and adjust rotating balance of the armature after displacing the shaft. Normal static balance on knife edges is a start; I suspect it wouldn’t be rocket science to build a dynamic rig that would mark imbalance as a spot on each edge of the armature stack for a little spot grinding…

I don’t think it’s worth the effort because of the low RPM of the 266 motor. There are several dual shaft motors out there that turn at 7200 RPM, the Athearns need 12K RPM to run at normal Athearn speed.

Also as I have shown in the earlier post pictured above you can put two 266 motors back to back in an Athearn frame, double the power but still at reduced RPM. I have two Athearn SD40-2 frames with dual 266 motors installed and they run very good at slow speed, about scale 50 to 60 MPH max speed because of the lower RPM.

I guess we will just have to be patient and wait to see if the FK-280SA 14200 returns

Mel

My Model Railroad

http://melvineperry.blogspot.com/

Bakersfield, California

I’m beginning to realize that aging is not for wimps.

This Kato-style motor is available:

Might work.

I ordered one of those before they became unavailable. It would work but it doesn’t have the same power the stall current is 800ma. The FK-280 stall current is 1.4A. The FS-266SA is 1.12A. The Canon EN22 is 1.10A. All at 12 volts.

The FK-280SA 14200 motors are listed as available off Amazon but pricy.

I think they will become available on eBay if we are patient.

Mel

My Model Railroad

http://melvineperry.blogspot.com/

Bakersfield, California

I’m beginning to realize that aging is not for wimps.