Ok, I know about the Athearn rubber band drive, but I have never seen one assembled. I have a bunch of the trucks with the large axle for the rubber bands. My question is related to how the rubber band goes around them. Does it just loop down and go over the bottom of both axles, or is there supposed to be one rubber band per axle? If two bands how does one get them over the axle without disassembling the truck?

This old drive system had solid driveshafts held in bearing posts. The rubber bands ran over the driveshaft and down around the large axles. Each axle had a rubber band on it.

You have to disassemble the truck and disconnect the drive shaft from the motor to install new rubber bands. I don’t remember the procedure, but I do remember that it wasn’t difficult.

I still have my old rubber-band powered loco stored away. It was my first HO scale loco and I ran the heck out of it. The rubber bands are long gone now. I had a paper route as a kid and used small rubber bands to roll up the papers. Those rubber bands fit the locomotive perfectly! I had thousands of those rubber bands! Wish I could remember what size they were, but that was almost 50 years ago!

Good luck fitting new bands on the axles. It isn’t hard to do, just time-consuming.

Darrell, quiet…for now

Probably looks like something similar to this, http://hoseeker.org/assemblyexplosionAthearn/Assembly%20Explosion%20Athearn%20%20Hustler%201991.jpg , except with two rubber bands per truck.

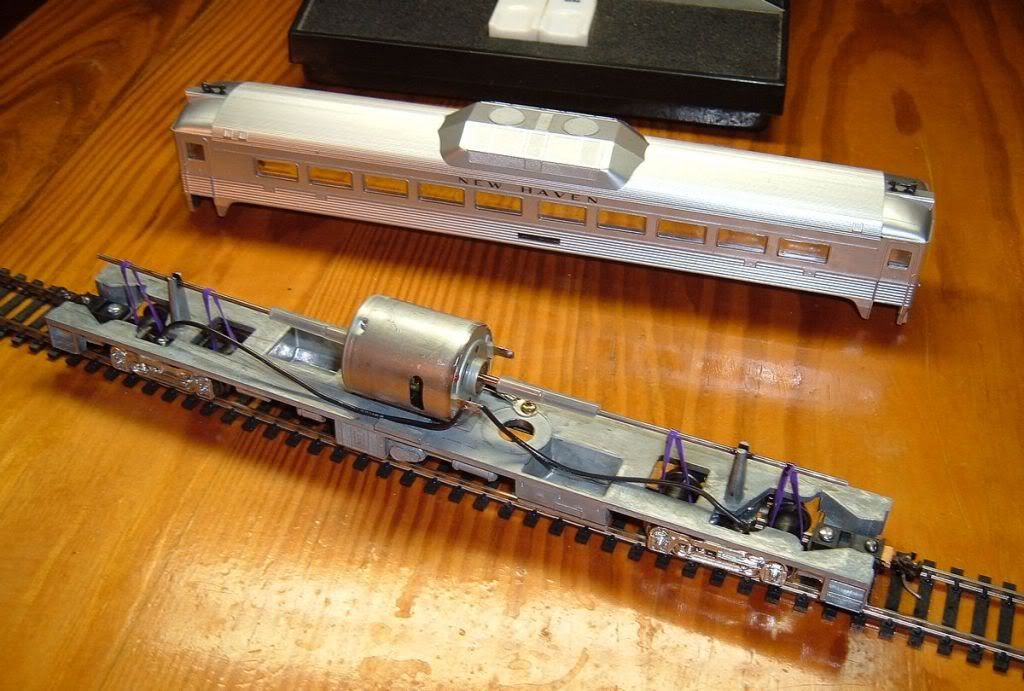

I had an old Athearn RDC with rubber band drive. The pully shafts were longer and I think each had a steady bearing at the end to keep it supported. I suspect the F7 is similar.

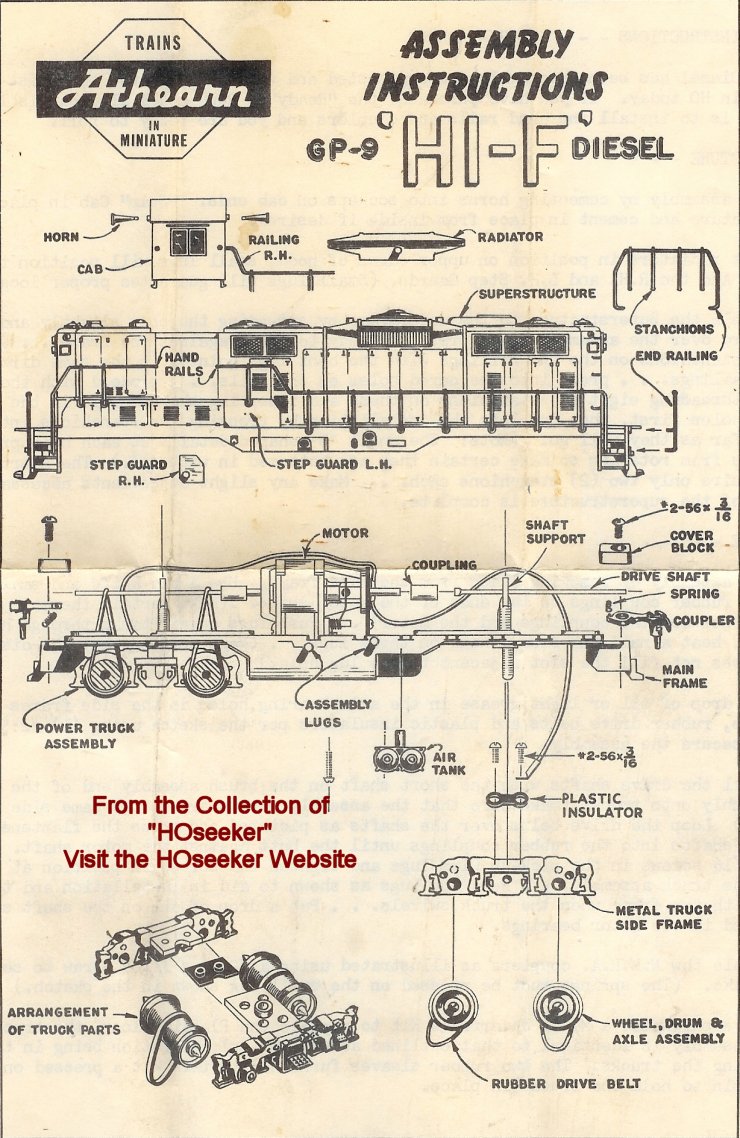

Here’s a Hi-Fi GP-9 instruction sheet with a good view of the band arrangement.

There are hair bands made by Goody you can find at any Wal-Mart that are more like a stretchy vinyl, and don’t rot like traditional rubber bands. I’ve had some on an old Budd car for a long time without any deterioration.

One thing that is hinted at in the instruction sheet but not mentioned, is that all of the rubber bands must go around the drive shafts in the same direction; coming up from the back of the rear axle to the right-hand side of the drive shaft and down to the front of the axle. At least, get them all the same. Otherwise, your axles will be turning in different directions, and your loco won’t move very well. [:)] Been there, done that.

Having both trucks turning opposite directions is a good way to find out if one end is more heavily weighted… [:-^]

Athearn still lists the rubberbands as available. Part number 90101.

I had a couple GP7’s and a RDC as well as a pair of Hustlers with the Hi-F drive. They ran like a bat out of hell. The bands at times stuck to the drive line making for some interesting happenings.

I recently got an old Athearn Hustler from a friend and I am totaly rebuilding the drive from rubberbands to gears. I found out that the Athearn 4 truck gear sets will fit into the Hustler with no problems. So out with the rubberbands and in with a new NWSL small can motor, gears from Athearn, a Digitrax Decoder and Leds for the headlights and a yellow becon. Was thinking about putting a sound decoder in to it later like West Port Terminal did for his small switcher that he did. Just trying to find an engine sound that would fit an Hustler type engine. Any Ideas? Kevin

That little loco looks like one I had back in the 60’s, except that mine had gears instead of rubber bands. I remember that it traveled at warp speed!

Thanks for the replies. I know what I am doing now.

Throw it away (alright, convert it to a dummy) and forget about it!

Mark

What would be the fun in that? That is a pretty limited view of the hobby. With entire fleets of Stewart, Genesis, and Proto 1K & 2K, I certainly don’t need this as a model to use on a layout. Consider it like I am the curator of a museum and want all the exhibits to be in the best possible condition.

As should be evident from the drawings taken from that wonderful HO Seeker website, the truck has to be partly disassembled to get the rubber band in place. And that was always an invite to the young modeler to get the wheels reversed and other havoc.

What is or was surprising about the old Hi-F rubber band drive is that the locomotives actually pulled pretty well. But there was definitely a point above which adding more weight was counterproductive; I bought a GP7/9 where the guy had added all sorts of lead weight to the frame and the thing would simply not run at all, I mean zero. The rubber bands would slip, well before the motor could become overheated.

Two real negatives to rubber band drive are the sound – a sort of insane grandfther clock ticking sound where the shell acted as amplfier – and the speeds, particularly of the Hustler. When I would double head my Athearn rubber band F7 with my PennLine geared F7 it would moderate the speed and added considerably to the pulling power. So assuming you can live with the funny sound, mating the rubber band drive engine with a geared engine should address the excess speed issue. And you’ll be running a piece of model railroad history – for better or worse.

Dave Nelson

I think it would be great to run a four unit set of rubber band drive units. My recollection is that, besides pulling pretty well, once you got “up to speed” (and, no, I don’t mean 170mph), they ran really smoothly.

Ed

ANother benefit - back when Athearn offered the choice of the rubber band “Hi Fi” drive or gears - the Hi Fi locos had 8 wheel pickup, the geared ones, only 4 - 2 wheels on each truck. So for best operation over dirty track and insualted frog turnouts, the rubber band drive was the way to go.

Best ones yet were the RDCs, at full throttle a sudden stop would cause about a 2 foot lurch as the rubber bands stretched and then pulled back. Instant death for any HO scale apssengers due to excessive G forces. Fun stuff in the midst of mundane scale speed operations.

–Randy

If you want to make your Budd cars or F-units crawl, try this motor.

It’s a 24 volt motor, so it really slows it down. Full speed can’t be more than 60smph.

Hi!

These Athern F & GPs were my first HO locos back in 1961! For the money, they were terrific. They were OK for pulling trains but slow speeds were not their forte. But, if its drag racing locos you were after, man they could fly!!!

As I recall, the bands had one half twist on them, and you had to make sure they were all twisted the same way to assure each wheelset was going in the same direction. If you need new bands, a good office supply store should have rubber bands of the same or close to the same size.

Enjoy,

Mobilman44

This evilbay lot has some parts for Band drive, if you need any.

One thing that could reduce the speed and add to the power, if you could find one, would be the old Pittman conversion unit for the Hi-F drive. Shortly after the rubber rand drives came on the market, Pittman put out a conversion unit (for the 4-axle locomotives) with a geared-down driveshaft, which passed through the motor, and was about 1/8" in diameter, so it didn’t use the shaft support from the original drive (you just snapped that off the frame). The gearing more than compensated for the increased driveshaft diameter. The unit reduced the breakneck top speed to something more realistic, and improved the pulling power.

I had one of these in an F-7 back in 1961, and as I remember, it was not any noisier than the stock drive, which was remarkably quiet for the time.

Another thing that can improve the running qualities of the Hi-F drive is to run two powered units together. The start and running is much smoother, because the two units compensate for each other by smoothing out the surges caused by the flexing of the rubber bands. And the pulling power is vastly improved!

The actual gearing gave a four to one reduction. The 1/8" shaft was twice the diameter of the Athearn shaft. Total reduction was twice the Athearn ratio which was about 7 to 1. Hey, at 14 to 1, a Pittman re-motored Hi-F drive should MU with a lot of our current diesels.

And to avoid confusion for people who haven’t seen one of these, the shaft didn’t actually go through the motor itself, it passed above the motor. It passed through the entire motor/gearbox assembly, though.

Ed