Got a gift of the New York Central 6-30103 system. It ran great at the holidays. My grandson wanted to get it out again. Ran fine. He ran it for hours. The next day it hits the bump on the decoupling track and gets hung up. I think that rais

ed area was always there. It’s almost as if the engine isn’t riding as high as it was the day before. Engine gets hung up even if power is off and I just try to push it over the bump in the uncoupling track. Would appreciate advice as my grandson thinks I can fix any problem.

Welcome Tom!

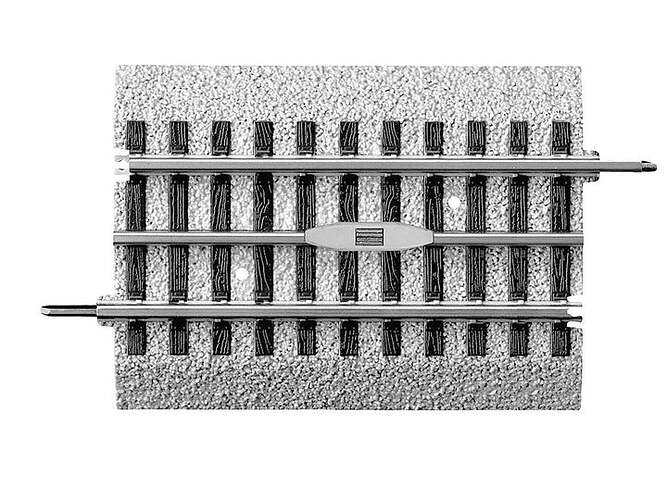

I suspect the problem may be with the decoupling track but as richotrain says a photo would be helpful. It’s possible that something may have worked its way out of alignment on the decoupling track due to the heavy use. Also I’d say do a close inspection on the underside of the engine just in case something’s gotten out of alignment there. Mind you, these are just guesses on my part.

1 Like

If that’s the same part, you can see the electrical part underneath has massively overheated and lifted the middle section. Remove it and pitch it. Get a new one or a straight piece of track.

TOC

yeah, it looks like the uncoupler magnet must have been left energized for way too long and overheated, melting the plastic. Not much you can do except purchase a new one.

-El

Hey, you don’t need an uncoupling track if you’re like me and do “Hand O’ God” switching!

Looks to me as if it’s just the plastic that’s warped, and the magnet poles are still ‘where they were supposed to be’? Does the magnet still work?

If it does, just cut away the plastic of the magnet ‘cover’ until you can get the face of the magnet poles to third-rail level. Then mix up some JB Weld to fill in and level the path of the ‘third rail’, and smooth it with something like a small plastic spatula or putty knife dipped in corn oil. That may look a bit Penn Centralish but ought to be easier and cheaper than confessing defeat…

1 Like

you do make a strong argument, It probably can be done.

JB Weld is great stuff, just used it recently to replace a failed solder joint on a Lionel 254. I don’t know how well it would hold up to much heat, but it’s probably better at withstanding a little warmth than the ruined plastic it would be replacing.

-El

I have used JB Weld and JB Kwik Weld many times to make repairs. It is outstanding stuff.

Rich

You folks are making this much harder than it needs to be.

If this track was ever on carpet…think about damage and fire. If it melted it that badly…I would make sure it was in the trash.

Cut? Epoxy? Maybe, if poster has the skills and equipment.

Then, cut and remove all wiring in case it shorts again, or the button sticks.

Holy jumpin’ catfish.

TOC

1 Like

You forgot to say ‘Keep it off my lawn!’

Seriously, that’s nowhere near serious damage… more like someone kept it on a bit too long and the plastic warped. For the sake of completeness he could show us the bottom side to see if there’s any compromise in the wiring that might expose the dread 18 volts AC or whatever. Yes, he should check the coil with a multimeter to be sure it hasn’t shorted between some of the windings. But at least check before you chuck.

maybe. Can you guarantee the integrity of the field insulation?

Damage like that, personally I would never tell him to run it or repair it.

I am glad you took on that role!

TOC

Hell, no, but checking against a stock value for a ‘good’ coil will tell you if any of the coil turns are actually shorted.

And yes, I’d be happier if he left the ‘repaired’ track section magnet de-energized, and just ran trains over it.

![]()