Dear Friends

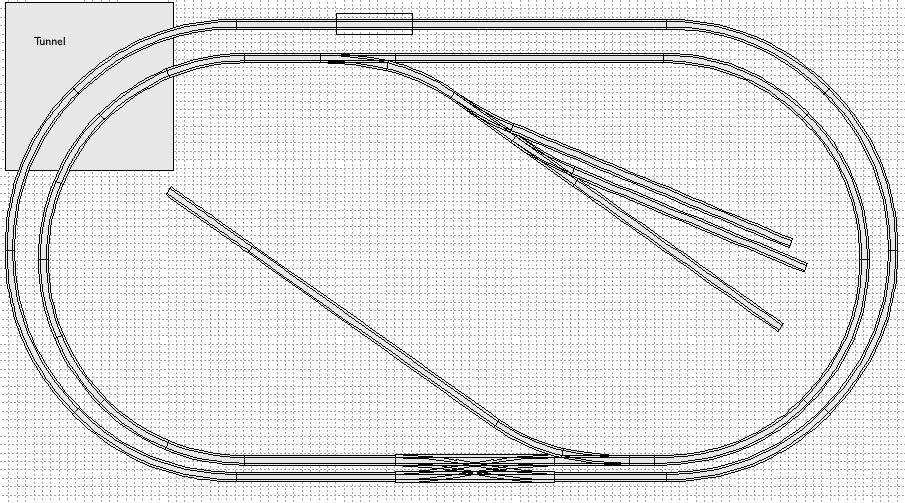

I’m finally getting around to building an HO layout for my four-year-old son. Its base is a 9’ x 5’ ping-pong table. The track is going to be simple: two concentric loops with a yard and one or two spurs. The outer loop will use a three-precent foam incline from Woodland Scenics. The layout is going to feature an 18" truss bridge and a small mountain tunnel. It will use the Shinohara double-crossover, which I’ve already purchased.

Here’s where I am now:

And here’s my general plan for finishing this project:

- Cut out space for bridge

- Paint

- Lay down cork roadbed

- Lay track

- Wire track

- Install tortoises (4 on double-crossover, 1 on other mainline switches)

- Ballast track

- Tunnel/Mountain

- cardboard strips

- plaster cloth

- joint compound

- paint

- Apply ground cover, trees, and structures

Is this the general order I should follow, or am I missing something? I’m not used to doing hands-on work like this and I’ve put off this project for more than a year. I’m accustomed to working with computer-based tools and being able to fix my mistakes easily.

Thank you very much for educating me about model railroading.

Sincerely,

Jaddie