Similar to the most recent MRR project layout, I intend to use plywood rather than 1X4 for the outside framing and inner supports for a 4X8 layout. Then eventually add to the end to bring it to 4X10 and finally 4X12, sorta in stages. I’m thinking to use standard pine, will paint it, don’t feel I need the hardwood plywood. I’ll probably go 3/4 inch or close like 11/32 or something, cut to 4 or 5 inches wide. Appreciate any advice. Thanks! Have fun!

The surface is not as important as the structure and glue. Typically the hardwood plys have good glue. Otherwise look for an exterior or marine grade. You might find that the birch face is the most ecomomical.

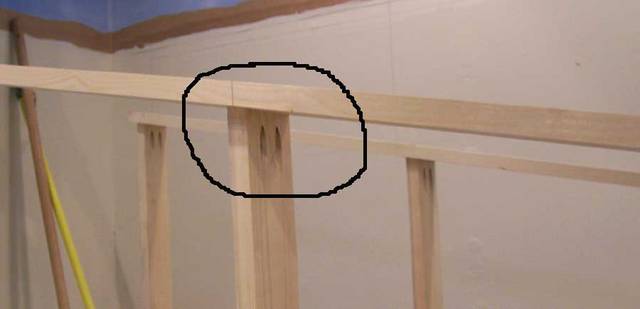

You want ply that will take a screw from the end. Some say you can’t do it, but if the glue is good enough and you pilot drill the ply to the size of the shaft without the theads or a 1/32 smaller, it will hold nicely. If you have air tools, an 1 5/8" 1/4" crown staple makes assembly a snap.

good points SpaceMouse. for the ends or other joints I was actually thinking using a small cleat to accept screws from both pieces of plywood being joined, probably two screws and glue. I think I’ll use 1x3 for legs though. thanks!

The benchwork of a layout is like the foundation of a house. Trying to scrimp on it can only lead to problems later on. Using plywood ripped to dimensional lumber sizes is a good solution to the problem of finding good dimensional lumber. I would recommend using the higher grade/quality plywood like a birch veneer 3/4" plywood or some kind of cabinet grade quality. These are meant for using in building cabinets and furniture. As such, they do not have voids in the sheet between plys, something you can come across in lower grade plywood.

jktrains

If you use pocket hole joinery, you won’t have to worry about screwing into the end grain of the plywood. Trying to get a fastener, nail or screw, to bite and hold in end grain of lumber or plywood will result in a weak joint. Take a look at http://www.kregtool.com/products/pht/index.php if you want to learn about pocket hole joints.

I assembled all of my benchwork using pocket hole joints. An added bonus is the ability to remove and relocate pieces of benchwork at will with no problems.

Don Z.

Gary:

I built my layout using 3/4" plywood cut to approximately 3" wide. I have an around the walls setup so I set the width at just under 24" to allow use of 2’ wide foam.

I precut all cross members and added 1x2" nailing blocks on each end. I then assembled the sections in 6’ lengths. I used glue and air tools for assembly but screws could be used.

Since my trainroom is fully finished I did all my cutting and assembly in the garage and moved the modules in when the glue dried.

I would suggest 7 ply birch available from Home Depot or Lowes… BEWARE… HD seems to stock to types and one is of poorer quality. Here in Washington the cost is $39 a sheet… three sheets provided approximately 80’ or benchwork…

I hope this helps

Best regards,

Roger

I too am a fan of pocket hole joints. I learned it in my woodshop, but used it for the railroad and loved it. I used the least expensive Kreig and square drive, self tapping screws with a flat bottom that were made for pocket holes. If you use normal screws which are cone shaped on the bottom they will split the wood. The proper pocket hole drill bit is the most expensive tool and the most important.

I too have holes in my pockets … oops … wrong thread [:)]

Pocket holes for wood … yep love em’

Regards,

I’m not the most experienced modeler, but I don’t really understand why ripped plywood is better than standard 1x3 or 1x4 lumber. Marginally cheaper, perhaps, but you’d better have a redial arm or table saw (and 4 hands) to rip it accurately. I’ve been using 1x4 clear pine framing with 5/8" plywood and 1" foam. So far so good! All joined with standard (cheap) drywall screws - just drill pilot holes and split wlld issues are minimal.

I switched to plywood years ago and won’t go back. I’ve found that plywood is far more stable then 1x pine. As for the construction and milling issues, I will admit I do have a fully equipped woodshop. I’ve found with tight fitting joints, good quality carpenter’s glue, and (here’s the key) air driven nails, extra blocking is not needed.

Even using birch ply, it’s cheaper then clear pine - my last visit to HD 1x4x8 clear pine was nearly $7, and #2 pine was about $3. The same piece made from 3/4" birch ply is less then $3; 3/4" AC ply is about $2.50; and 3/4" BC ply is just under $2.

Nick

A good grade of plywood, I’m talking about 3/4" in A/C or B/C fir, sanded underlayment PTS, and birch or luan these should be 7 ply, Are far more stable than any 1x4 pine. Many locations don’t have decent #2 or even select for that matter, readily available. A good example is look at the crap sold by HD or Loew’s. Some of their #2 isn’t suitable for pallets let alone benchwork. Those more discriminating in the stability of the benchwork materials would be ones to prefer ripped 3/4 plywood over pine.

As you note fastening pine is simple, drill and screw. Plywood should be cleated or pocket screwed. Some say they no trouble w/ pre drilling and screwing into the ends of ply joists, even a good ply can delaminate over time by having the constant force acting to separate the plys. I have rehung hundeds of cabinet doors that had the hindge screws doing this. This is on very good cabinet grade ply. Glad this old method of face frame is out.

So this is really just another matter of choice. I work w/ wood on a daily basis and I guess I’m lucky to have many quality lumber yards and distributors in my area. I acually prefer 1x pine for this purpose though.