A little more on tuning this model’s drivetrain, some of which may translate into similar arrangements in other brass diesels.

The main issue with brass diesels tends to be noise from the driveline, which the brass sheell tends to amplify. In extreme cases, you’ll also have binding and even get the driveline hung-up. What it comes down to is getting the driveline running true, straight, with a little slack but not enough to create slop.

This model uses a very typical driveline, the components of which are available from NWSL and other vendors. The shafts are either brass - as came with the kit - or stainless or other steel as NWSL supplies.The cups and balls – what would be U-joints on your vehicles driveshafts – are slippery engineering plastic.

What’s the right amount of slack? Hollywood Foundry, an Australian custom chassis mfg, recommends around a 1/2mm IIRC, in other words, the driveshaft should be 0.5mm shorter than the distance between the ends of the shafts it is to couple. Obviously, you sometimes need to fine tune that small a measurement, even if you can accurately create the needed shaft. This can be done by filing the end of the shaft.

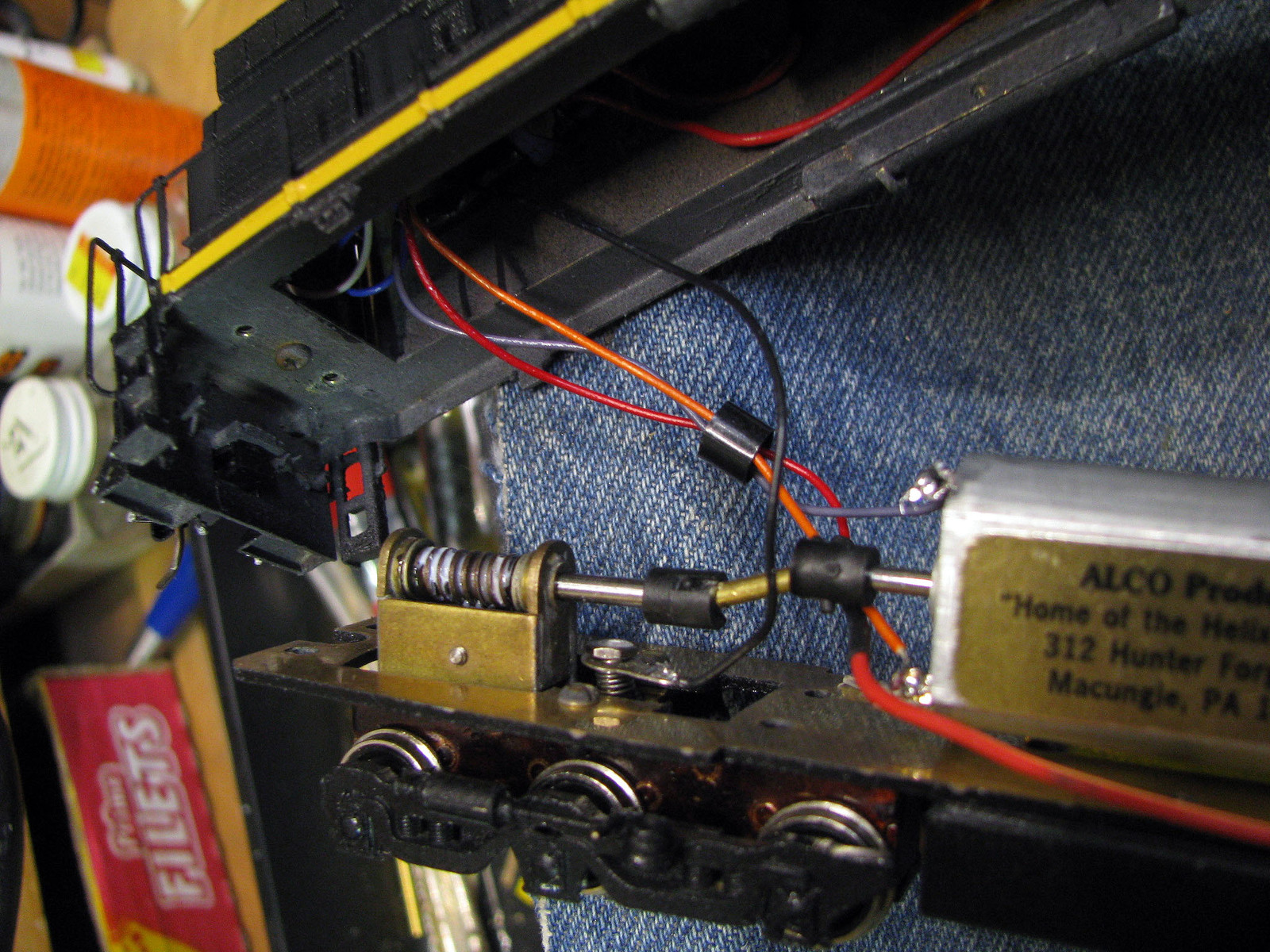

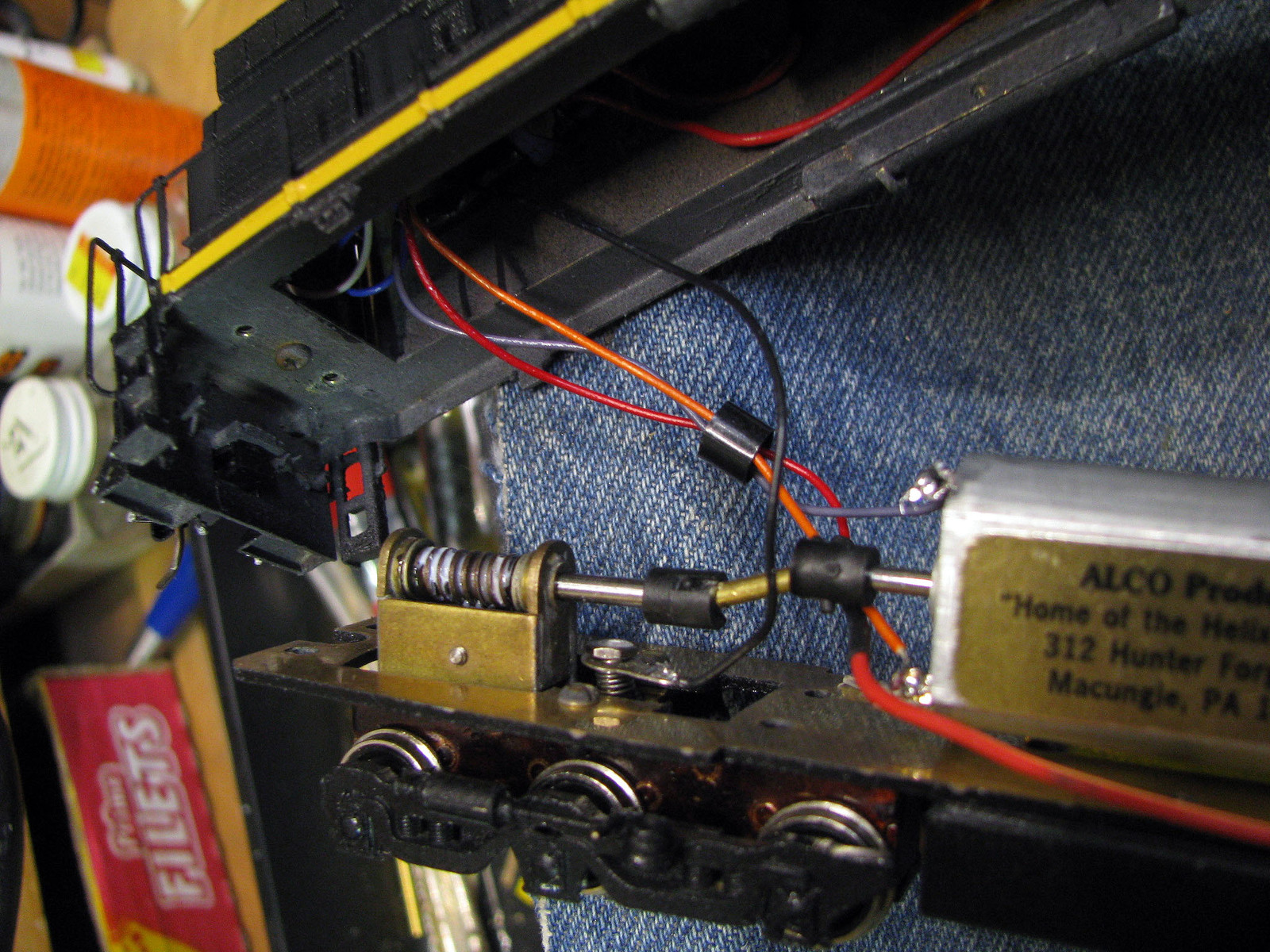

After getting everything else pretty much squared away I tuurned back to quieting the drive. With all the back and forth testing, plus break-in running, one end ended up with too short a shaft. I made a longer one and that helped. The other end was somewhat different. The shaft fit well enough, but the angles/offset of the driven shafts was pretty extreme. Here it is before I fixed it.

The solution? In my first DL-535, I went to trouble of tilting the axis of the motor, angling it to help lower the output shafts to be better in line with the shafts on the truck gear towers. I wanted to leave maximum space for an eventual sound install. Sound keeps getting smaller, so it was less of a concern here. I can still go

Mike:

I was going to say that the offset on that drive line was a bit extreme but you beat me to it! Your solution was exactly what I was thinking.

I have yet to venture into brass although I have been tempted many times. Your example shows that addressing the downsides of brass locos is quite doable.

Nice work!

Dave

Dave,

Happy you enjoyed it. It’s my second brass loco build. Hard to find these kits or others like them, but well worth it.

I wanted people to know there’s no reason to let them gather dust. Life pretty much got in the way of a lot of things I’ve been working on over the last couple of years, which I’ve needed badly to do now to counterbalance and clear my head to chill from my writing. Don’t be intimidated about building one of these kits if you get the chance. Get some practice with basic soldering skills before you plunge in if that’s an issue. Other than that, this isn’t rocket science. The parts are very high quality and fit well with minimal prep.

I’m even now starting to think I should bug PSC about making more, it’s been that much fun. It’s pretty neat to hear it transformed from the rattling hulk it was on Saturday to a pretty darn good loco as I go through it and adjust things. Not quite as quiet as I want it to be yet, like 60 is now, but give it time…[;)]

And how about another pic of 64 on the plow train. mwhile we’re here.[swg]

I often run my DL-535s together on long trains, but they tend to tie up the line because of siding length limitations. Been running one on a passenger train, where they always have plenty of TE to handle things. One on a freight has it limits, despite being heavy and a great puller with 12 wheels turning. She’ll shudder and buck when you reach the limit.

When building them, I noticed the fuel tank would provide a great space to add more weight, but I didn’t thinking this wouldn’t be an issue. Now that I need a bit more TE, I decided to drop the fuel tank and open it up to see what I could add easily. I managed to squeeze in 32 grams, bringing the overall weight to 335 grams. With a little extra power, she does her work well, straining but able.

I figured I’d mention this as there are many of these models out there, many which were assembled. The owners may not have realized how easy it is to use the fuel tank to add weight. It’s possible that assembled models did have weight added at the factory, but I suspect not. There are just two screws holding the tank in place. I managed to unsolder one end and carefully opened things up. On reassembley, I decided to use gap-filling CA to limit the heat damage to the paint. A shot of matching satin black and I was back in business, although there’s very little showing if you’re careful when opening up the tank if you do have locos in WP&Y paint that is more difficult to match.

I owned 2 models of the not kit versions, one of the members of our club did not believe there were narrow gauge Diesels, well, there ya goes, guy as I ran them around the club’s NG line. We would have modern run sessions and that was my answer. The club had to move out however years later. My personal layout is themed 1950’s so no modern diesels,…I sold them…DOH! hard to find models and I did that. But I’m sticking to my ribs on my theme and still kicking my rears on that…heh. PSC had a bunch of parts for the model in Walthers and in the catalogue, I have a set of side frames still. Takers anyone, no real plans to return to the DL’s. The DL535’s were ALCO based Montreal Locomotive Works, in Canada of course.

I’m real glad I held onto these kits for years. It made having them affordable, one of the ways I saved money accumulating. I’m kind of flexible on era, the layout is big enough I can “backdate” the look to various eras. A lot of stuff stayed the same, so easy enough to look OK to me to run them alongside C-19s[:D]. I also was exposed to modern narrowgauge in Europe, so to me it’s totally plausible building something the Rio Grande might have done if things had turned out differently.

But I feel your pain from letting those things go. They’re gutsy, really need 24" min R, but do they do the job. I may weight the other one, too, although no reason. Togheter, they easily handle 20+ cars up 2.5%…and all the non-Blackstone trucked stuff is just not as slippery, I think 24 cars was the max, and they still could handle more, just makes no sense.[(-D]

PSC does have some parts, but get 'em while you can, I suspect it’s over runs from the several differents runs they did and won’t be re-run except for things people are likely to buy for repair, like horns, that fit in with the more regular cataloged stuff.