I’ve had a pair of PSC HOn3 Kit-#10664 sitting on my shelf since I purchased them from PSC at the 1996 Durango National Narrow Gauge Convention, aging until they were ripe to start moving freight on my under-construction layout. I model the Rio Grande, with Durango as a dual-gauge interchange between SG and NG. There’s a bit of standard gauge main with some switching and main line running. Most of the layout is narrowgauge, representing a much busier Silverton Branch. There, the D&RGW interchanges with my Silverton Union Rail Road, which is an amalgamation of the three little lines that went up to the mines from there.

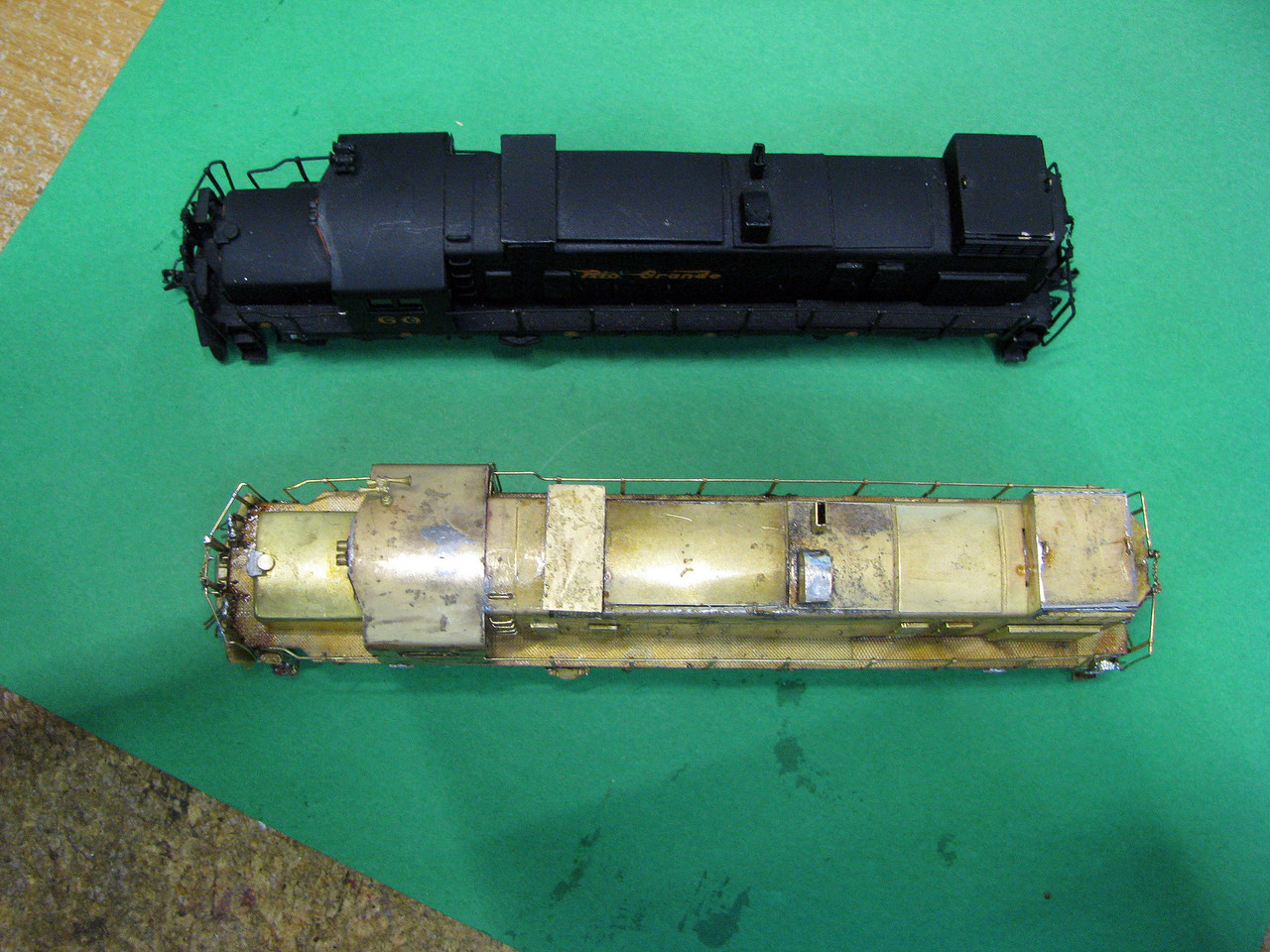

I have 4% grades on 24" radius curves, so hauling tonnage uphill to Silverton is a challenge. I do enjoy my Blackstone and brass steam equipped with sound. But I really enjoy narrowgauge diesels, too. I want to eventually do a post on the entire NG diesel fleet, but here I’m going to discuss building one of these brass PSC kits, which represents the WP&Y 100 class Alco/MLW DL-535E locomotives purchased in 1969.

If the Rio Grande’s NG lines had warranted additional investment, instead of shut down and salvage as happened, the just might have acquired modern diesel power very similar to the WP&Y’s 100 class C-C locomotives. The DL-535 weighs less than a K-28, but provides nearly the same starting tractive effort as a K-36. Despite delays in the acquisition process, the first of at least two was finally delivered after some 16 years.

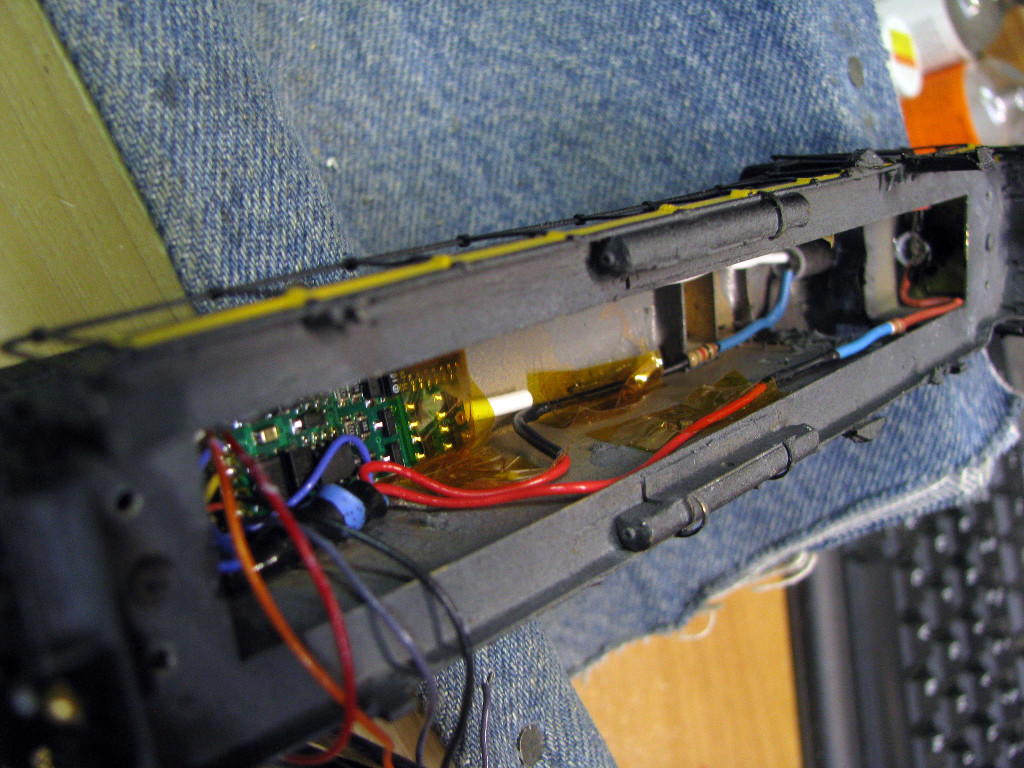

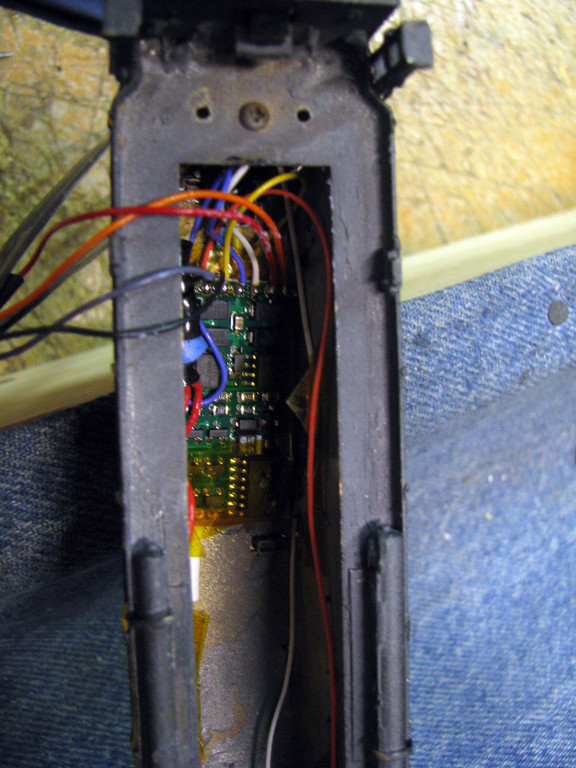

Some may have seen various pics of this build, which I started on last Wednesday, posted in the last Weekend Photo Fun. I won’t repost those images here, but this is the link for reference:

http://cs.trains.com/mrr/f/88/t/210155.aspx

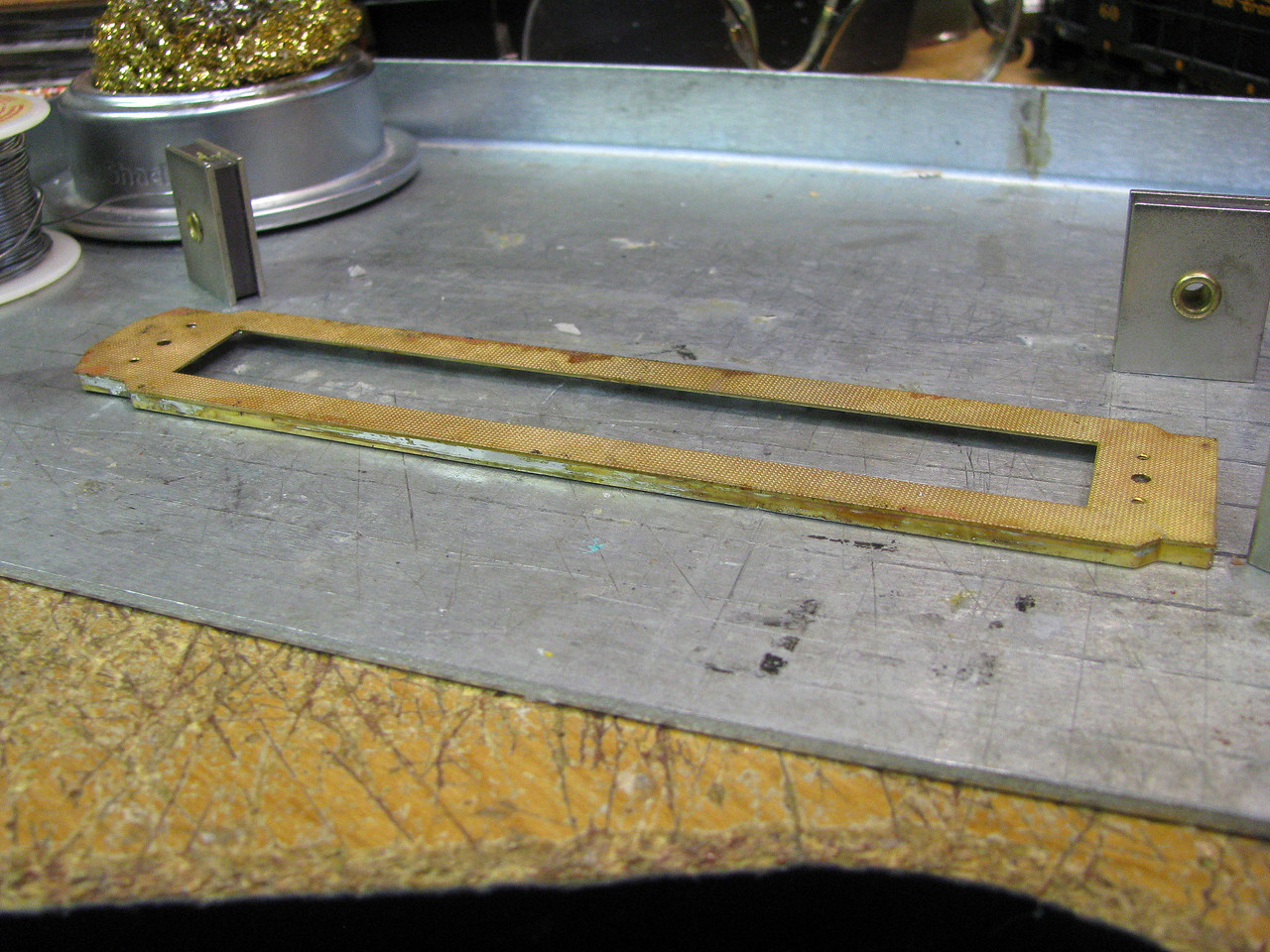

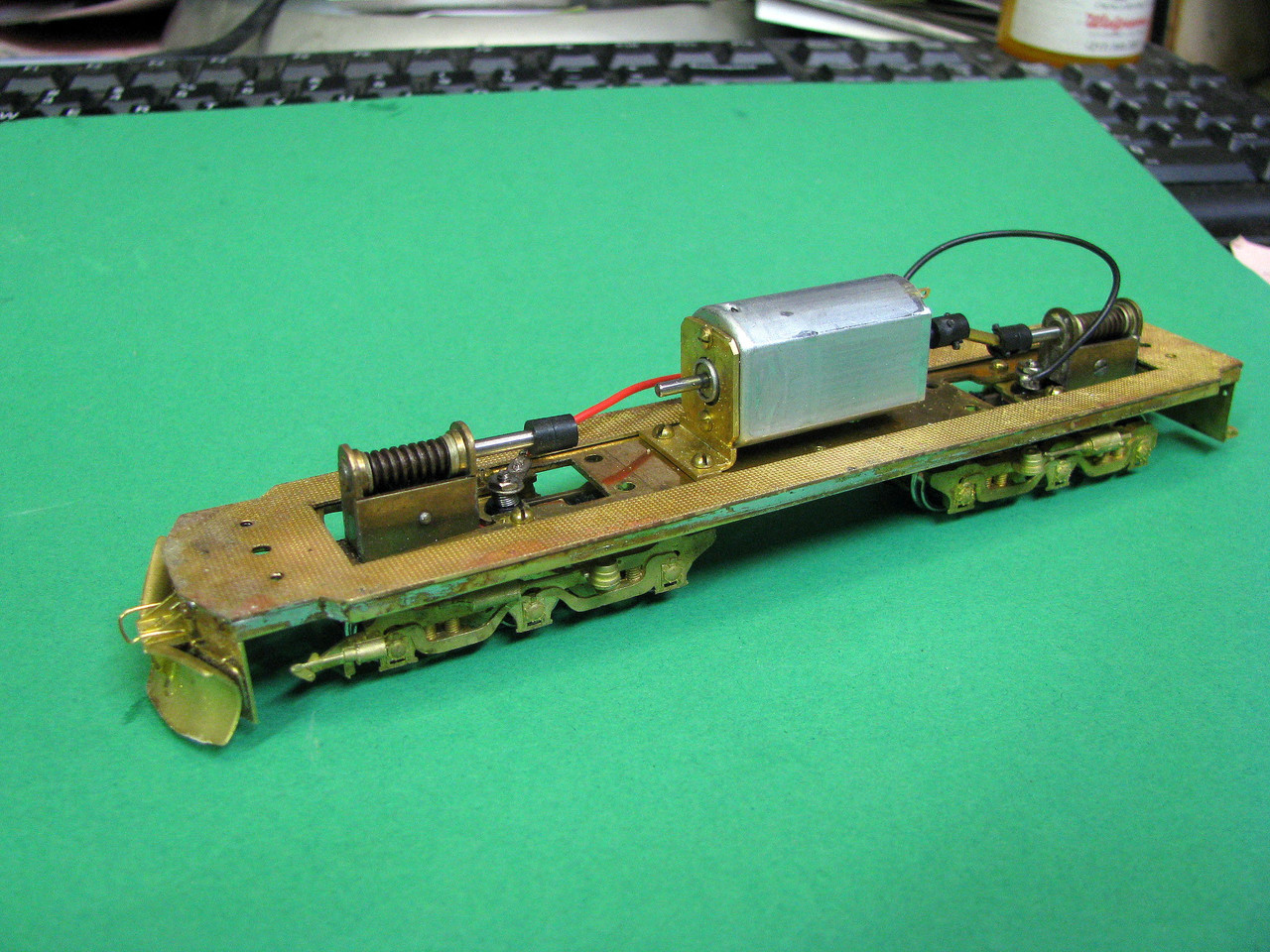

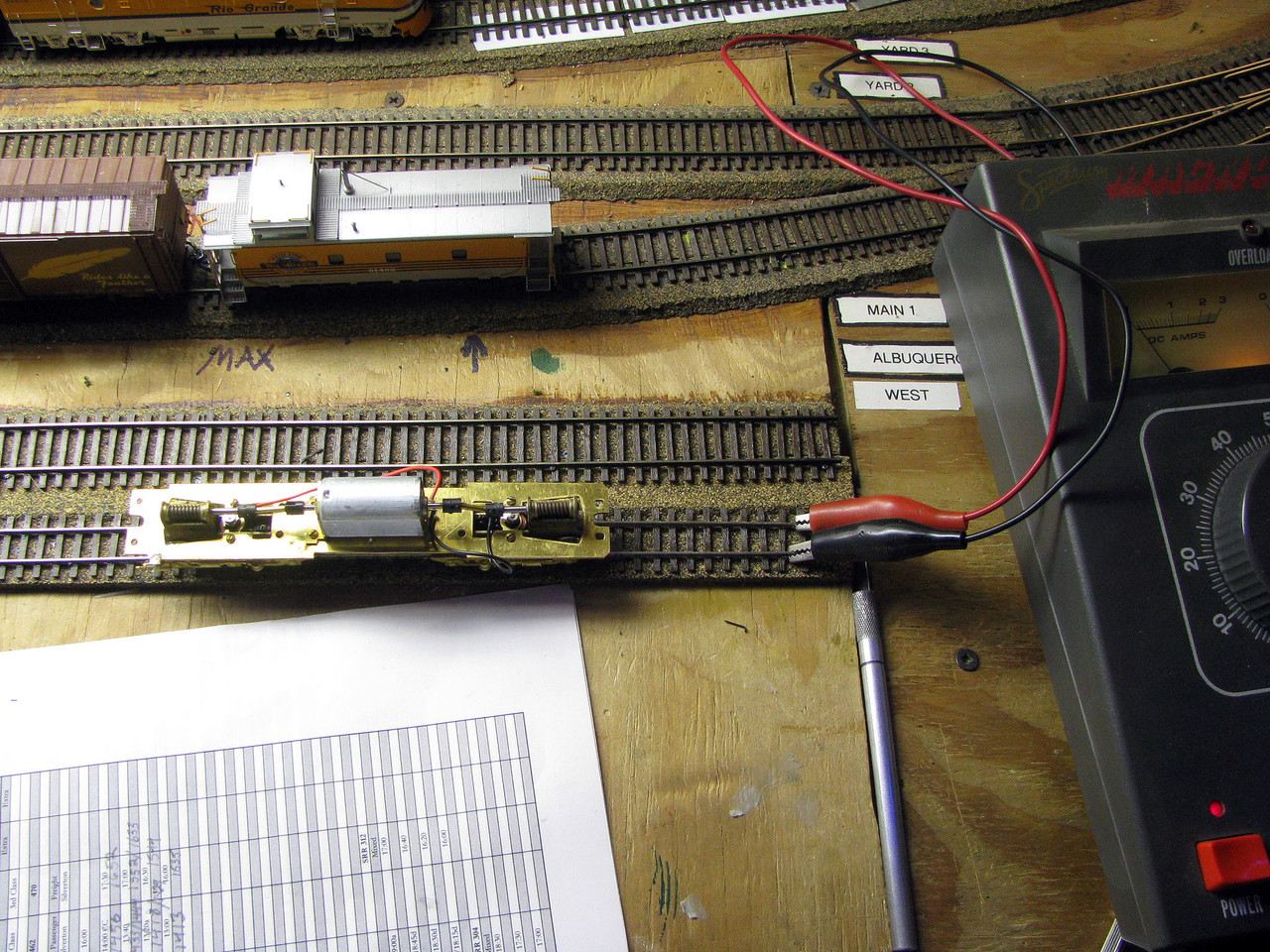

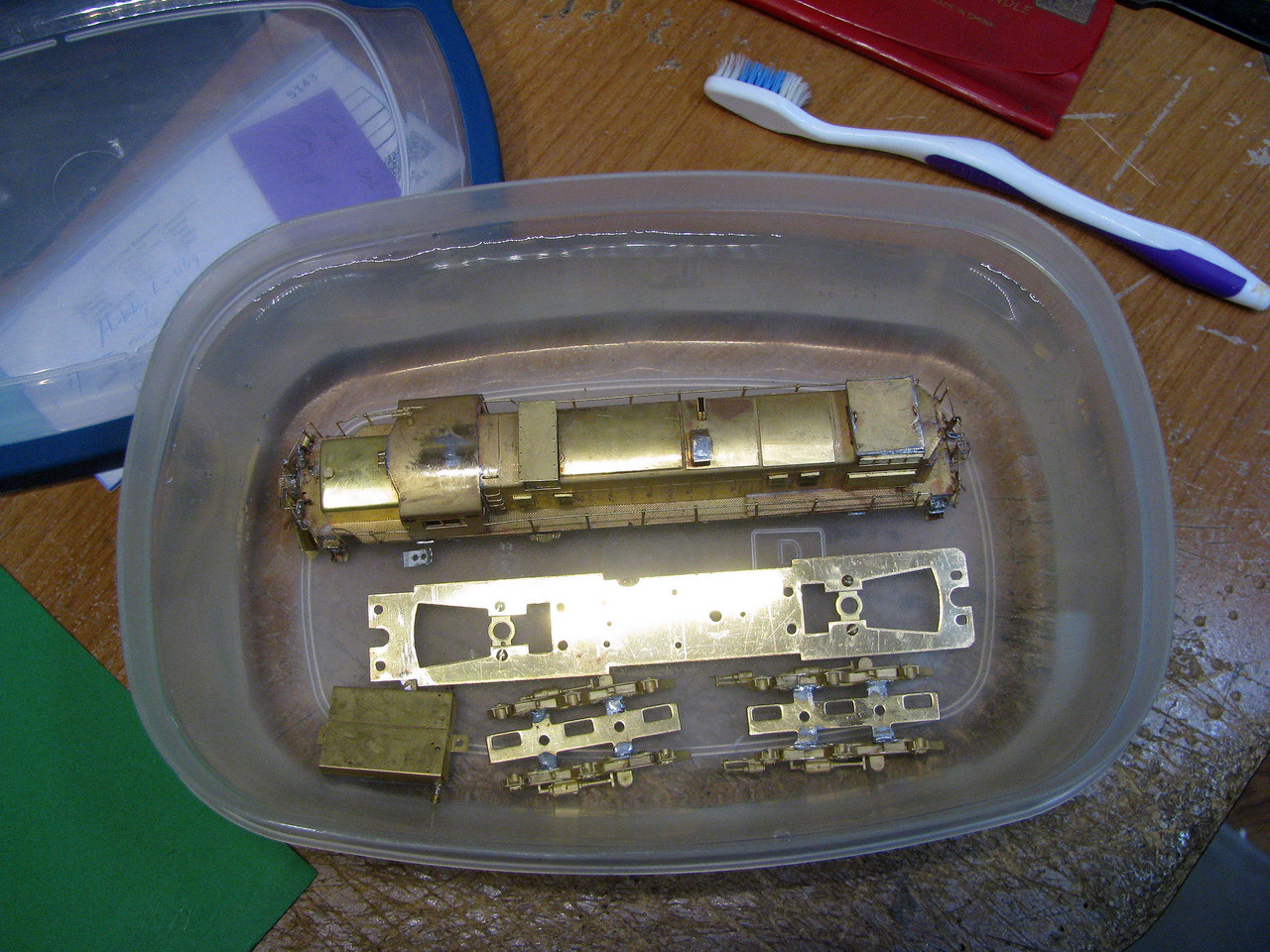

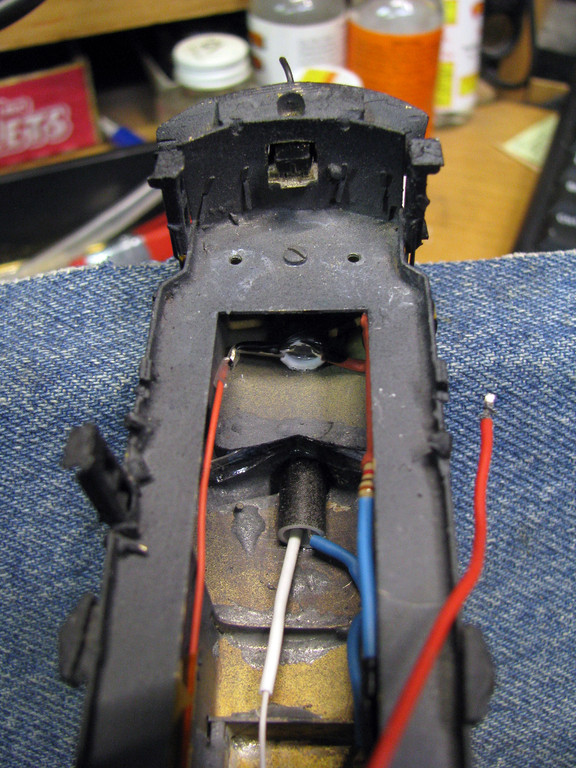

When you start off, this is what you find in the box.

Note the "instructions