Might sound silly, but I want to be able to manually move my switches from both sides. Is there some way to mount a rod beneath the table and then run a stringer (lack of a better word) up to the throw for the switch? Any ideas? FWIW I’m modeling in HO.

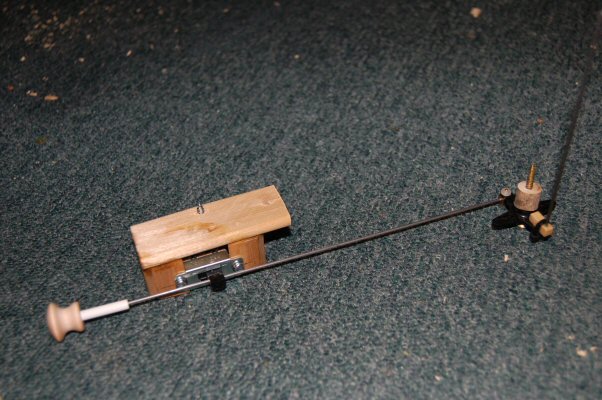

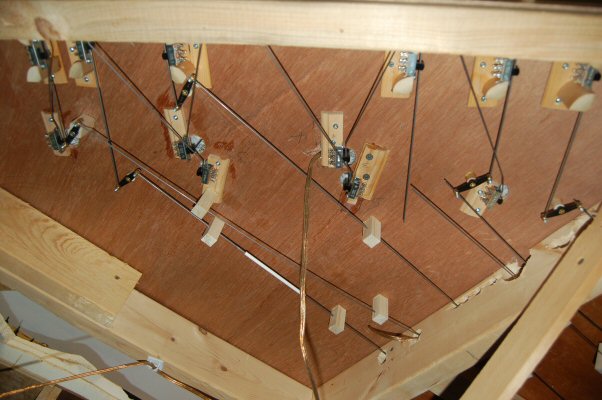

I have a fair reach from the level of my fascia up to the highest turnouts. I wanted manual control. What I did was to fashion blocks sliding in other blocks with a coat hanger wire push rod coming out through a suitably small hole in the fascia. The wire rod attachs at a curled end to a screw on the side of the sliding block which also serves as a stop so that I know when to stop shoving in order to prevent breaking throw rods or the solders holding my point rails to the copper clad PCB ties (I hand lay my turnouts).

To recap, wire rod to screw on side of wooden block that slides in between three others that form a hollow square of sorts. At the end of the wooden block that slides, a wooden slat like you might find inside the lower seam of an older window blind, is screwed vertically on the end of that block. At the top of the slat is a thin nail that rises up to the hole in the throw bar.

Works well, and was very inexpensive to do. Took some time and patience, and some fiddling to get it to work reliably, but I persevered and it is now a pleasure to operate.

I connect my manual switch pushrods to the turnout points with an Anderson link - a Z-shaped lever that extends throught the roadbed and subgrade in a piece of tubing. The tubing is about 1/2 inch from the throwbar, and the pushrod can be adjusted on the lower arm to get the throw distance and point tension right. I make the actual z-lever out of an un-bent paper clip and adjust it with long-nose pliers.

At the fascia end, the pushrod is connected to an electrical switch - both for positive lock and to provide contact sets for live frogs and signaling.

More recently, I’ve been experimenting with fishing line - one length, connected to the electrical switch, pulls the points to the less usual position, another, with a weight hanging off it, holds the points in normal position when there’s no tension on the other line.

Hope this has been useful.

Chuck (modeling Central Japan in September, 1964)

This Link has several pics of how I did it using R/C Aircraft control rods and clevices

http://www.trainboard.com/railimages/showgallery.php?cat=1678

The system works very well

Fergie

If you mean from both sides of say an island, 180 degress opposite, have a look at how Wolfgang Duddler did this.

http://www.westportterminal.de/manualturnout.html

Conceivably, one could extend the control rod straight out the other side with a ball on it as well - push from one side, pull from the other and vice-versa.

Regards,

Sry the link didn’t work so I’ll post pics

The beauty of having a slide switch is two fold. 1) controls signals and indicator lights. 2) The switch keeps the turnout in one position.

Hope this helps

Fergie

I’d be interested in seeing pictures of this.

Thanks for the other responses folks. I got some good ideas from this. Any more are appreciated!

Free-mo modules are required to be able to be flipped end-for-end in a set up and operated from either/both sides. Turnouts with electrical motors need controls on both sides. For manual turnouts, ground throws by the turnout, or Blue Point turnout controllers under the surface, both serve to enable throwing the turnout from either side. The Blue Point controllers are already set up for push/pull operation from both sides. Or, you can design manual devices that work similarly to the Blue Point.

hope this helps

Fred W